Method for refining polymethoxy dialkyl ether

A technology of polymethoxydialkyl ethers and products, which is applied in the field of refining process of diesel oil additives-polymethoxydialkyl ethers, can solve the problems that the acid value requirements of the target products cannot be solved at the same time, and achieve easy operation , simple process, mild reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

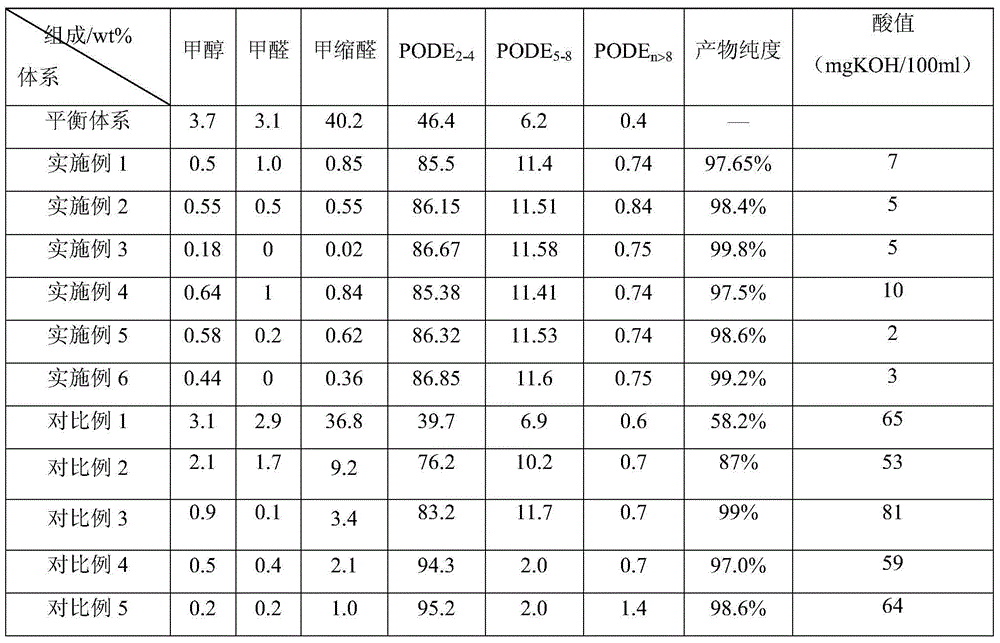

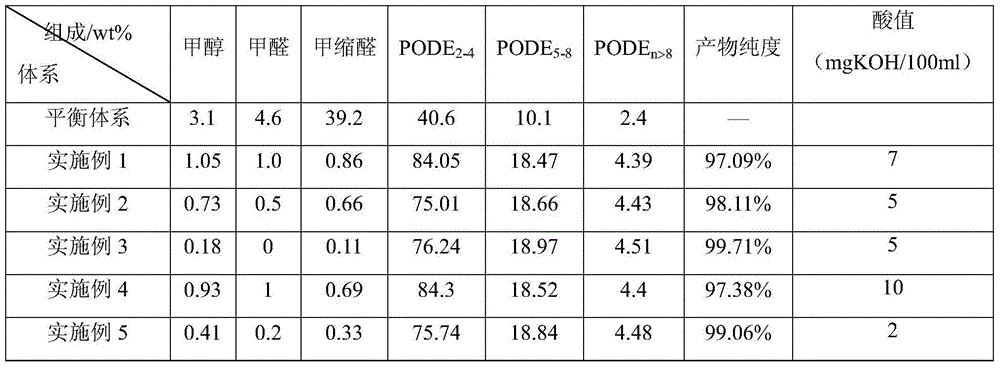

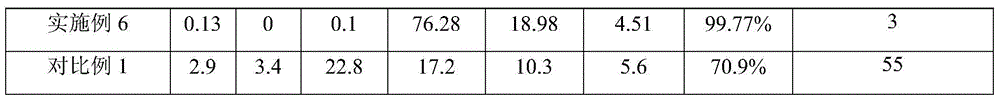

Examples

Embodiment 1

[0050] This embodiment provides a method for refining and purifying polymethoxydialkyl ethers, specifically:

[0051] (1) Put the polymethoxydialkyl ether synthetic liquid into the head tank with the reflux device, and enter the ammonia and aldehyde contactor, and the ammonia gas with a purity of 60% enters the ammonia and aldehyde through the ammonia buffer tank Condensation reaction is carried out in the contactor, the ammonia pressure is controlled to 0.02MPa, the ammonia is measured in excess of 0.1% in terms of molar mass, the condensation reaction liquid enters the tube reactor, and the outlet temperature of the reactor is controlled to 50°C;

[0052] (2) Settling the mixture obtained in step (1) for 8-12 hours, mechanically removing impurities, collecting the reaction solution and placing it in an evaporation crystallization kettle, controlling the vacuum degree in the kettle to be 60-85KPa, and the steam pressure to be 0.1-0.3 MPa, the temperature is controlled at 50-8...

Embodiment 2

[0056] This embodiment provides a method for refining and purifying polymethoxydialkyl ethers, specifically:

[0057] (1) Pour the polymethoxydialkyl ether synthesis liquid into the head tank with a reflux device, and enter the ammonia and aldehyde contactor, and the ammonia gas with a purity of 99.99% enters the ammonia and aldehyde through the ammonia buffer tank Condensation reaction is carried out in the contactor, the ammonia pressure is controlled to 0.05MPa, the ammonia is metered over 0.5%, the condensation reaction liquid enters the tube reactor, and the outlet temperature of the reactor is controlled to 55°C;

[0058] (2) Settling the mixture obtained in step (1) for 8-12 hours. After mechanically removing impurities, collect the reaction solution and place it in an evaporation crystallization kettle. Evaporate and crystallize at 60°C; evaporate the light components in the reaction liquid, such as excess ammonia, water, methanol, ethanol, etc. Constant crystallizati...

Embodiment 3

[0062]This embodiment provides a method for refining and purifying polymethoxydialkyl ethers, specifically:

[0063] (1) Put the polymethoxydialkyl ether synthetic liquid into the head tank with the reflux device, and enter the ammonia and aldehyde contactor, and the ammonia gas with a purity of 75% enters the ammonia and aldehyde through the ammonia buffer tank Condensation reaction is carried out in the contactor, the ammonia pressure is controlled to 0.5MPa, the ammonia is metered over 1.2%, the condensation reaction liquid enters the tube reactor, and the outlet temperature of the reactor is controlled to 70°C;

[0064] (2) Settling the mixture obtained in step (1) for 8-12 hours. After mechanically removing impurities, collect the reaction solution and place it in an evaporation crystallization kettle. Evaporate and crystallize at 80°C; evaporate the light components in the reaction liquid, such as excess ammonia, water, methanol, ethanol, etc. Constant crystallization o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com