Polymer anti-crack mortar and its preparation method and application

An anti-cracking mortar and polymer technology, which is applied in the field of polymer anti-cracking mortar and its preparation, can solve the problems of deteriorating sensory perception and reducing the durability of buildings, etc., and achieve the effect of convenient material acquisition, easy operation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

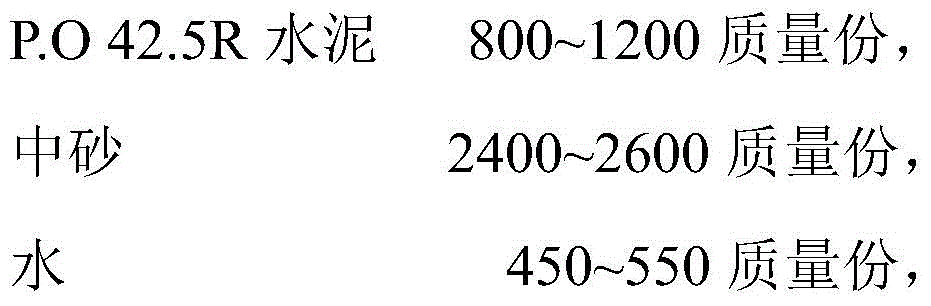

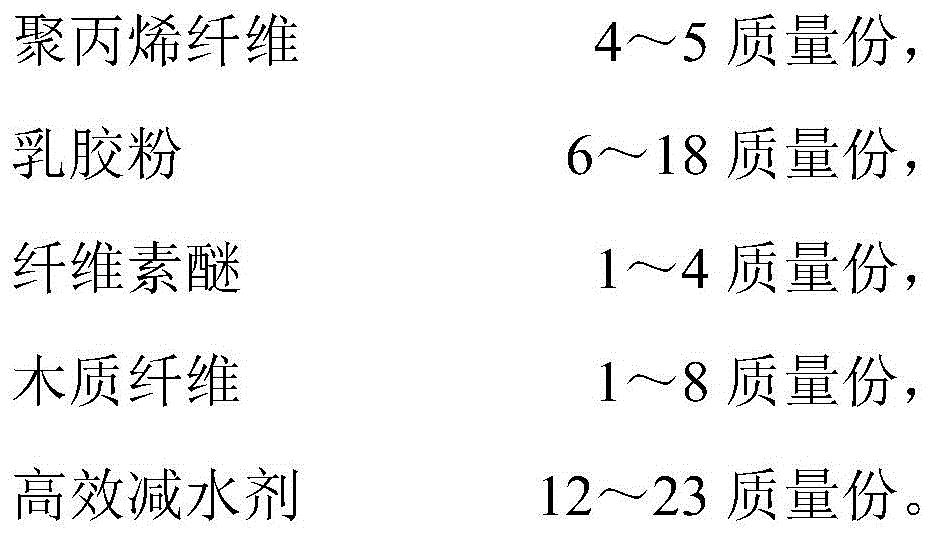

[0055] The content of each component of the polymer anti-cracking mortar in the present embodiment is as follows:

[0056] P.O 42.5R cement 1000kg; medium sand 2500kg; water 500kg; polypropylene fiber 4.5kg; latex powder 12kg; cellulose ether 3.5kg; wood fiber 5kg; superplasticizer 23kg. Wherein, the medium sand is used after pretreatment, and the pretreatment is to pass through a sieve with a diameter of 2.5 mm to screen out sand particles with a particle diameter greater than 2.5 mm. The high-efficiency water reducer is a naphthalene-based high-efficiency water reducer.

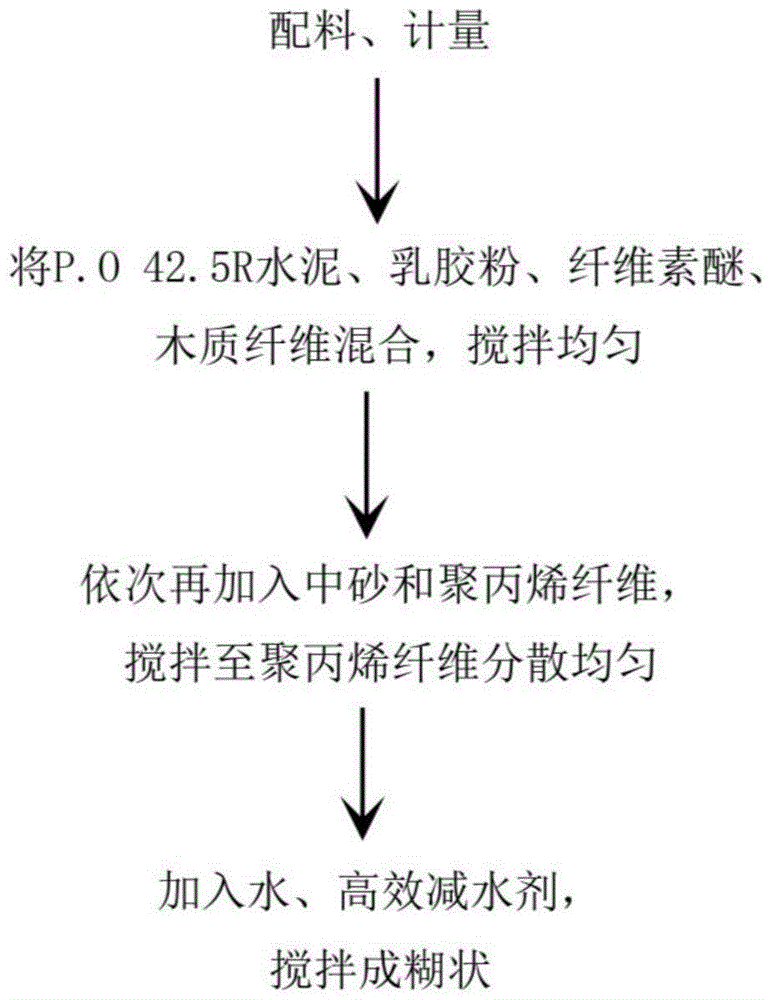

[0057] The preparation process of the polymer anti-cracking mortar is as follows figure 1 As shown, the specific method is: add P.O42.5R cement, latex powder, cellulose ether, and wood fiber to the mixer, and stir evenly; then add medium sand and polypropylene fiber in turn, and stir until the polypropylene fiber is evenly dispersed; add Water and high-efficiency water reducer are stirred into a paste to ...

Embodiment 2

[0059] The content of each component of the polymer anti-cracking mortar in this example is: P.O 42.5R cement 950kg; medium sand 2500kg; water 450kg; polypropylene fiber 4kg; latex powder 8kg; cellulose ether 2kg; wood fiber 8kg; Dosage 15kg. The high-efficiency water reducer is a polycarboxylic acid-based high-performance water reducer. The middle sand pretreatment method is the same as in Example 1. The preparation method and application of the polymer anti-cracking mortar in this example are the same as those in Example 1.

Embodiment 3

[0061] The content of each component of the polymer anti-cracking mortar in this example is: P.O 42.5R cement 850kg; medium sand 2600kg; water 550kg; polypropylene fiber 5kg; latex powder 15kg; cellulose ether 4kg; wood fiber 3kg; Dosage 12kg. The high-efficiency water reducer is a naphthalene-based high-efficiency water reducer. The middle sand pretreatment method is the same as in Example 1. The preparation method and application of the polymer anti-cracking mortar in this example are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com