2,4-diaminotoluene molecularly imprinted polymer, preparation method and application thereof

A technology of diaminotoluene and molecular imprinting, which is applied in material separation, analytical materials, instruments, etc., can solve the problems of insufficient rigidity of molecularly imprinted polymers, weak binding ability of template molecules, difficult elution of template molecules, etc., and achieve short synthesis time , high specific volume, easy to wash off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

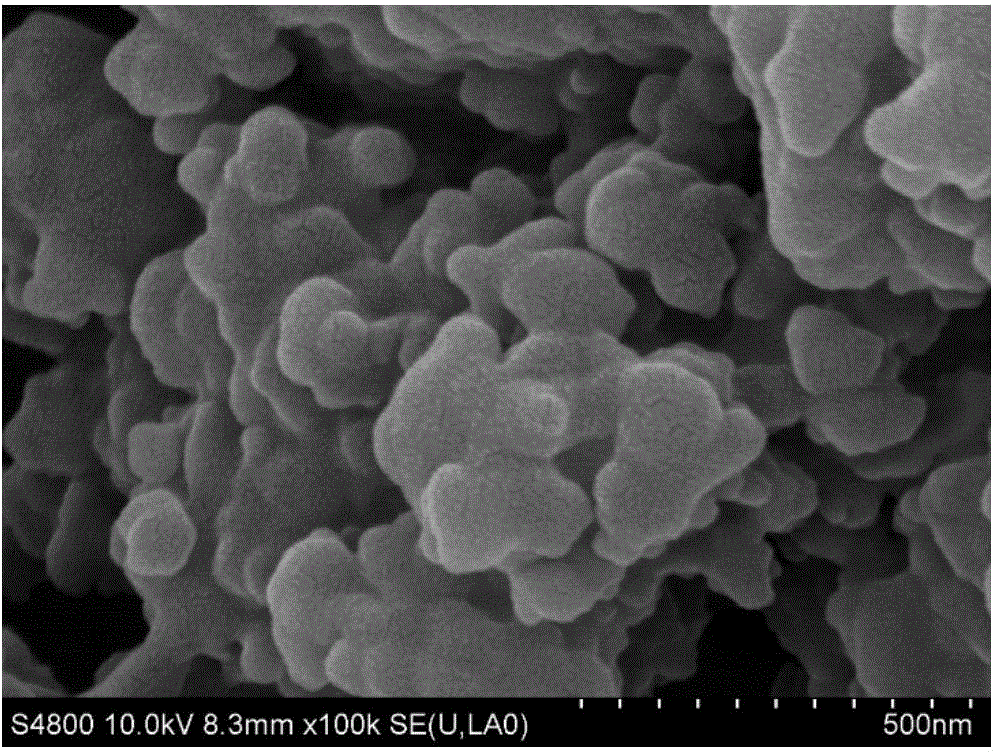

[0038] The second object of the present invention is to provide a method for preparing the 2,4-diaminotoluene molecularly imprinted polymer, comprising the following steps:

[0039] 1) Prepolymerization: Mix the functional monomer methacrylic acid (MAA) and the template molecule 2,4-diaminotoluene at a molar ratio of 3.5-4.5:1, add acetonitrile, and stir the prepolymerization at 30-40°C. get prepolymer;

[0040] 2) Cross-linking: add divinylbenzene and AIBN to the prepolymer described in step 1), pass nitrogen gas for 30-50 minutes, and react at 60-70°C to obtain a cross-linked polymer;

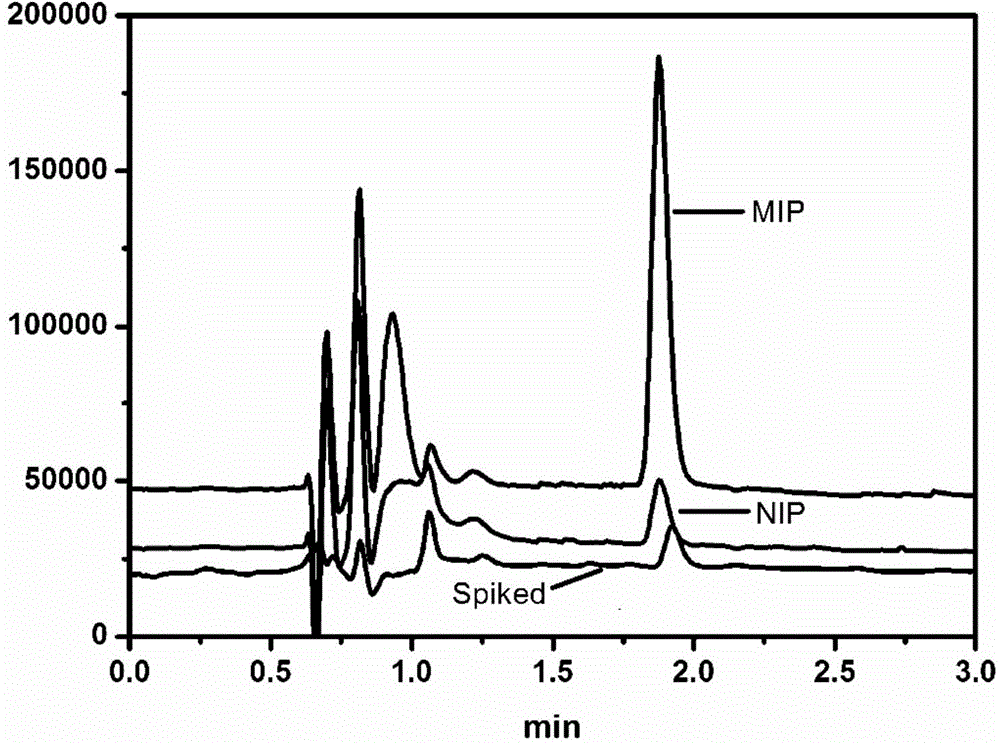

[0041] 3) Washing: using methanol-acetic acid with a volume ratio of (8-10):1 to wash the cross-linked polymer described in step 2), after washing away the template molecules, the target molecularly imprinted polymer (MIP) is obtained.

[0042] The third object of the present invention is to provide the application of the above-mentioned 2,4-diaminotoluene molecularly imprinted polymer in so...

Embodiment 1

[0049] 1) Prepolymerization: Take 2g of functional monomer methacrylic acid (MAA), 0.74g of template molecule 2,4-diaminotoluene, add 30mL of acetonitrile, and stir at 35°C for 4h for prepolymerization to obtain a prepolymer;

[0050] 2) Cross-linking: add 1.6 g of divinylbenzene and 0.03 g of AIBN to the prepolymer described in step 1), pass nitrogen gas for 30 min, and react at 60° C. for 8 h to obtain a cross-linked polymer;

[0051] 3) Washing: Add 60 mL of methanol-acetic acid mixed solvent with a volume ratio of 8:1 to the cross-linked polymer obtained in step 2), perform Soxhlet extraction for 6 h, wash away the template molecules, filter and separate, and obtain the target molecularly imprinted polymer ( MIP).

[0052]Using the Soxhlet extraction method, the template molecules are slowly and more completely released from the cross-linked polymer, without destroying the structure of the molecularly imprinted polymer, and improving the 2,4-diaminotoluene in the sample to...

Embodiment 2

[0054] 1) Prepolymerization: take 1.75g of functional monomer methacrylic acid (MAA), 0.74g of template molecule 2,4-diaminotoluene, add 35mL of acetonitrile, and stir at 30°C for 6h for prepolymerization to obtain a prepolymer;

[0055] 2) Cross-linking: add 1.8 g of divinylbenzene and 0.04 g of AIBN to the prepolymer described in step 1), pass nitrogen gas for 50 min, and react at 65° C. for 6 h to obtain a cross-linked polymer;

[0056] 3) Washing: Add 60 mL of methanol-acetic acid mixed solvent with a volume ratio of 8:1 to the cross-linked polymer obtained in step 2), perform Soxhlet extraction for 6 h, wash away the template molecules, filter and separate, and obtain the target molecularly imprinted polymer ( MIP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com