Environment-friendly preparation method of nano manganese oxide composite material

A composite material, manganese oxide technology, applied in manganese oxide/manganese hydroxide, nanotechnology, nanotechnology and other directions, can solve the problems of difficult industrialized production, difficult to achieve mass production, slow reduction speed, etc., and achieve industrialized production. , the preparation time is short, the effect of expanding the scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, in the mixed solvent of 50% volume ratio isopropanol and water, do not add conductive material, do not adjust pH value, utilize this method to prepare nano manganese oxide as embodiment:

[0032] Step 1: Dissolve 500 mg of potassium permanganate in 40 ml of deionized water;

[0033] Step 2: Add 250 ml of isopropanol to 250 ml of deionized water and mix well;

[0034] Step 3: Slowly add the potassium permanganate solution dropwise into the mixed organic solution at a stirring speed of 300 rpm;

[0035] Step 4: After reacting at normal temperature for about 1 hour, use an organic filter membrane with a pore size of 0.45 micron to filter, wash repeatedly for 3 times, and prepare nano-manganese oxide powder after drying.

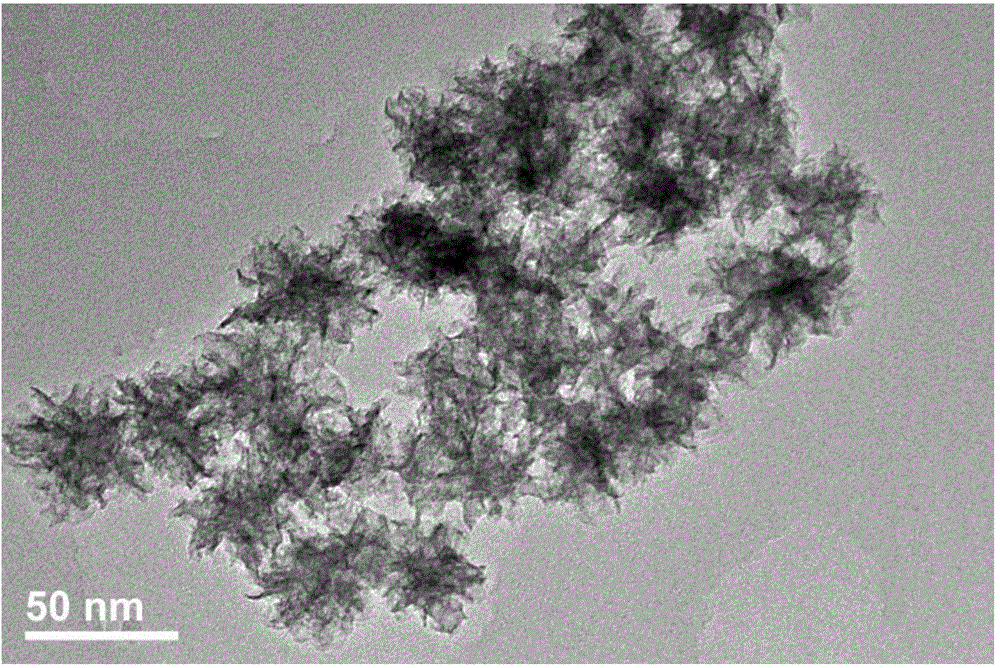

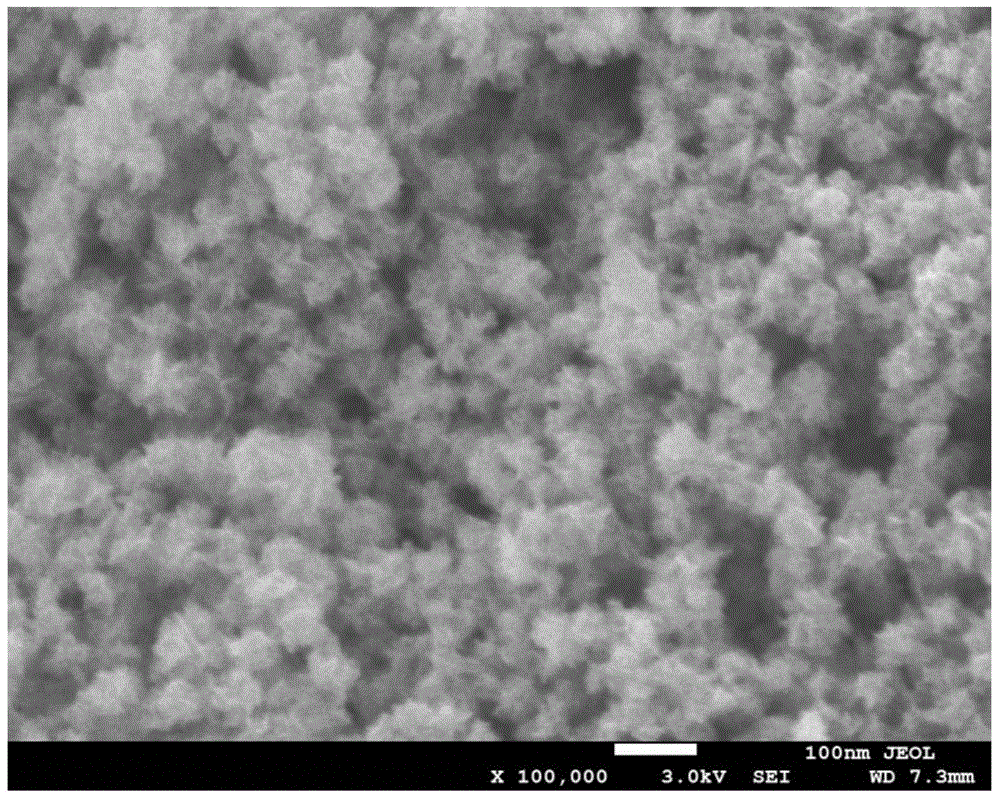

[0036] The obtained nano-flower-like manganese oxide TEM photographs are as follows: figure 1 As shown, the scanning electron microscope photo is shown as figure 2 shown.

Embodiment 2

[0037] Embodiment 2, in the mixed solvent of 30% volume ratio ethanol and water, do not add conductive material, pH is about 1, utilize this method to prepare nano manganese oxide as embodiment:

[0038] Step 1: Dissolve 300 mg of potassium permanganate in 30 ml of deionized water;

[0039] Step 2: Add 150 ml of ethanol to 350 ml of deionized water and mix well;

[0040] Step 3: At a stirring speed of 500 rpm, add hydrochloric acid solution dropwise to adjust the pH value to 1, and then slowly add potassium permanganate solution dropwise into the mixed organic solution;

[0041] Step 4: After reacting at normal temperature for about 1 hour, use an organic filter membrane with a pore size of 0.45 micron to filter, wash repeatedly for 3 times, and prepare nano-manganese oxide powder after drying.

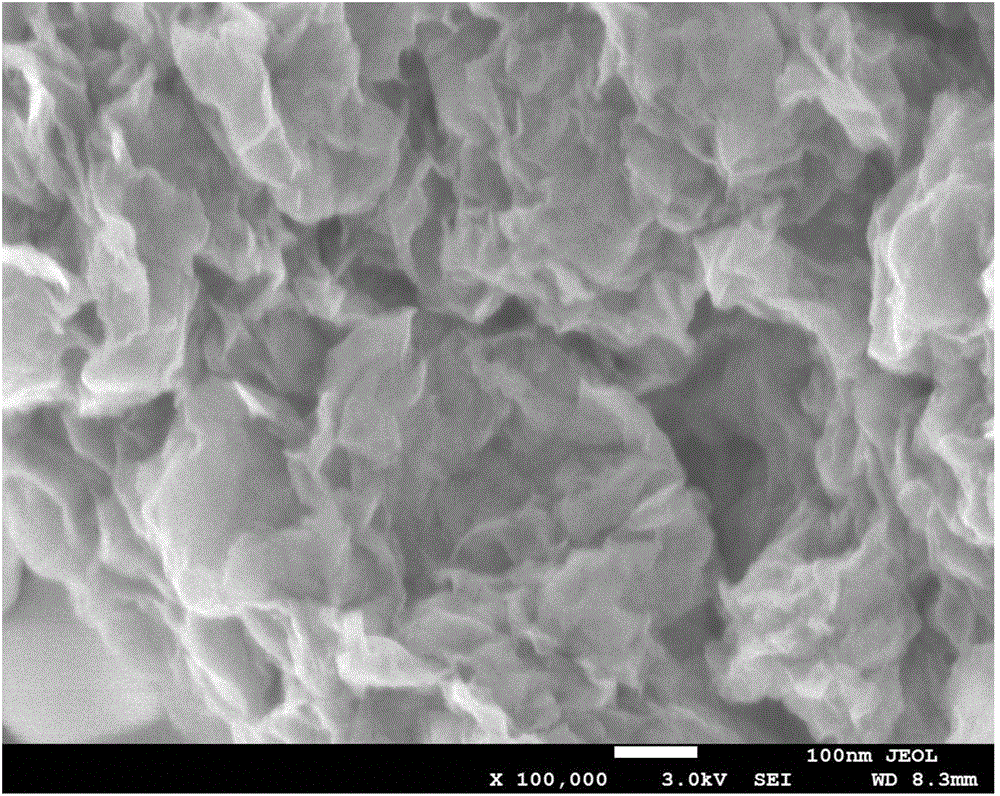

[0042] The obtained scanning electron micrographs of wrinkled manganese oxide are as follows: image 3 shown.

Embodiment 3

[0043] Embodiment 3, in the mixed solvent of 60% volume ratio methanol and water, do not add conductive material, pH is about 13, utilize this method to prepare nano manganese oxide as embodiment:

[0044] Step 1: Dissolve 400 mg of potassium permanganate in 30 ml of deionized water;

[0045] Step 2: Add 300 ml of methanol to 200 ml of deionized water and mix well;

[0046] Step 3: Add sodium hydroxide solution dropwise to adjust the pH value to 13 at a stirring speed of 600 rpm, and then slowly add potassium permanganate solution dropwise into the mixed organic solution;

[0047] Step 4: After reacting at normal temperature for about 0.5 hours, use an organic filter membrane with a pore size of 0.45 micron to filter, wash repeatedly for 3 times, and prepare nano-manganese oxide powder after drying.

[0048] The obtained scanning electron micrographs of spherical manganese oxide are as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com