Method for simultaneously extracting silybum marianum oil and silymarin from silybum marianum cake

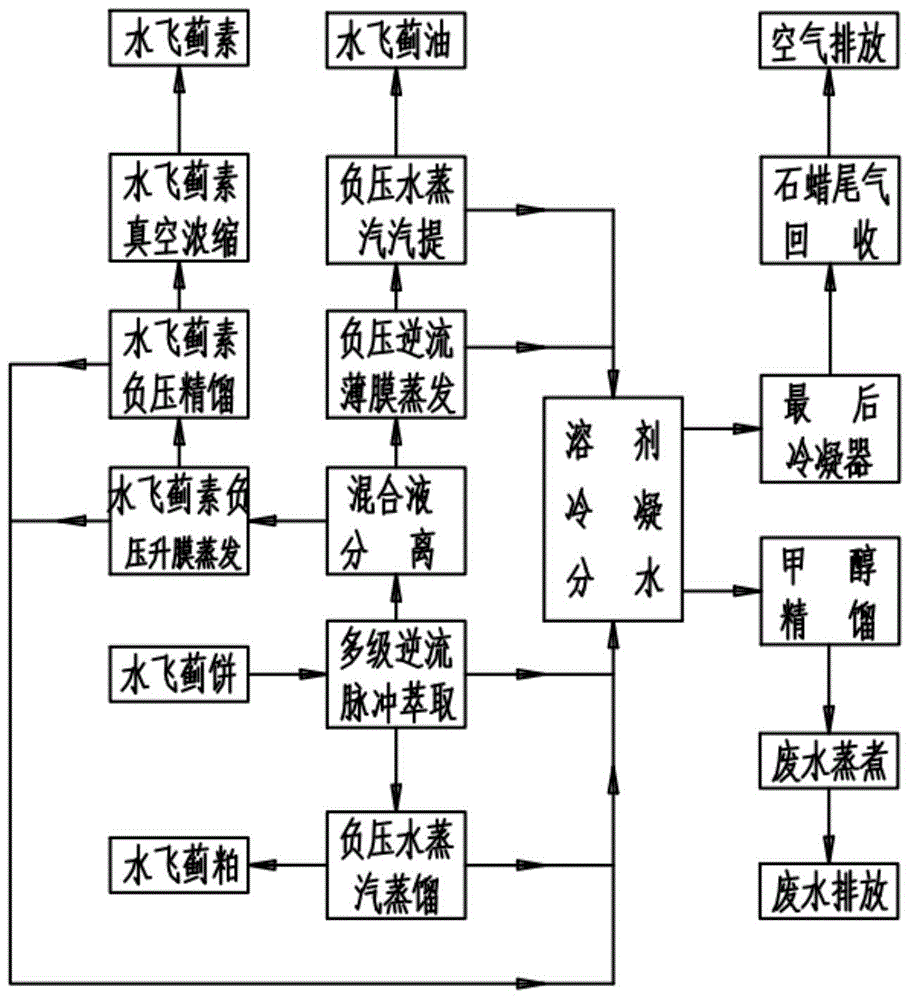

A technology for silymarin and silymarin oil, which is applied in the directions of fat oil/fat production, fat production, organic chemistry, etc., can solve the problems of inability to achieve continuous, industrialized production, environmental pollution, and high production costs, and solves the problem of large solvent input. , no environmental pollution, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

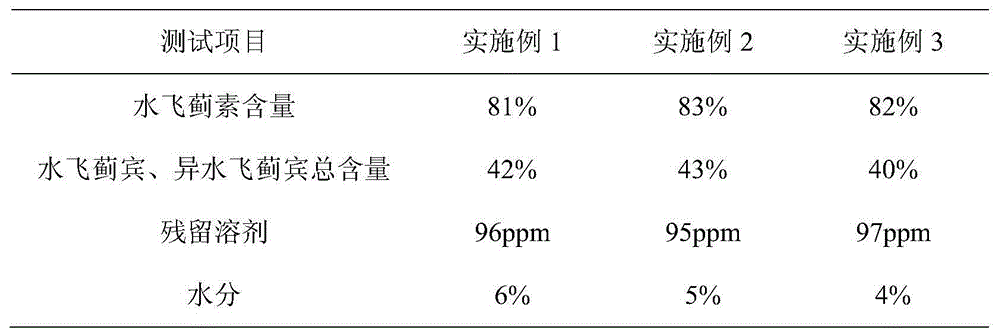

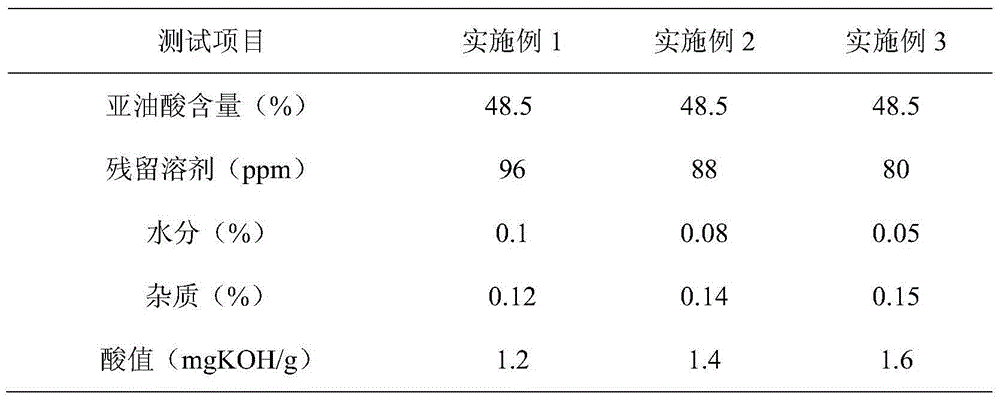

[0040] Embodiment 1: The production method of simultaneously extracting milk thistle oil and silymarin from milk thistle cake of the present embodiment is as follows:

[0041] (a) The cold-pressed milk thistle cake is transported to the extractor by the material seal conveyor, and at a temperature of 45°C, successively pass through the milk thistle oil with a mass concentration of 15.5%, 13.5%, 9.0%, 5.0%, 2.5%, 1.2%, and 0.4% solvents are subjected to seven-stage spray soaking extraction, and then solvent spray soaking extraction to achieve multi-stage pulse countercurrent extraction. The extraction time is 75min, and extracts containing silymarin oil and silymarin mixed liquid, and the remaining milk thistle pulp;

[0042] Wherein, the solvent used in the extraction process is a mixed solvent of methanol and n-hexane with a mass ratio of 0.6:1, and the mass ratio of solvent to milk thistle cake is 1.5:1;

[0043] After extraction, the residual mass fraction of milk thistle ...

Embodiment 2

[0051] Embodiment 2: The production method of simultaneously extracting milk thistle oil and silymarin from milk thistle cake of the present embodiment is as follows:

[0052] (a) The cold-pressed silymarin cake is transported to the extractor by the material seal conveyor, and at a temperature of 50°C, successively passes through the extractor containing silymarin oil with a mass concentration of 16%, 14%, 10%, 6.0%, 3.0%, 1.6%, and 0.6% solvents are subjected to seven-stage spray soaking extraction, and then solvent spray soaking extraction to achieve multi-stage pulse countercurrent extraction. The extraction time is 120min, and extracts containing silymarin oil and silymarin mixed liquid, and the remaining milk thistle pulp;

[0053] Wherein, the solvent used in the extraction process is a mixed solvent of methanol and n-hexane with a mass ratio of 0.8:1, and the mass ratio of solvent to milk thistle cake is 1.2:1;

[0054] After extraction, the residual mass fraction of ...

Embodiment 3

[0062] Embodiment 3: The production method of simultaneously extracting milk thistle oil and silymarin from milk thistle cake of the present embodiment is as follows:

[0063](a) The cold-pressed milk thistle cake is transported to the extractor by the material seal conveyor, and at a temperature of 55°C, successively pass through the extractor containing milk thistle oil with a mass concentration of 16.5%, 14.5%, 11.0%, 7.0%, 3.5%, 2.0%, and 0.8% solvents are subjected to seven-stage spray soaking extraction, and then solvent spray soaking extraction to achieve multi-stage pulse countercurrent extraction. The extraction time is 180min, and extracts containing silymarin oil and silymarin mixed liquid, and the remaining milk thistle pulp;

[0064] Wherein, the solvent used in the extraction process is a mixed solvent of methanol and n-hexane with a mass ratio of 1:1, and the mass ratio of solvent to milk thistle cake is 1.0:1;

[0065] After extraction, the residual mass fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com