Method for preparing ordered porous film in orthogonal embossing induction manner

A technology of porous membrane and polymer membrane, applied in the field of microstructure processing of polymer membrane surface, can solve the problems of strict requirements and harsh experimental conditions, and achieve the effect of great flexibility and improved order.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. Inducing the preparation of ordered porous membranes by means of orthogonal embossing includes the following steps:

[0021] Step 1. After mixing the PDMS prepolymer and the crosslinking agent at a mass ratio of 10:1, pour it into a petri dish, and stir it fully with a glass rod to form a uniform prepolymer;

[0022] Step 2. Degas the prepolymer mixed in Step 1 for 1 hour in a circulating water-type multi-purpose vacuum pump, and then heat it at 70°C for 4 hours to dry and solidify to form a PDMS elastomer;

[0023] Step 3, cutting the PDMS elastomer prepared in step 2 into a rectangle of 6cm×2cm;

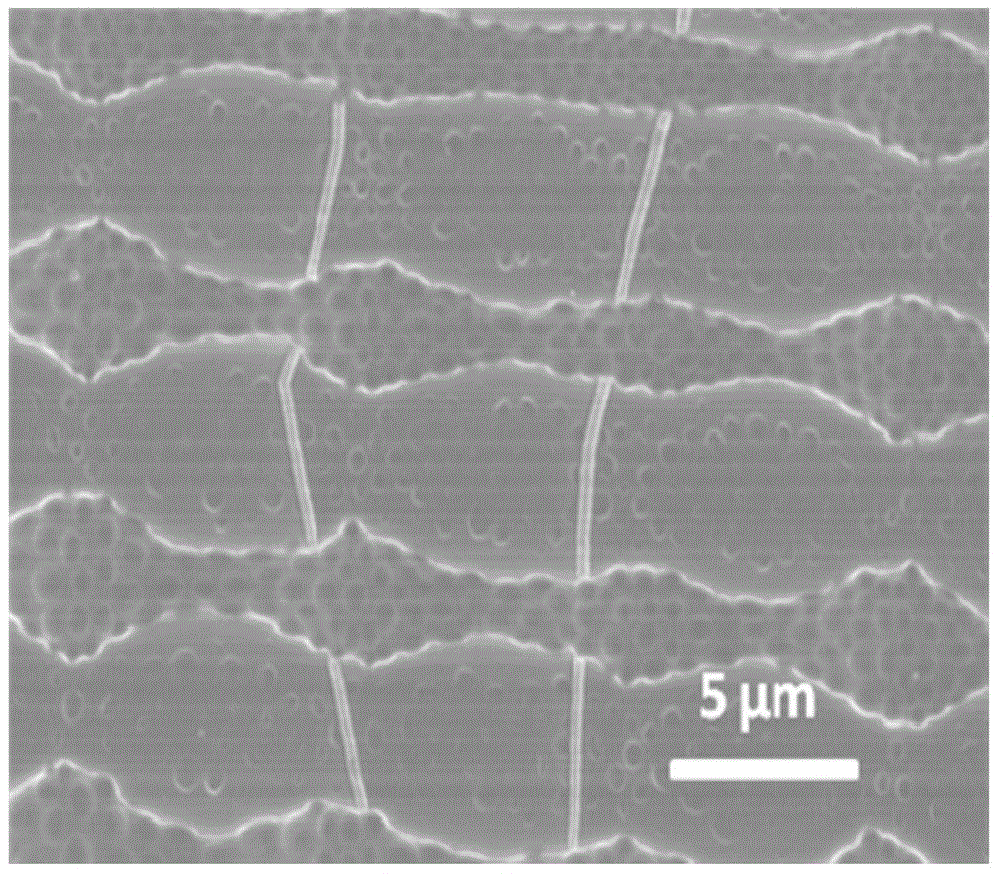

[0024] Step 4. Treat the sheet obtained in Step 3 with oxygen plasma for 30 minutes in a pre-stretched state of 10%, and then retract at a rate of 0.5% / min to obtain a PDMS wrinkle template with striped wrinkles. The wrinkle period is about 7 microns;

[0025] Step 5. Cut the PDMS wrinkle template with striped wrinkles prepared in step 4 into a square of 1 cm×1 ...

Embodiment 2

[0027] Example 2: Inducing the preparation of ordered porous membranes by means of orthogonal embossing, including the following steps:

[0028] Step one to step four are the same as embodiment 1;

[0029] Step 5. Cut the PDMS wrinkle template with striped wrinkles prepared in step 4 into a square of 1cm×1cm, and take 30μl of 50mg / ml PS / THF solution and completely spin-coat it on the cut striped wrinkled template. On one side of the wrinkled PDMS wrinkle template, vacuumize for 1.5h until the solvent evaporates completely, thereby obtaining a polystyrene film on the PDMS wrinkle template;

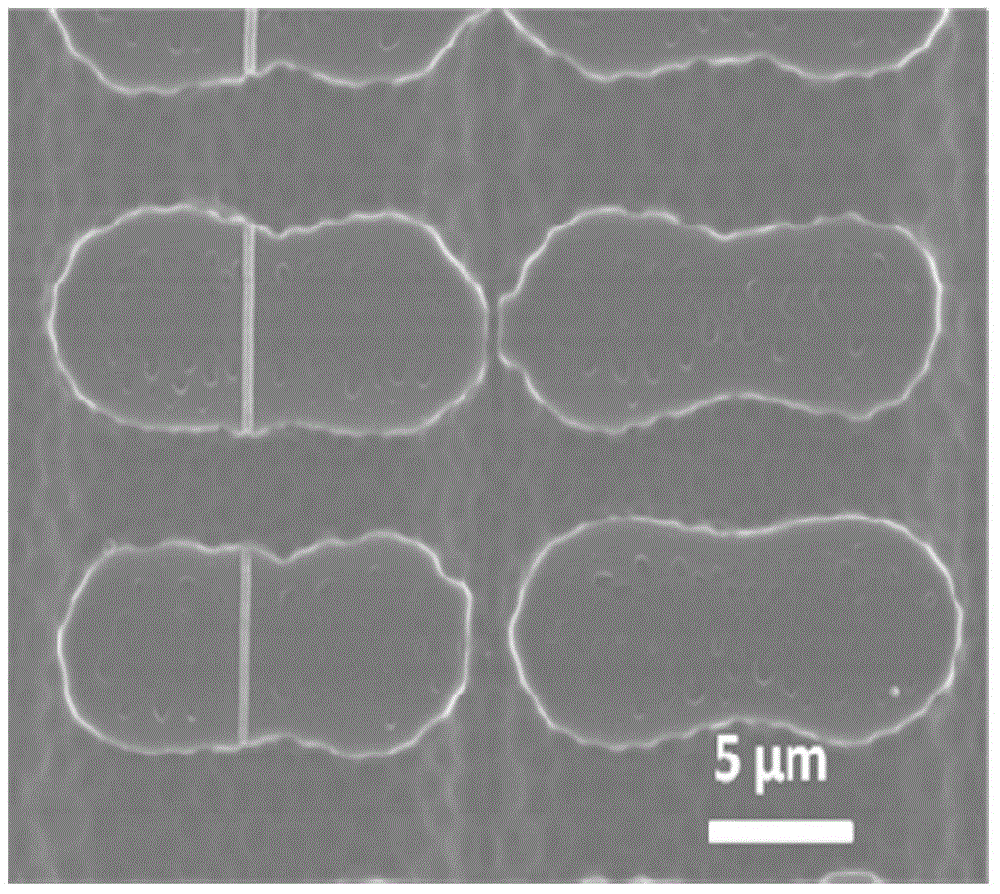

[0030] Step 6, the same as in Example 1, finally, a nanoscale ordered porous structure is formed on the surface of the micron-scale wrinkled structure of the base film, and the pore diameter of the pores is about 600 nanometers. figure 2 It is the SEM image of the 50 mg / ml PS / THF solution spin-coated sample of this example after being induced by a small-period wrinkle template at 140 degr...

Embodiment 3

[0031] Example 3: Inducing the preparation of an ordered porous membrane by means of orthogonal embossing, comprising the following steps:

[0032] Step one to step four are the same as embodiment 1;

[0033] Step 5. Cut the PDMS wrinkle template with striped wrinkles prepared in step 4 into a square of 1cm×1cm, and take 30μl of 60mg / ml PS / THF solution and completely spin-coat it on the cut striped wrinkled template. On one side of the wrinkled PDMS wrinkle template, vacuumize for 2 hours until the solvent evaporates completely, thereby obtaining a polystyrene film on the PDMS wrinkle template;

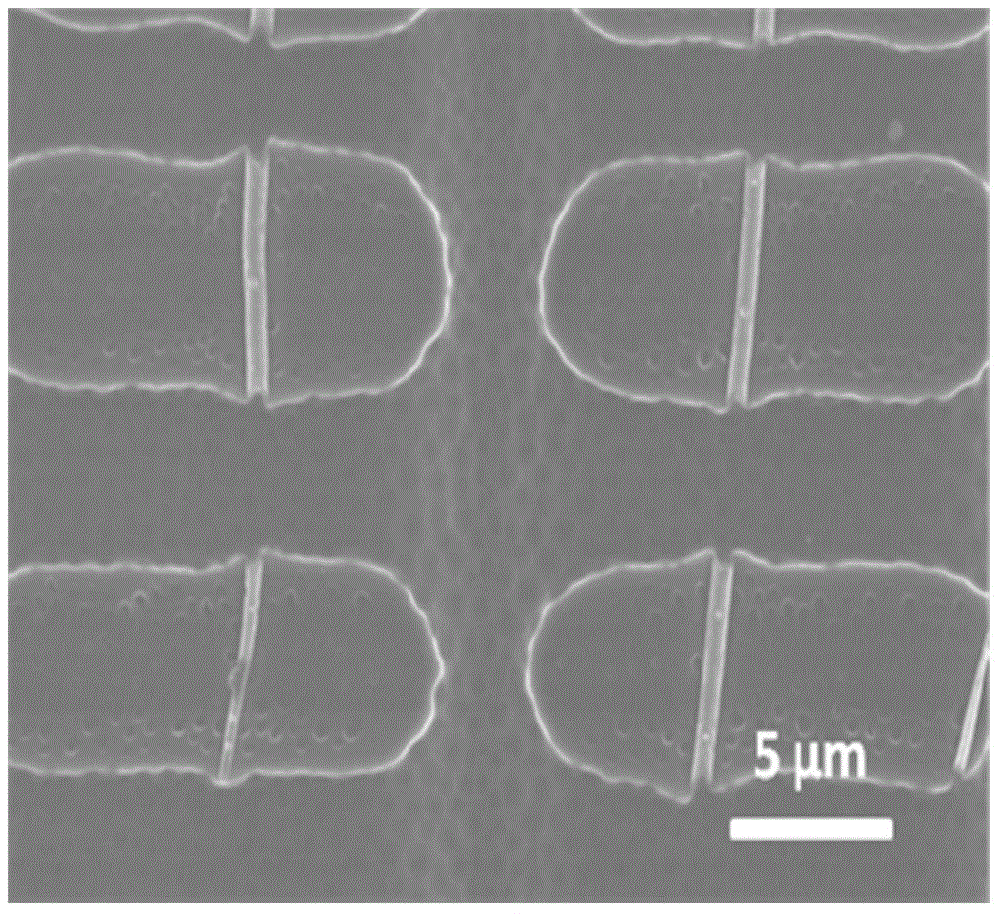

[0034] Step 6. Using the PDMS wrinkle template processed in step 5 as the substrate, the wrinkle template obtained in step 4 and the substrate are in face-to-face contact with each other perpendicular to the wrinkle direction of the template wrinkle and the wrinkle direction of the substrate, and placed at a temperature of 130°C After the two are contacted for 1 hour, the furnace is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com