Artificial stone basement composite stone brick

A composite brick and artificial stone technology, applied in inorganic adhesives, adhesive additives, synthetic resin layered products, etc., can solve the problems of inconvenience, consumption of large marble materials, fear of scratches, etc., and achieve huge economic benefits, Excellent performance, not easy to scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The flaky body made of artificial marble includes three layers: a waterproof surface layer, an unsaturated polyester resin middle layer and a reinforcing bottom layer;

[0023] The waterproof surface layer is made of a mixture of NR3ZP transparent gel coat, retarder TBC (to delay the petrification time, so that the air on the surface gel coat can escape before hardening), and hardener M-50; the mass ratio of the three is 1: 0.03:0.0001.

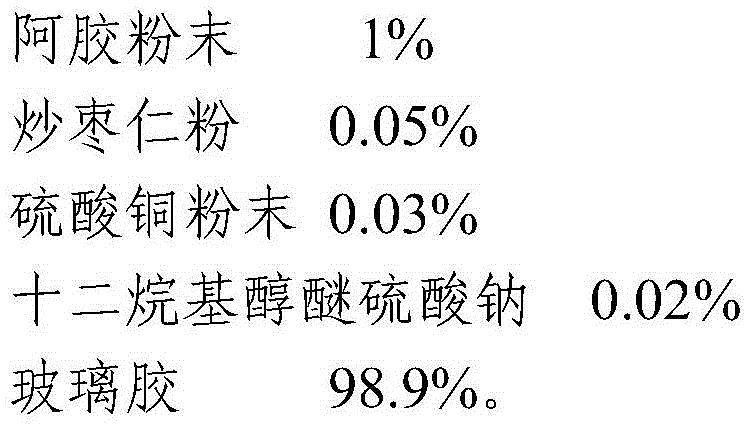

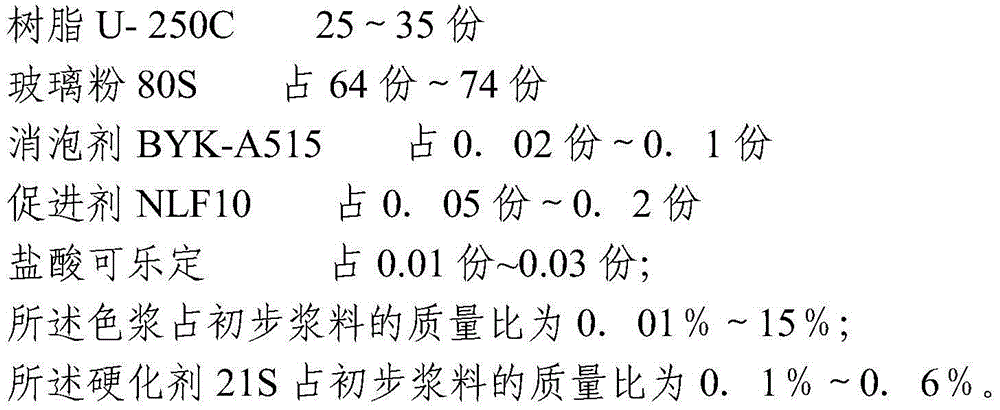

[0024] The unsaturated polyester resin middle layer includes the following raw materials: preliminary slurry, color paste, hardener; wherein the preliminary slurry includes resin U-250C, glass powder 80S, defoamer BYK-A515, accelerator NLF-10 and hydrochloric acid Clonidine; wherein the sclerosing agent includes sclerosing agent 21S;

[0025] The reinforcing bottom layer is a mixture of DS396S unsaturated polyester resin and hardener M-50VR, wherein the mass ratio of DS396S unsaturated polyester resin to hardener M-50VR is 1:0.03.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com