Photonic crystal-based environment-friendly refrigeration sticker for buildings

A technology of photonic crystals and buildings, applied in the direction of building structure, construction, layered products, etc., can solve the problems of ineffectiveness, limited application range, neglect of visible light transmittance, etc., and achieve the effect of widening the photonic band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

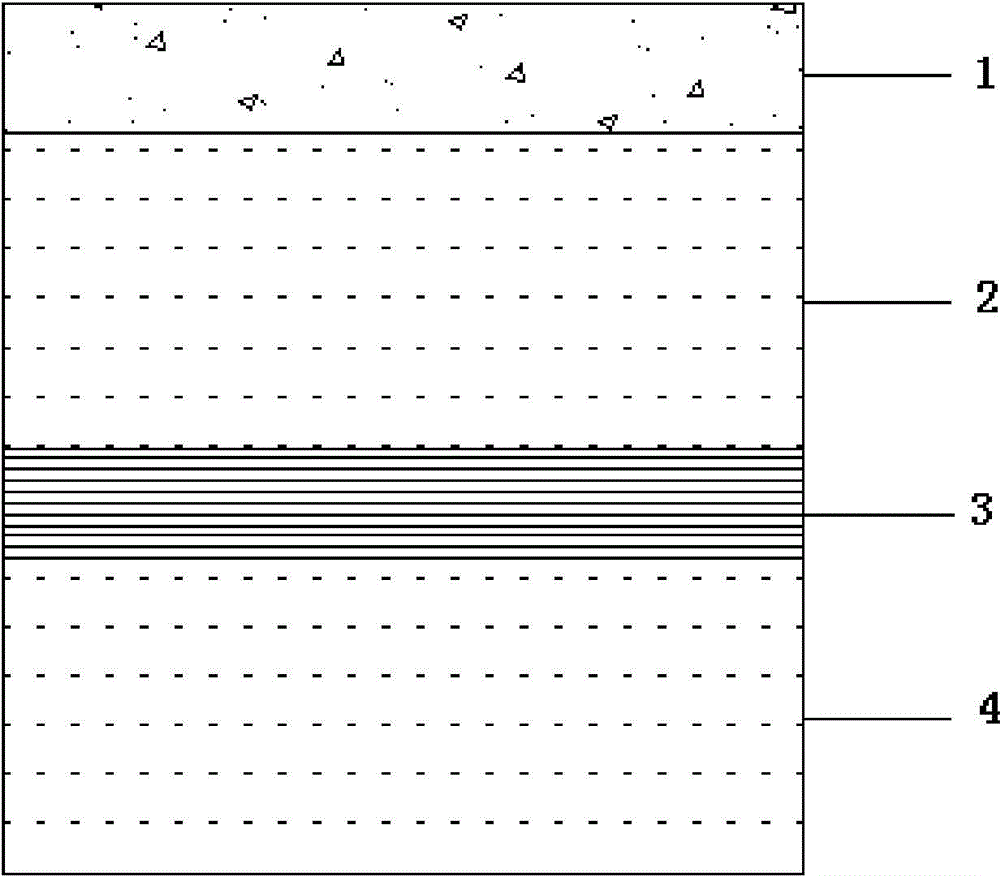

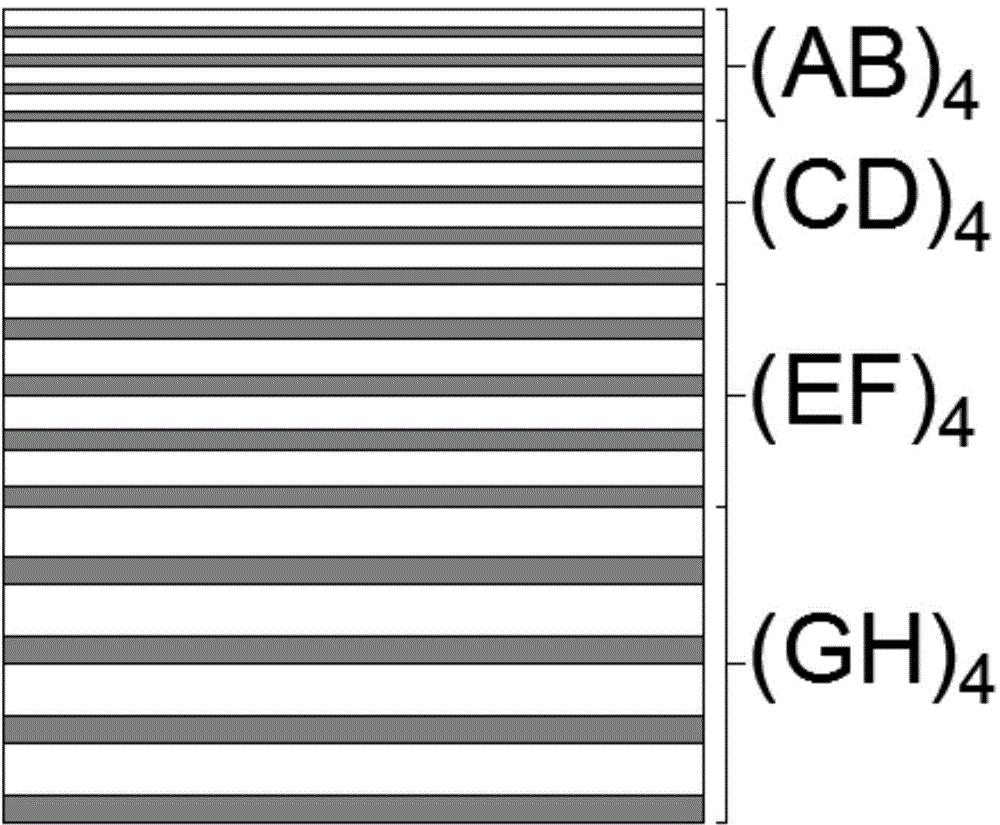

[0035] Such as Figure 1-2As shown, an environmentally friendly cooling film for buildings based on photonic crystals, the cooling film includes a scratch-resistant and wear-resistant layer 1, an upper substrate layer 2, a photonic crystal cooling layer 3 and a lower substrate layer 4 from top to bottom, The anti-scratch and wear-resistant layer 1 is a polyurethane anti-scratch and wear-resistant layer, the upper substrate layer 2 and the lower substrate layer 4 are both polyethylene terephthalate substrate layers, and the photonic crystal cooling layer 3 is composed of the first composite layer , the second composite layer, the third composite layer and the fourth composite layer are stacked sequentially from top to bottom, and the structural formula is (AB) 4 (CD) 4 (EF) 4 (GH) 4 , the first composite layer is composed of 4 layers of A dielectric layer and 4 layers of B dielectric layer alternately superimposed on each other (AB) 4 Type composite structure, the second co...

Embodiment 2

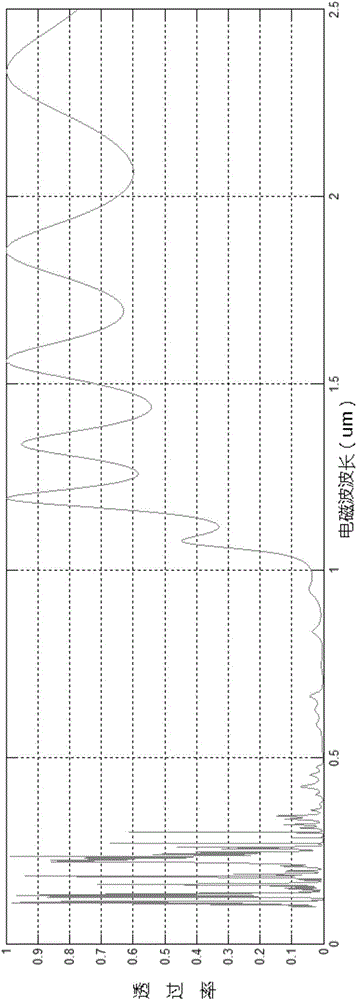

[0042] In this embodiment, the total thickness of the photonic crystal cooling layer 3 is 2.352 μm, the refractive index of the silicon dioxide dielectric layer is 1.45, the titanium dioxide is anatase titanium dioxide, and the refractive index of the anatase titanium dioxide is 2.65.

[0043] The thickness of the A dielectric layer in the first composite layer is 52nm, the thickness of the B dielectric layer is 29nm; the thickness of the C dielectric layer in the second composite layer is 76nm, and the thickness of the D dielectric layer is 42nm; the E dielectric layer in the third composite layer The thickness of the F medium layer is 104nm, the thickness of the F medium layer is 57nm; the thickness of the G medium layer in the fourth composite layer is 147nm, and the thickness of the H medium layer is 81nm; the thickness of the scratch-resistant and wear-resistant layer 1 is 4μm; the upper substrate layer 2 It is equal to the thickness of the lower substrate layer 4, and the...

Embodiment 3

[0045] In this embodiment, the total thickness of the photonic crystal cooling layer 3 is 2.336 μm, the refractive index of the silicon dioxide dielectric layer is 1.45, the titanium dioxide is anatase titanium dioxide, and the refractive index of the anatase titanium dioxide is 2.65.

[0046] The thickness of the A dielectric layer in the first composite layer is 51.5nm, the thickness of the B dielectric layer is 28.5nm; the thickness of the C dielectric layer in the second composite layer is 75.5nm, and the thickness of the D dielectric layer is 41.5nm; the third composite layer The thickness of the medium E medium layer is 103.5nm, the thickness of the F medium layer is 56.5nm; the thickness of the G medium layer in the fourth composite layer is 146.5nm, and the thickness of the H medium layer is 80.5nm; the thickness of the scratch-resistant and wear-resistant layer 1 is 3 μm; the thickness of the upper substrate layer 2 and the lower substrate layer 4 are equal, and the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com