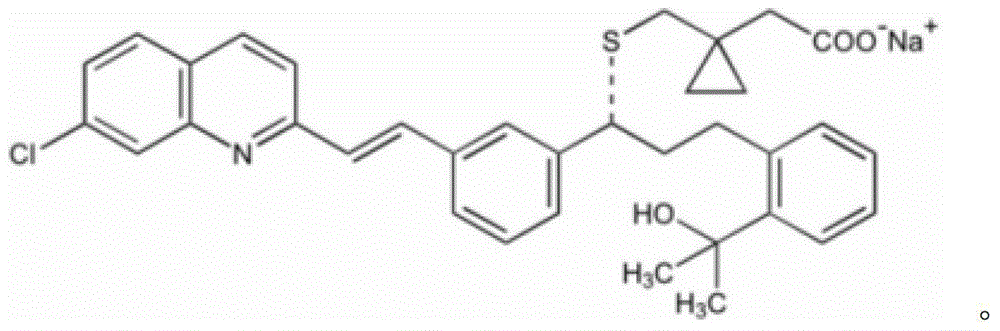

Solid oral preparation containing montelukast and preparation method of solid oral preparation

A technology of montelukast sodium and oral preparations, which is applied in the field of solid oral preparations containing montelukast sodium and its preparation, and can solve the problem of poor wet stability and the inability to fundamentally solve the stability of montelukast sodium, Sensitivity and other issues, to achieve the effect of improving stability, using less excipients, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Montelukast Sodium 10g

[0029] 100g pregelatinized starch

[0030] Sucrose Fatty Acid Ester 4g

[0031] Preparation Process:

[0032] Grind montelukast sodium through an 80-mesh sieve, and set aside; dry the pregelatinized starch at 105°C, airtightly let it cool, and set aside; weigh the amount of montelukast sodium, pregelatinized starch, and sucrose fatty acid ester and mix evenly , Φ6.5mm shallow arc stamping sheet, that is. After testing, the initial moisture content of the tablet was 0.91%.

Embodiment 2

[0034] Montelukast Sodium 10g

[0035] 200g pregelatinized starch

[0036] Sucrose Fatty Acid Ester 11g

[0037] Preparation Process:

[0038]Grind montelukast sodium through an 80-mesh sieve, and set aside; dry the pregelatinized starch at 105°C, airtightly let it cool, and set aside; weigh the amount of montelukast sodium, pregelatinized starch, and sucrose fatty acid ester and mix evenly , Φ9mm shallow arc stamping sheet, that is. After testing, the initial moisture content of the tablet was 0.42%.

Embodiment 3

[0040] Montelukast Sodium 10g

[0041] 300g pregelatinized starch

[0042] Sucrose Fatty Acid Ester 20g

[0043] Preparation Process:

[0044] Grind montelukast sodium through an 80-mesh sieve, and set aside; dry the pregelatinized starch at 105°C, airtightly let it cool, and set aside; weigh the amount of montelukast sodium, pregelatinized starch, and sucrose fatty acid ester and mix evenly , Φ10mm shallow arc stamping sheet, that is. After testing, the initial moisture content of the tablet was 0.59%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com