Electric pulse regression treatment method for aluminum alloy

A processing method, electric pulse technology, applied in the field of electric pulse regression processing of aluminum alloy, can solve the problems of long heating and holding time, low material temperature rise, material temperature rise, etc., to promote dislocation movement and annihilation, material temperature The effect of low rise and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

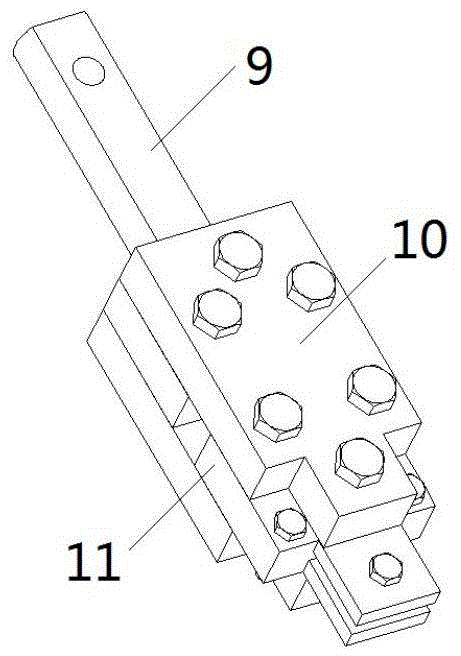

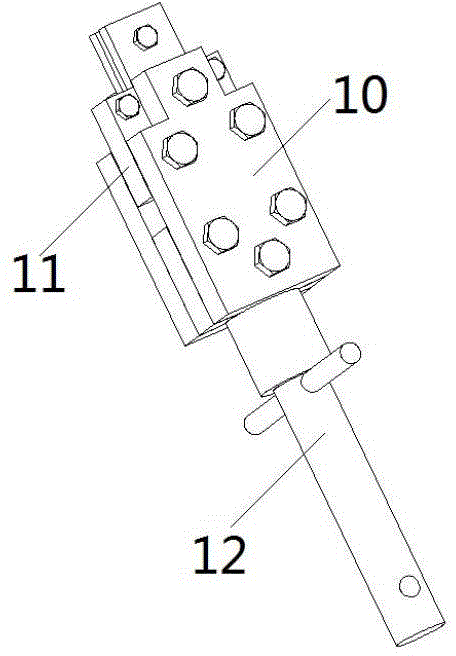

[0028] This embodiment is an electric pulse regression treatment method for aluminum alloys. The electric pulse regression treatment of natural aging aluminum alloy materials is completed by the pulse power supply and an electronic universal testing machine with an insulating chuck, and the temperature of the processed aluminum alloy materials is measured. Mechanical properties: Firstly, the cut single-tension test piece is heat-preserved at 497°C for 45 minutes for solution treatment, and then quenched in 20°C water within 3 seconds after being out of the furnace, and then aged at room temperature for 10 days to obtain a one-way Tensile test piece; pulse current is applied to the natural aging aluminum alloy single pull test piece, the pulse current is generated by the pulse power supply, the output electric pulse is in the form of pulse square wave, the maximum output current is 2000A, the pulse output time and pulse interval can be Adjustment, after the square wave pulse is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com