Preparation method of stannous selenide nanospheres

A technology of tin selenide and nanospheres, which is applied in the direction of nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of secondary environmental pollution, cumbersome reaction steps, and long reaction time, and achieve large output, The effect of high sample purity and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

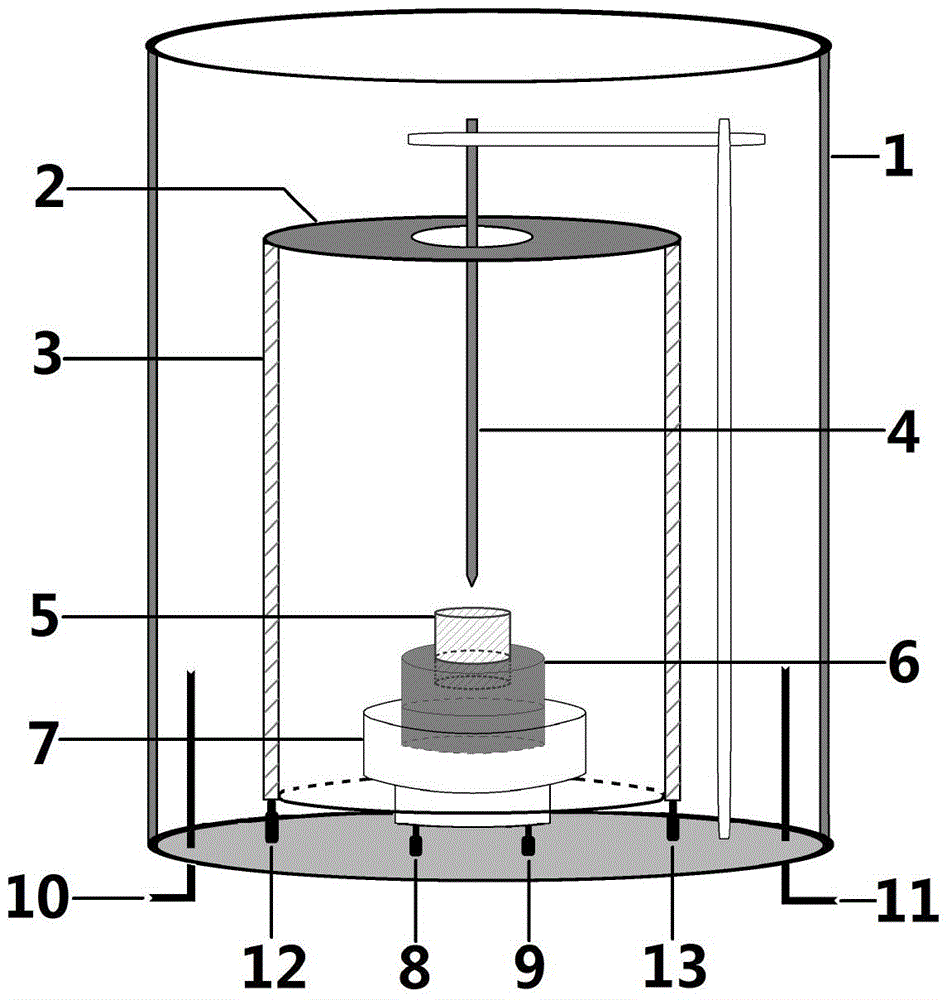

[0026] Example 2 The whole process of preparing the best SnSe nano-faceted sphere.

[0027] The Sn powder and the Se powder with a purity of 99.99% are put into a mixer in a molar ratio of 1.5:1 and mixed evenly. Take out 4.7g of the mixed powder, use a tablet press to briquette, and press into a cylinder with a diameter of 1.8cm and a height of 0.5cm. Put the briquette of the pressed mixed powder into the graphite pot, and then put it into the anode copper pot in the reaction chamber of the DC arc discharge device. The cathode is a tungsten rod electrode. Vacuum the reaction chamber of the DC arc discharge device (preferably less than 1Pa), then fill the mixed gas at 15-20kPa according to the volume ratio of argon: nitrogen = 3:1, and inject circulating cooling water into the condensation wall and copper pot, and start discharge. During the discharge process, keep the voltage at 20V, the current at 100A, and react for 3 to 5 minutes. After the reaction, vacuumize the reac...

Embodiment 3

[0029] Example 3 The whole process of preparing SnSe nanospheres.

[0030] The Sn powder and the Se powder with a purity of 99.99% are put into a mixer according to a molar ratio of 1:1 and mixed evenly. Take out 4.7g of mixed powder, use a tablet press to briquette, and press into a cylinder with a diameter of 1.8cm and a height of 0.5cm. Put the pressed mixed block into the graphite pot, and then put it into the anode copper pot in the reaction chamber of the DC arc discharge device. The cathode is a tungsten rod electrode. Evacuate the reaction chamber of the DC arc discharge device into a vacuum (preferably less than 1Pa), and then fill it with 15-20kPa of nitrogen. The condensation wall and the copper pot are fed with circulating cooling water to start discharging. During the discharge process, keep the voltage at 20V, the current at 100A, and react for 3 to 5 minutes. After the reaction, vacuumize the reaction chamber, then fill it with argon gas of 10-20kpa, passiva...

Embodiment 4

[0031] Example 4 The whole process of preparing SnSe nanospheres.

[0032]The Sn powder and the Se powder with a purity of 99.99% are put into a mixer according to a molar ratio of 1:1 and mixed evenly. Take out 4.7g of mixed powder, use a tablet press to briquette, and press into a cylinder with a diameter of 1.8cm and a height of 0.5cm. Put the pressed mixed block into the graphite pot, and then put it into the anode copper pot in the reaction chamber of the DC arc discharge device. The cathode is a tungsten rod electrode. The reaction chamber of the DC arc discharge device is evacuated (preferably less than 1 Pa), and then filled with 10kPa argon. The condensation wall and the copper pot are fed with circulating cooling water to start discharging. During the discharge process, keep the voltage at 20V, the current at 100A, and react for 5 minutes. After the reaction, add argon to 10-20kpa, passivate the sample in an argon environment for 1-2 hours, and collect a gray-bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com