Comprehensive failure diagnostic system for triphase controllable thyristor rectifier

A technology of fault diagnosis system and rectification device, which is applied in the field of comprehensive fault diagnosis system, can solve problems such as difficulty in protection and maintenance work, economic loss, and various types of rectification device faults, and achieve good diagnostic accuracy, good applicability, and readability High performance and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

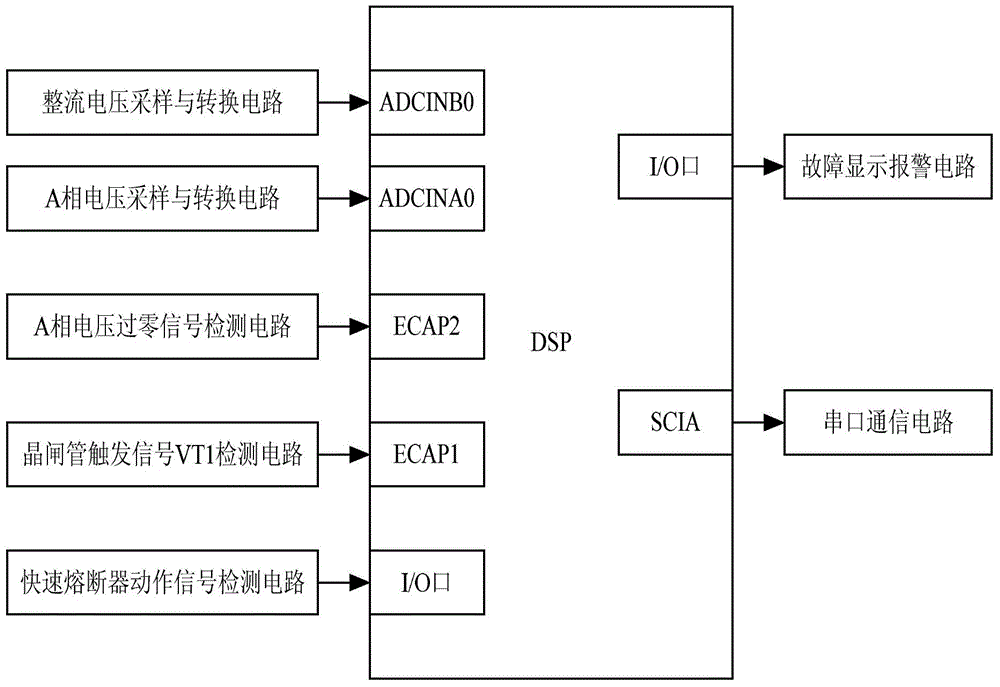

[0023] A comprehensive fault diagnosis system for a three-phase controllable thyristor rectifier, which consists of circuits such as rectification voltage sampling, AC input voltage sampling, synchronous signal capture, protection signal detection, fault display and alarm, and communication with an upper computer.

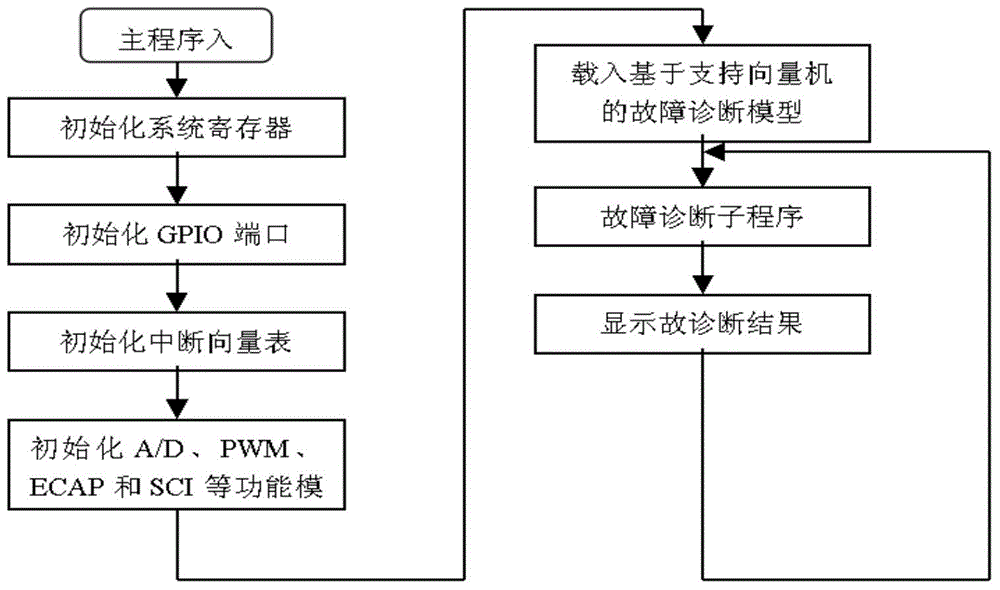

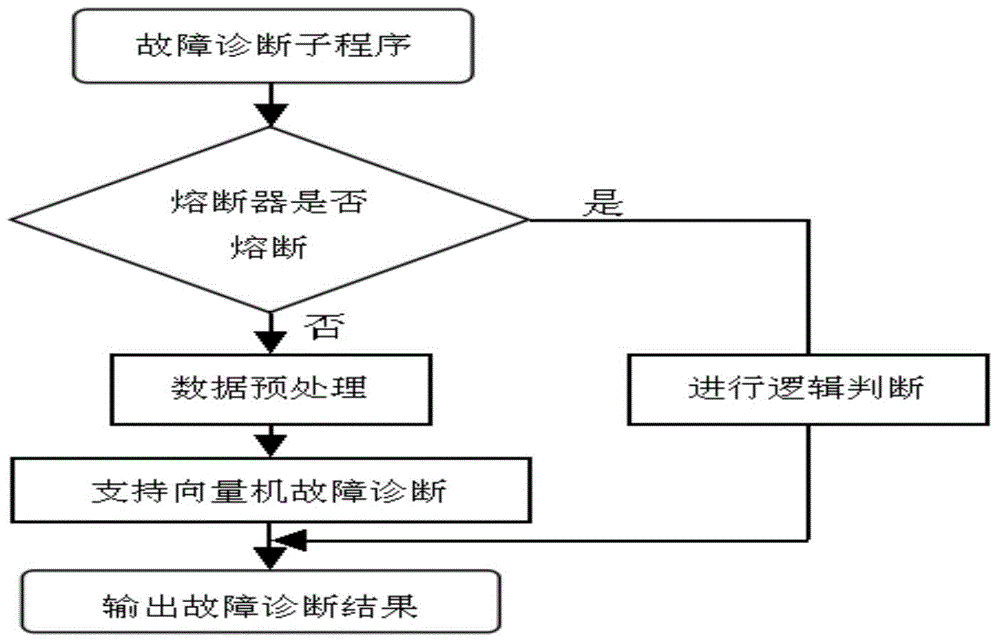

[0024] It is characterized in that the software of the fault diagnosis system of the rectification device adopts modular programming, and according to the different functions completed by the fault diagnosis system, the programs for performing different functions are divided into different subroutine modules.

[0025] It is characterized in that: the subroutine module specifically includes a system initialization subroutine module, a voltage zero-crossing time capture subroutine module, a voltage zero-crossing time capture subroutine module, a thyristor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com