Cu-Ni-Si alloy material and cooling roller sleeve containing alloy

A technology of cu-ni-si and alloy materials, which is applied in the field of preparation of cooling roll sleeves, amorphous and nanocrystalline strips, can solve the problems of low strength of chromium-zirconium-copper and poisonous elements in beryllium-copper, and reduce the surface Effects of roughness, low cost, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

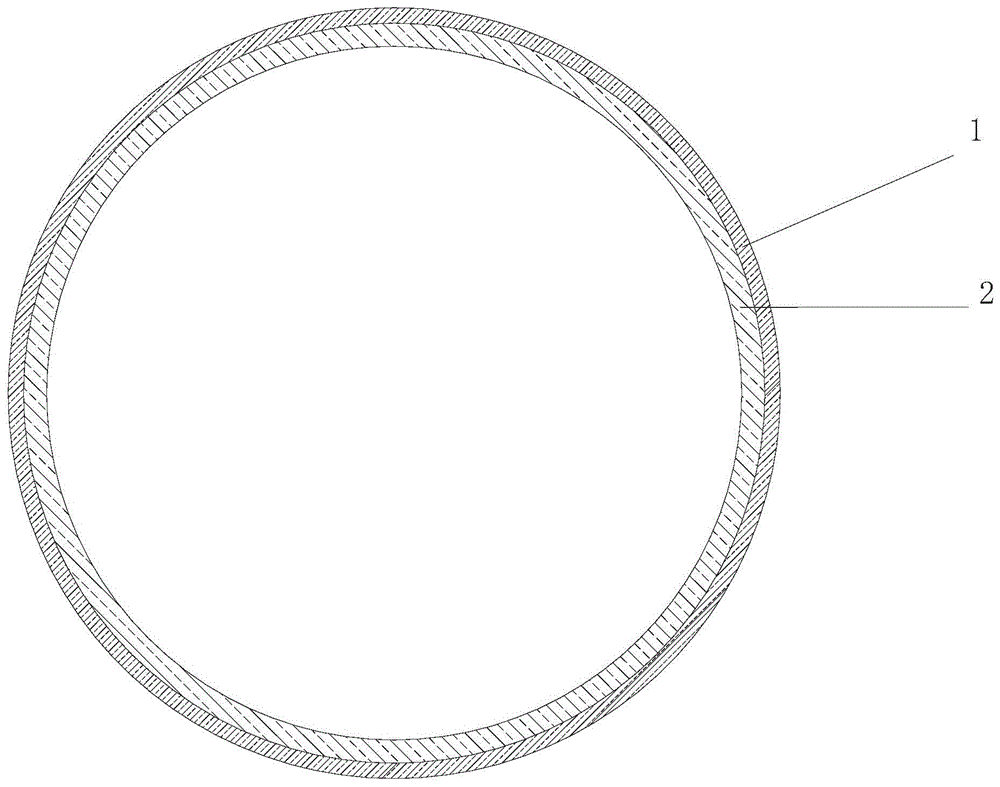

Image

Examples

preparation example Construction

[0031] The preparation method of the Cu-Ni-Si alloy material includes melting, casting, forging and heat treatment steps, wherein:

[0032] In the smelting and casting step, place the elemental components of each component in an induction melting furnace for smelting according to the specified component distribution ratio, and then pour the smelted Cu-Ni-Si alloy liquid to obtain a slab;

[0033] In the forging step, the slab is hot forged at a temperature range of 720-920°C (such as 730°C, 750°C, 800°C, 850°C, 870°C, 900°C, 910°C). Ni 2 Uniform and refined Si grains improve material strength;

[0034] In the heat treatment step, aging treatment is carried out after solid solution, wherein the solid solution temperature is 820-980°C (such as 830°C, 860°C, 880°C, 910°C, 950°C, 970°C), and the aging temperature is 420°C. ~500°C (such as 430°C, 450°C, 480°C, 490°C), this heat treatment method can precipitate Ni that plays a strengthening role 2 Si precipitates, thereby increas...

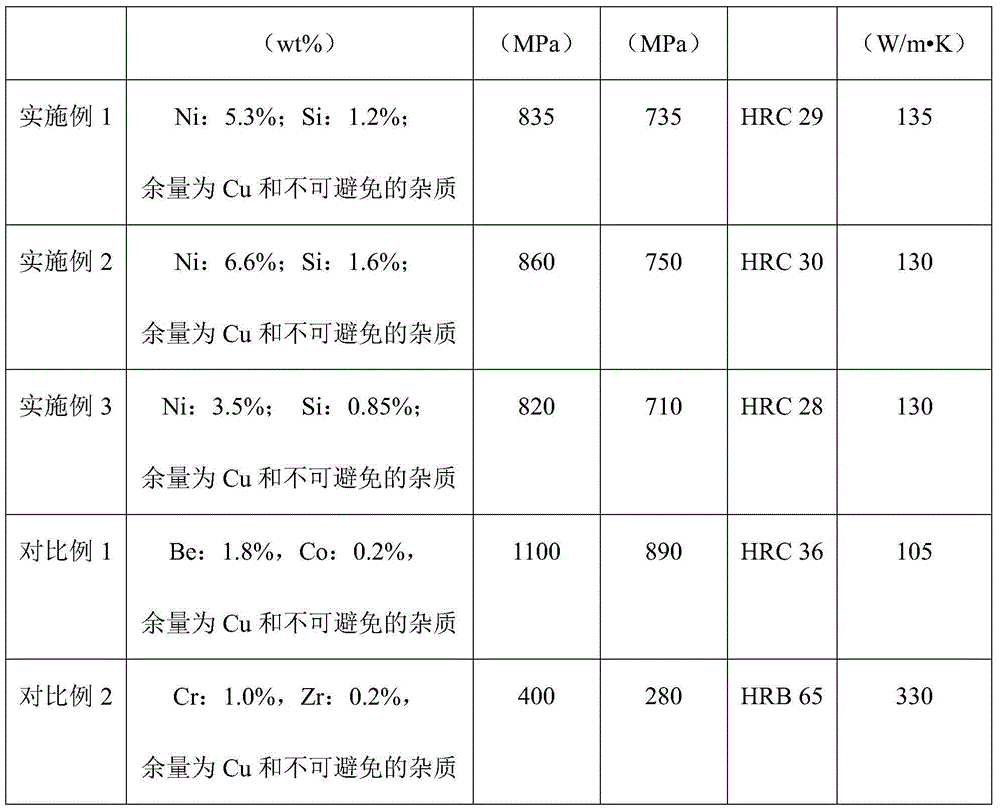

Embodiment 1

[0038] The Cu-Ni-Si alloy prepared in this embodiment is composed of the following components by weight percentage: Ni: 5.3%; Si: 1.2%; the balance is Cu and unavoidable impurities.

[0039] The preparation method of present embodiment Cu-Ni-Si alloy material is as follows:

[0040] (1) Melting and casting Put nickel powder, silicon powder and copper block into an induction melting furnace for melting according to the weight ratio of the above components, and then pour the smelted Cu-Ni-Si alloy liquid to obtain a slab;

[0041](2) Forging The billet is hot forged, cooled to room temperature after hot forging, wherein the initial forging temperature is 900°C, and the final forging temperature is 800°C; during the forging process, it is necessary to complete punching and hole expansion;

[0042] (3) The heat treatment adopts the heat treatment process of solid solution + aging. The forging after hot forging is heated to 900°C for solution treatment, and after holding for 2 hour...

Embodiment 2

[0045] The Cu-Ni-Si alloy prepared in this embodiment is composed of the following components by weight percentage: Ni: 6.6%; Si: 1.6%; the balance is Cu and unavoidable impurities.

[0046] The preparation method of the Cu-Ni-Si alloy material in this example is the same as that in Example 1, and the thickness of the obtained annular alloy material is the same as in Example 1. The properties of the alloy material prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com