Method for preparing oil-soluble nano-molybdenum disulfide

A nano-molybdenum disulfide, oil-soluble technology, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of inability to realize large-scale application, and achieve industrial mass production, good repeatability, and simple and fast preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Mix 500 mg ammonium tetrathiomolybdate with 50 g oleylamine.

[0025] 2. The above mixture was stirred at a speed of 500 rpm under the protection of nitrogen with a purity of 99.9%. The mixture was heated to 345 degrees Celsius and kept for 2 hours, then cooled to room temperature to obtain a black liquid.

[0026] 3. Centrifuge the above black liquid for 10 minutes at a centrifugal force of 3000g to obtain a precipitate, and save the supernatant for the next reaction.

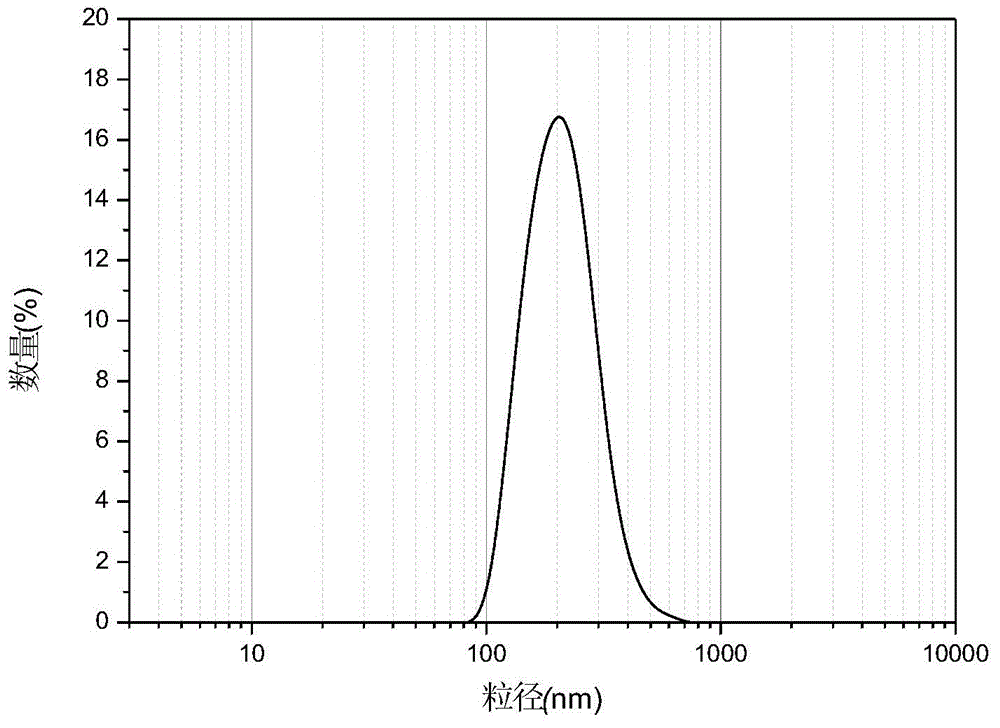

[0027] 4. After washing the precipitate repeatedly with ethanol, the oil-soluble ultra-thin nano-molybdenum disulfide can be obtained, and its particle size is about 200 nanometers.

Embodiment 2

[0029] 1. Mix 500mg ammonium tetrathiomolybdate with 100g oleylamine.

[0030] 2. The above mixture was stirred at a speed of 800 rpm under the protection of nitrogen with a purity of 99.9%. The mixture was heated to 350 degrees Celsius and kept for 1.5 hours, then cooled to room temperature to obtain a black liquid.

[0031] 3. Centrifuge the above black liquid for 8 minutes at a centrifugal force of 4000g to obtain a precipitate, and save the supernatant for the next reaction.

[0032] 4. After washing the precipitate repeatedly with ethanol, the oil-soluble ultra-thin nano-molybdenum disulfide can be obtained, and its particle size is about 200 nanometers.

Embodiment 3

[0034] 1. Mix 1000mg ammonium tetrathiomolybdate with 100g oleylamine.

[0035] 2. The above mixture was stirred at a speed of 1000 rpm under the protection of nitrogen with a purity of 99.9%. The mixture was heated to 355 degrees Celsius and kept for 1 hour, then cooled to room temperature to obtain a black liquid.

[0036] 3. Centrifuge the above black liquid for 5 minutes at a centrifugal force of 5000g to obtain a precipitate, and save the supernatant for the next reaction.

[0037] 4. After washing the precipitate repeatedly with ethanol, the oil-soluble ultra-thin nano-molybdenum disulfide can be obtained, and its particle size is about 200 nanometers.

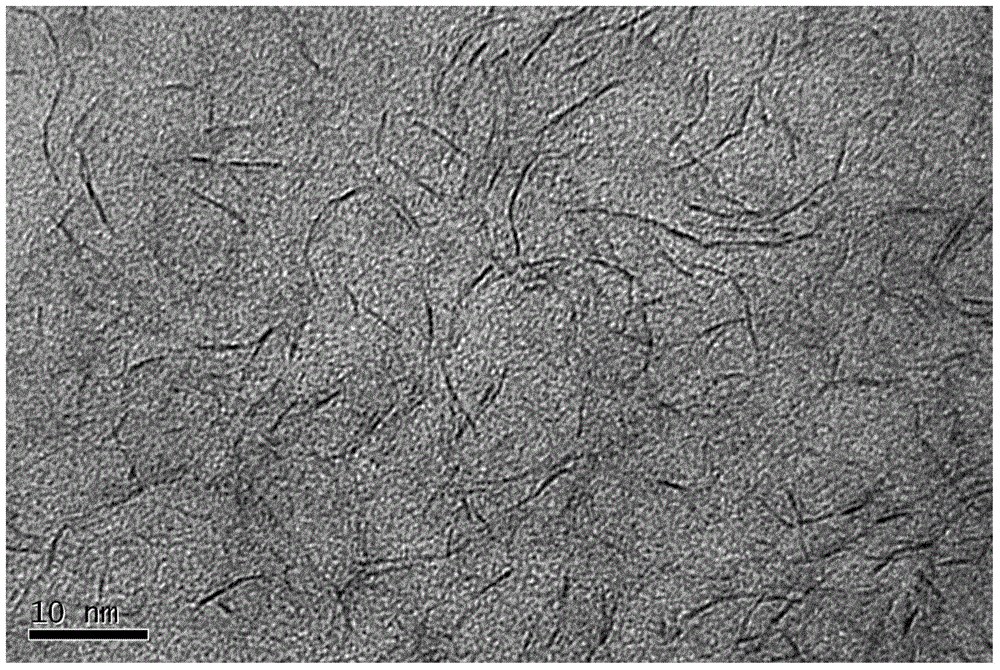

[0038] figure 1 It is the transmission electron microscope figure of the oil-soluble molybdenum disulfide obtained by the preparation method of the present invention. The dark lines in the figure are the edges of the erected molybdenum disulfide layer. Since the dark lines arranged in parallel are hardly observed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com