PTC thermistor alloy wire and preparation method thereof

A thermistor and alloy wire technology, applied in the field of alloy wire, can solve the problems of not forming a series of products and a single variety, and achieve the effect of avoiding sulfur corrosion and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (Example 1, PTC thermistor alloy wire)

[0036] The chemical composition of the alloy wire of the PTC thermistor of this embodiment in terms of weight percentages are: nickel (Ni) 78.0%, silicon (Si) 0.6%, manganese (Mn) 0.3%, and yttrium (Y) 0.02%~0.04%. (0.03% in this embodiment), mixed rare earth 0.04% to 0.06% (0.05% in this embodiment), carbon (C) less than or equal to 0.05%, sulfur (S) less than or equal to 0.01%, phosphorus (P) less than Equal to 0.001%, and the balance is iron (Fe).

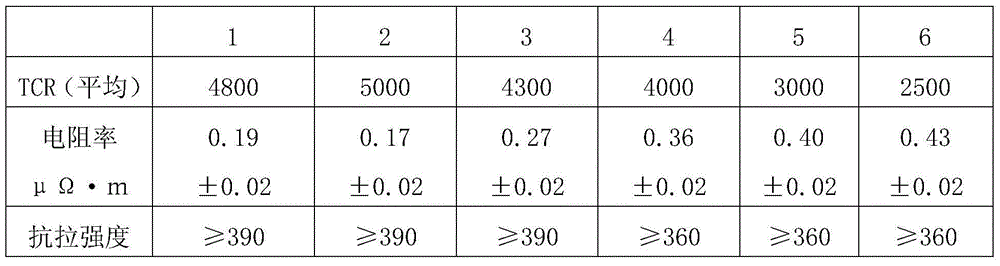

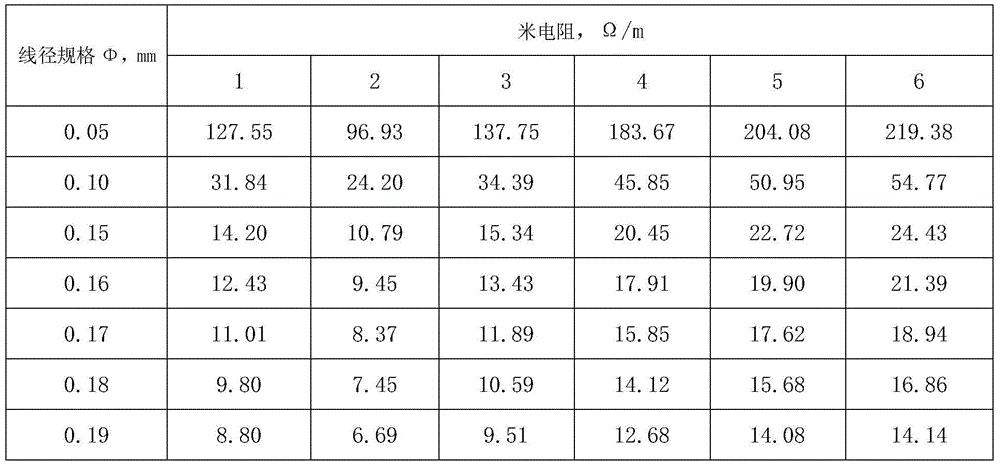

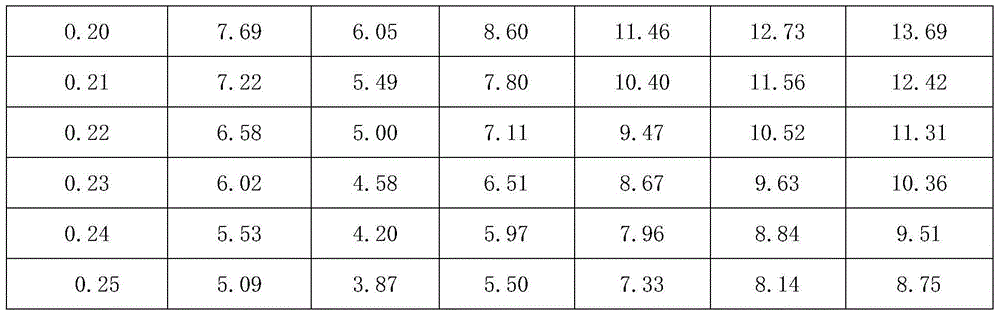

[0037] The average temperature coefficient of resistance of the PTC thermistor alloy wire of this embodiment from 0°C to 150°C is 4800×10 -6 / ℃; The accuracy of the resistance temperature coefficient is ±50×10 -6 / ℃; the resistivity of the alloy wire at 20℃ is (0.19±0.02)μΩ·m. The tensile strength of the soft alloy wire is greater than 390Mpa.

[0038] Since the emerging electrical equipment requires more sensitive temperature control and adjustment resistance elements, the upper limit ...

Embodiment 2 to Embodiment 6

[0056] (Example 2 to Example 6, PTC thermistor alloy wire)

[0057] The chemical composition of the PTC thermistor alloy wires of Example 2 to Example 6 are shown in Table 3 in terms of weight percentage:

[0058] Table 3 Example 1 to Example 6

[0059]

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Nickel (Ni)

78.0%

82%

64.45%

53%

49%

45%

Silicon (Si)

0.6%

0.28

0.1

0.1

0.25

0.25

Manganese (Mn)

0.3%

0.35

0.22

0.22

0.35

0.35

Yttrium (Y)

0.03%

0.03

0.03

0.03

0.03

0.03

Mixed rare earth

0.05%

0.05

0.05

0.05

0.05

0.05

Aluminum (Al)

--

--

--

--

0.45

0.45

Carbon (C)

≤0.05%

≤0.05%

≤0.05%

≤0.05%

≤0.05%

≤0.05%

[0060] Sulfur (S)

≤0.01%

≤0.01%

≤0.01%

≤0.01%

≤0.01%

≤0.01%

Phosphorus (P)

≤0.001%

≤0.001%

≤0.001%

≤0.001%

≤0.001%

≤0.001%

Iron (Fe)

Margin

Margin

Margin

Margin

Margin

Margin

[0061] The alloy wires of Examples 1 to 6 were observed with the naked eye: there was no joint, and the surface was smooth, smooth, and flat, without burrs an...

Embodiment 7

[0075] (Embodiment 7, Preparation method of PTC thermistor alloy wire)

[0076] The preparation method of the PTC thermistor alloy wire of this embodiment specifically includes the following steps:

[0077] ① Preparation of raw materials: Nickel is the standard of GB6516 No. 1 electrolytic nickel Ni-1; silicon is the standard of GB2881 first grade crystalline silicon Si-1; manganese is the standard of GB3418 electrolytic manganese DJMn99.5; yttrium is the standard of Q The rare earth metal Y-3 of / HUAC23; the mischmetal is the mischmetal RECE-45 with the standard of GB / T4153; iron is the raw material pure iron DT3 with the standard of GB / T9971;

[0078] ②Vacuum melting:

[0079] The equipment used for vacuum melting is the EG-25 vacuum induction furnace intermediate frequency machine equipment produced by Shanghai Electric Furnace Factory, of which:

[0080] a. The motor power of the variable frequency unit is 60 kW, the motor is three-phase, the generator voltage is 375 / 750 volts, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com