A kind of treatment method of phosphorus/phosphine electroplating wastewater

A technology of electroplating wastewater and treatment methods, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other issues, to achieve the effect of reducing sludge production and chemical dosage, reducing treatment costs, and reducing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

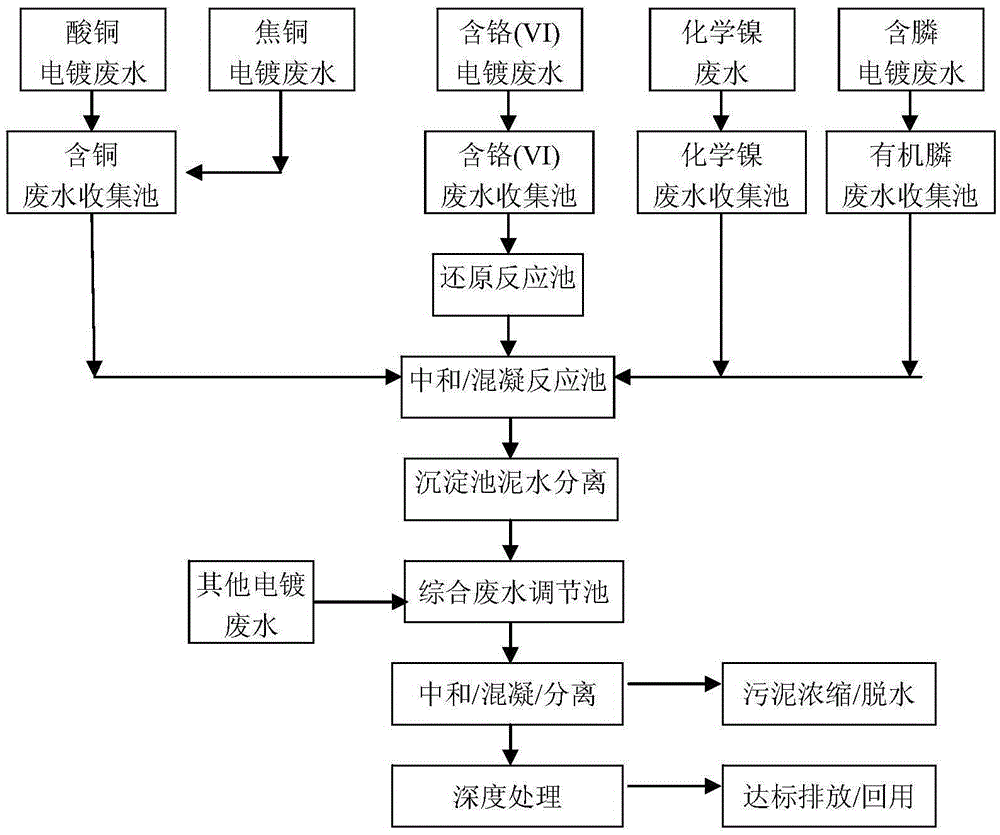

[0025] Embodiment 1 (see figure 1 )

[0026] Classified collection, acid copper electroplating wastewater and pyrophosphorus electroplating wastewater are combined and collected in the copper-containing wastewater collection pool, and chromium-containing electroplating wastewater, chemical nickel, phosphine-containing electroplating wastewater, and pre-treatment wastewater are collected in their respective collection pools.

[0027] The chromium-containing electroplating wastewater is pumped into the hexavalent chromium reduction reaction pool after the water quality and quantity are adjusted in the chromium-containing electroplating wastewater collection pool. One or more of copper electroplating wastewater, chemical nickel wastewater, phosphine-containing electroplating wastewater, etc.), plus a solution of alkaline substances such as milk of lime or sodium hydroxide or sodium carbonate to adjust the pH value to 6.5-11.5, adding polychlorinated After the aluminum / polyacryla...

Embodiment 2

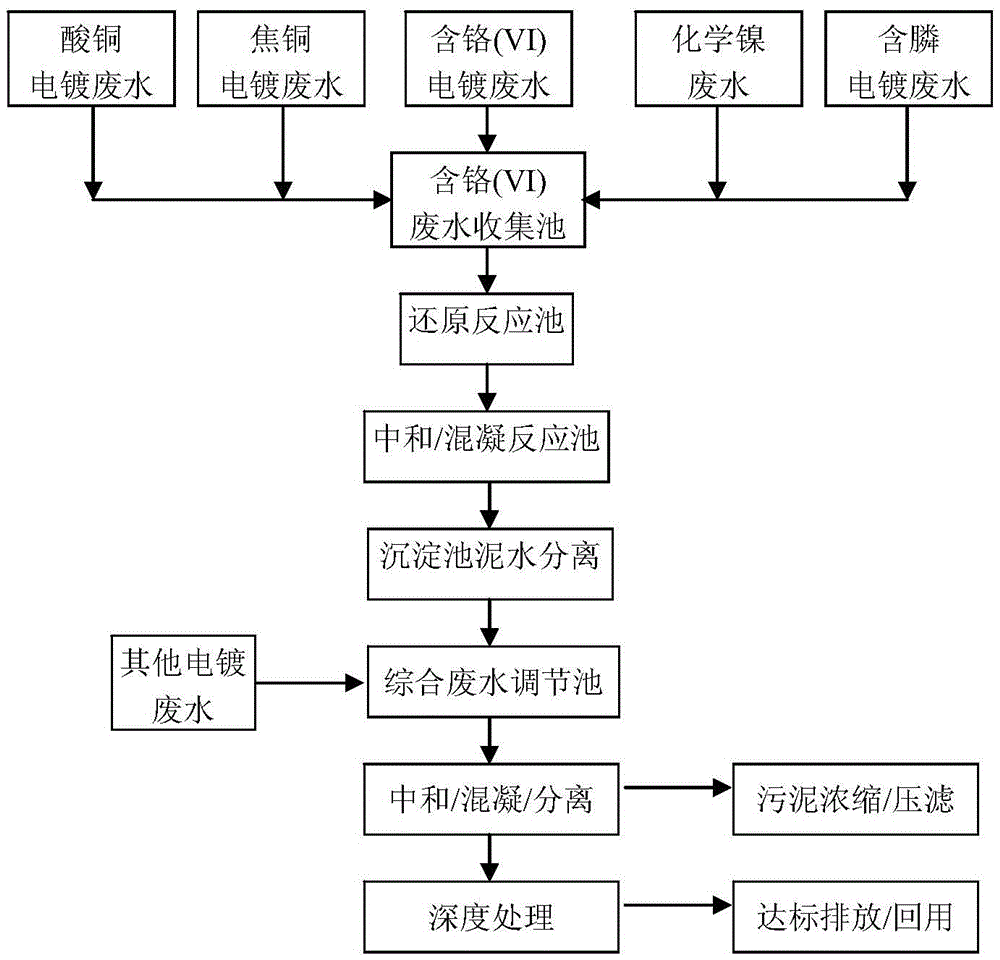

[0029] Embodiment 2 (see figure 2 )

[0030] Mixed collection, coke copper electroplating wastewater, acid copper electroplating wastewater, chromium-containing electroplating wastewater, phosphine-containing electroplating wastewater, chemical nickel wastewater, and phosphine-containing electroplating wastewater are combined and collected in the chromium-containing wastewater collection pool.

[0031] The mixed electroplating wastewater collected by mixing is pumped into the hexavalent chromium reduction reaction tank (secondary reduction) after the water quality and quantity are adjusted in the chromium-containing wastewater collection tank. After the hexavalent chromium reaches the standard, it enters the neutralization reaction tank, and lime or sodium hydroxide or Alkaline substances such as sodium carbonate adjust the pH value to 6.5-11.5. After adding polyaluminum chloride / polyacrylamide for coagulation / flocculation, the wastewater flows into the sedimentation tank for...

Embodiment 3

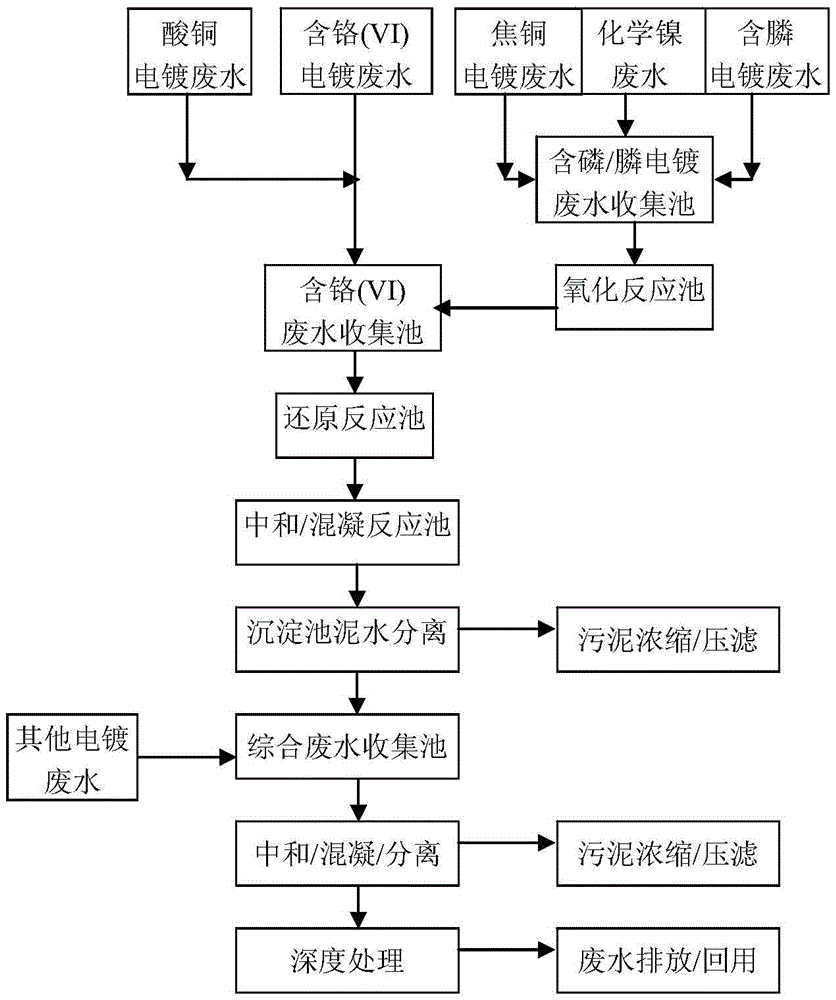

[0033] Embodiment 3 (see image 3 )

[0034] Acidic copper electroplating wastewater and chromium-containing electroplating wastewater are collected in the chromium-containing wastewater collection pool, and phosphorus / phosphine-containing wastewater is collected in the phosphorus / phosphorus-containing electroplating wastewater collection pool (such as burnt copper electroplating wastewater, chemical nickel wastewater, phosphorus-containing electroplating wastewater Wait). Phosphorus / phosphine-containing electroplating wastewater is pumped into the oxidation pool, and oxidants such as sodium hypochlorite solution or hydrogen peroxide or ozone are added to react, and the oxidation-reduction potential is controlled to 450mV-750mV. Phosphorus / phosphine-containing electroplating wastewater is discharged into the chromium-containing wastewater collection pool after oxidation pretreatment.

[0035] The wastewater in the chromium-containing wastewater collection tank is pumped into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com