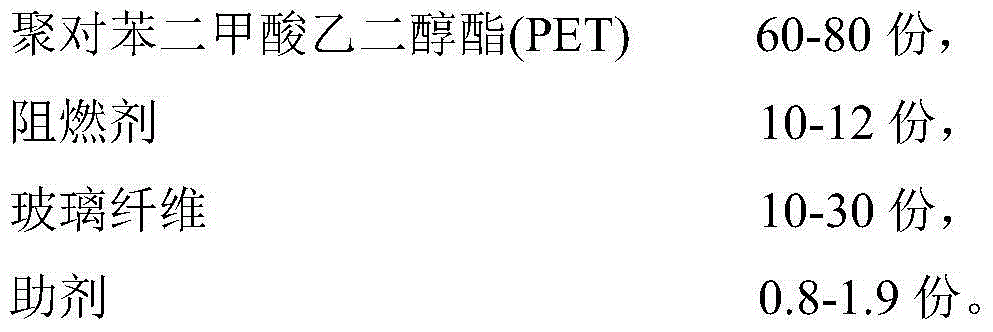

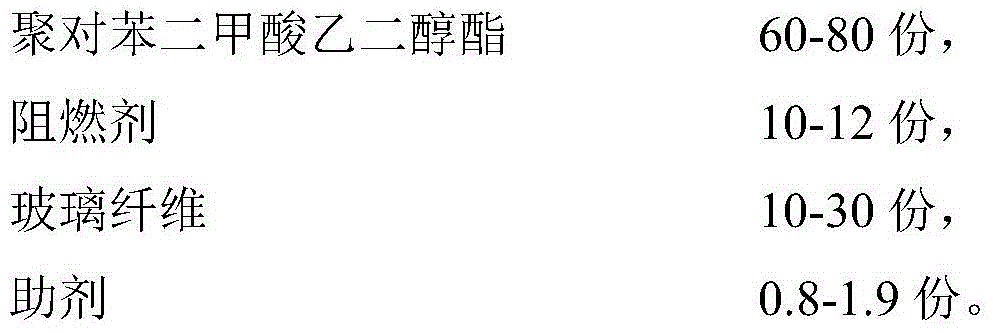

PET material for energy-saving lamp holder and preparation method of PET material

A technology of energy-saving lamps and lamp holders, which is applied in the field of polymer materials, can solve the problems of high prices of nylon and PBT flame-retardant materials, and achieve the effects of low prices, increased Vicat softening point, and increased heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 60 parts of PET, 0.3 parts of silicone, 0.1 parts of antioxidant 1010, 0.2 parts of antioxidant 1076, 0.2 parts of nucleating agent saturated carboxylic acid sodium salt, 6 parts of decabromodiphenylethane and 4 parts of three Antimony oxide (the weight ratio of decabromodiphenylethane to antimony trioxide is 3:2) is mixed with a high-speed mixer at a speed of 800 rpm, at room temperature, and the mixing time is 6 minutes;

[0028] (2) Pour the mixture obtained in step (1) into the main feed port of the screw extruder, and then add 15 parts of continuous glass fiber (12 μm in diameter) through the glass fiber inlet at the rear end to control the temperature of the extruder At 260-280°C, the mixed material is pelletized through a twin-screw extruder to obtain a special PET material for the lamp holder of the energy-saving lamp. The relevant performance tests of the product are shown in Table 1.

Embodiment 2

[0030] (1) Mix 60 parts of PET, 0.3 parts of lubricant PETS, 0.2 parts of antioxidant 1010, 0.4 parts of antioxidant 1076, 0.5 parts of nucleating agent saturated carboxylic acid sodium salt, 9 parts of decabromodiphenylethane and 3 parts Antimony trioxide (the weight ratio of decabromodiphenylethane to antimony trioxide is 3:1) is mixed with a high-speed mixer at a speed of 1000 rpm, at room temperature, and the mixing time is 3 minutes;

[0031] (2) Pour the mixture obtained in step (1) into the main feeding port of the screw extruder, and then add 28 parts of continuous glass fiber (12 μm in diameter) through the glass fiber inlet at the rear end to control the temperature of the extruder At the temperature of 260-280°C, the mixed material can be cut into pellets through a twin-screw extruder to obtain the special PET material for the lamp holder of the product energy-saving lamp.

Embodiment 3

[0033] (1) 78 parts of PET, 0.3 parts of stearyl alcohol, 0.5 parts of antioxidant P262, 0.7 parts of nucleating agent saturated carboxylic acid sodium salt, 8 parts of decabromodiphenylethane and 4 parts of antimony trioxide (decabromodiphenylethane) The weight ratio of diphenylethane to antimony trioxide is 2:1) High-speed mixing with a high-speed mixer, the speed is 800rpm, room temperature, and the mixing time is 6min;

[0034] (2) Pour the mixture obtained in step (1) into the main feed port of the screw extruder, and then add 10 parts of continuous glass fiber (12 μm in diameter) through the glass fiber inlet at the rear end to control the temperature of the extruder At the temperature of 260-280°C, the mixed material can be cut into pellets through a twin-screw extruder to obtain the special PET material for the lamp holder of the product energy-saving lamp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com