PC/PBT alloy material as well as preparation method and application thereof

A technology of alloy materials and raw materials, applied in the field of PC/PBT alloy materials and their preparation, can solve the problems of large molding shrinkage rate of finished products, insufficient high temperature rigidity, low impact strength, etc., so as to overcome poor flow properties and make up for low impact resistance. , the effect of overcoming wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the PC / PBT alloy material of one embodiment, comprises the following steps:

[0032] According to the above-mentioned parts by mass, each component is raw material;

[0033] Premixing the PC, PBT, SEBS, toughening agent, compatibilizer, transesterification inhibitor, antioxidant and lubricant to obtain a premixture; and

[0034] The pre-mixture is extruded and granulated to obtain PC / PBT alloy material.

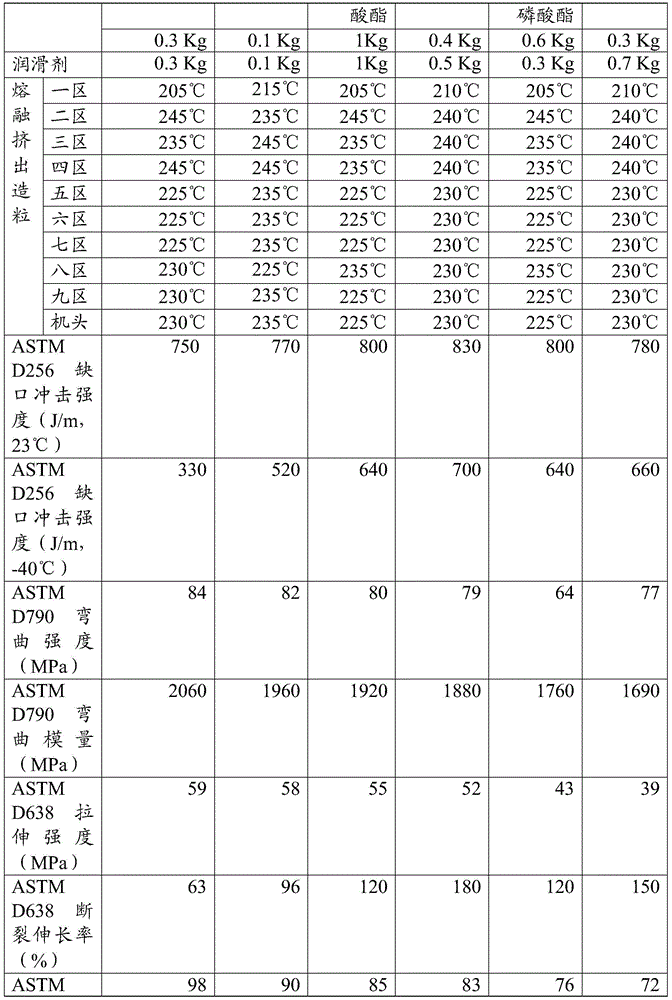

[0035] Further, the device used for extruding and granulating the pre-mixture is a twin-screw extruder, where the pre-mixture is melted and then extruded and granulated. The twin-screw extruder is divided into nine zones from zone 1 to zone 9 according to the feeding sequence. Zone 1 is the most advanced feeding area, and the die head is the last feeding area. The temperature settings of each section of the twin-screw extruder are as follows: zone one 205-215°C, zone two 235-245°C, zone three 235-245°C, zone four 235-245°C, zone five 225-235...

Embodiment 1

[0043] 70Kg of PC after dry pretreatment, 20Kg of PBT, 2Kg of SEBS, 6Kg of polysiloxane-methyl methacrylate copolymer, 0.5Kg of SBS-MAH, 0.8Kg of sodium dihydrogen phosphate, 0.1 Kg of 2,6-tertiary butyl-4-methylphenol and 0.1 Kg of silicone powder were added into a high-speed mixer for pre-mixing to obtain a pre-mixture. Put the mixed pre-mixture in a twin-screw extruder to melt, extrude and granulate. The temperature settings of each section of the twin-screw extruder are: 215°C for the first zone, 235°C for the second zone, and 245°C for the third zone. The fourth zone is 245°C, the fifth zone is 235°C, the sixth zone is 235°C, the seventh zone is 235°C, the eighth zone is 225°C, the ninth zone is 235°C, and the machine head is 235°C to obtain PC / PBT alloy materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com