Vitrification method of aluminum and filter radioactive waste

A technology of radioactive waste and treatment method, applied in the field of vitrification of aluminum and filter radioactive waste, can solve the problems of unqualified disposal and explosion, and achieve the effect of reducing the volume

Active Publication Date: 2018-04-03

KOREA HYDRO & NUCLEAR POWER CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As for the treatment of radioactive waste of such used filters, after separating the metal frame and filter components, after cleaning the metal frame, compressing the glass fiber and aluminum metal foil, packaging in iron drums is considered, but Due to concerns about the possibility of explosion when storing iron drums and the generation of hydrogen gas at the processing station after storing iron drums (Al+2NaOH→1 / 2Al 2 o 3 +Na 2 O+H 2 ), etc., leading to a decision to dispose of nonconformities, and a plan to stabilize them

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

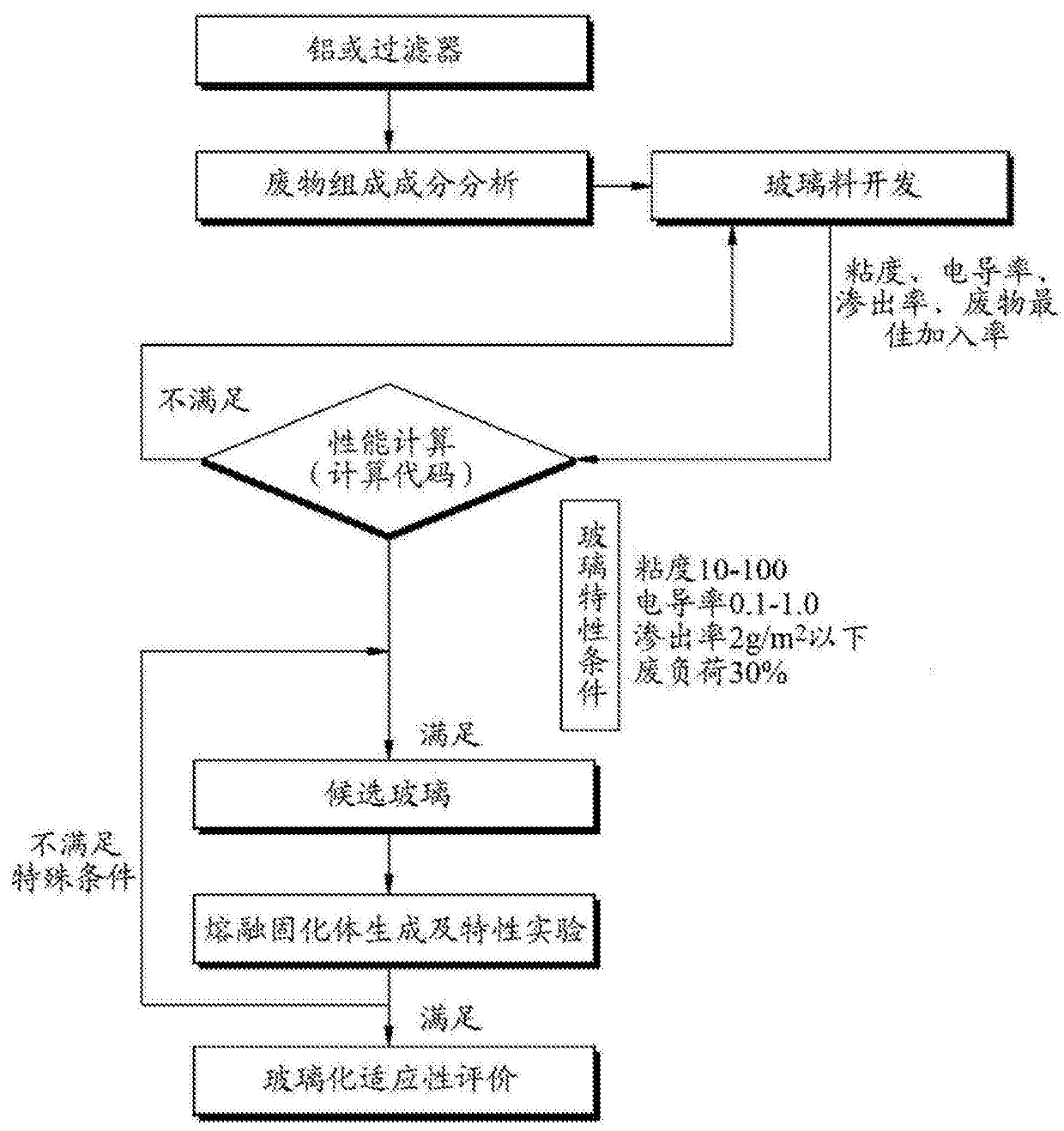

The object of the present invention is to provide such a vitrification treatment method of aluminum and filter radioactive waste: developing glass frit required for vitrification of aluminum and filter radioactive waste and proper mixing of aluminum and filter radioactive waste and glass frit , so as to develop the oxide composition distribution of aluminum and filter radioactive waste with a viscosity of 100 poise or less for maintaining the operating parameters of the furnace, thereby producing a high-quality vitrified body to solidify the vitrified glass as the final product of vitrification The body complies with relevant laws and regulations. In order to achieve the above object, the method of vitrification of aluminum and filter radioactive waste is characterized in that aluminum, filter radioactive waste and glass frit are mixed in an induction heating type low-temperature melting furnace, melted at 1100°C to 1200°C, and vitrified to form a glass solidified body.

Description

Vitrification method of aluminum and filter radioactive waste technical field The present invention relates to a vitrification treatment method of aluminum and filter radioactive waste, in particular to a vitrification treatment method of aluminum and filter radioactive waste as follows: developed in the air conditioning system (HVAC) of nuclear power plants and atomic furnace facilities Treatment of pollutants, glass frit required for vitrification of aluminum and filter radioactive waste generated using CCIM, derivation of aluminum and filtration for mixing with glass frit for maintaining suitable melt viscosity The amount of radioactive waste added to the glass can be used to deduce the oxide composition range of the formed aluminum and filter radioactive waste, thereby trapping the pollutants in the glass structure and preventing the aluminum and filter radioactive waste from being discharged to the outside. Background technique Typically, low and intermediate level ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03C3/066C03C3/093

Inventor 赵贤济金荣一赵现俊金千雨

Owner KOREA HYDRO & NUCLEAR POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com