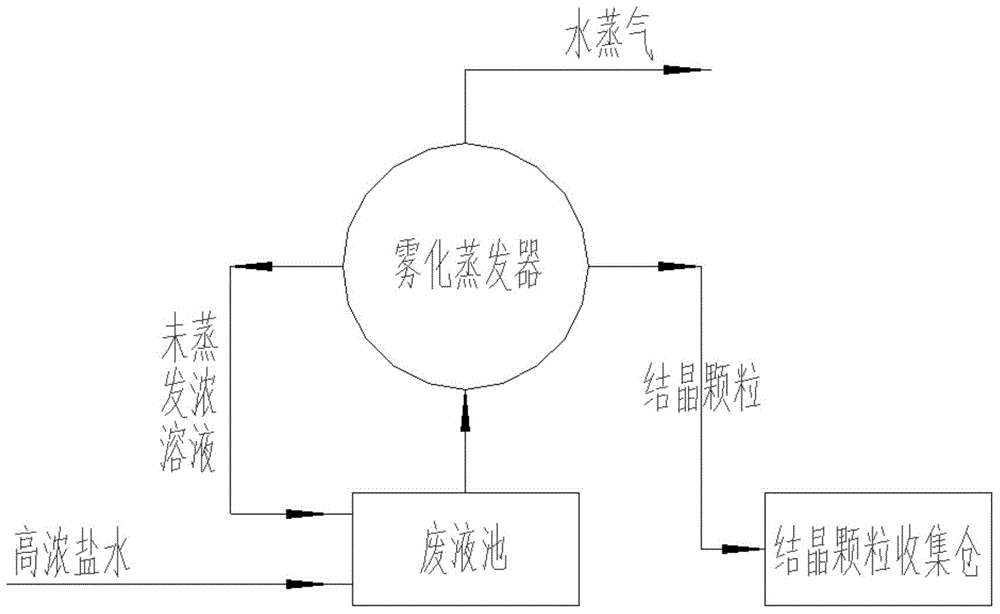

Multiple-effect coupled atomization evaporator

A technology of atomization evaporation and atomization device, which is applied in the field of atomization evaporators, can solve the problems of high processing cost, low long-term efficiency, high land cost, etc., and achieve the goal of strengthening evaporation crystallization process, reducing floor space and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] As shown in the drawings, the present invention is a multi-effect coupling atomizing evaporator, the main body of the atomizing evaporator is a tower tube 3 with an open lower bottom, and a waste liquid pool for storing waste concentrated brine is arranged under the tower tube 3 6. The tower 3 is supported by the support base 10 arranged in the circumferential direction under the tower 3 so as to leave an air inlet between the waste liquid pool 6 and an air inlet adjustment baffle 12 arranged circumferentially outside the tower 3 , by moving the air intake adjustment baffle 12 up and down to adjust the air intake area and thereby adjust the evaporation air volume; the thermal fluid inlet pipe 1 communicates with the tower tube 3 through one or more thermal fluid equalization chambers 13 in the tower tube, forming Single-point delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com