Method for preparation of composite material by embedding nanoparticles into perovskite nanowire

A technology of nanoparticles, composite materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

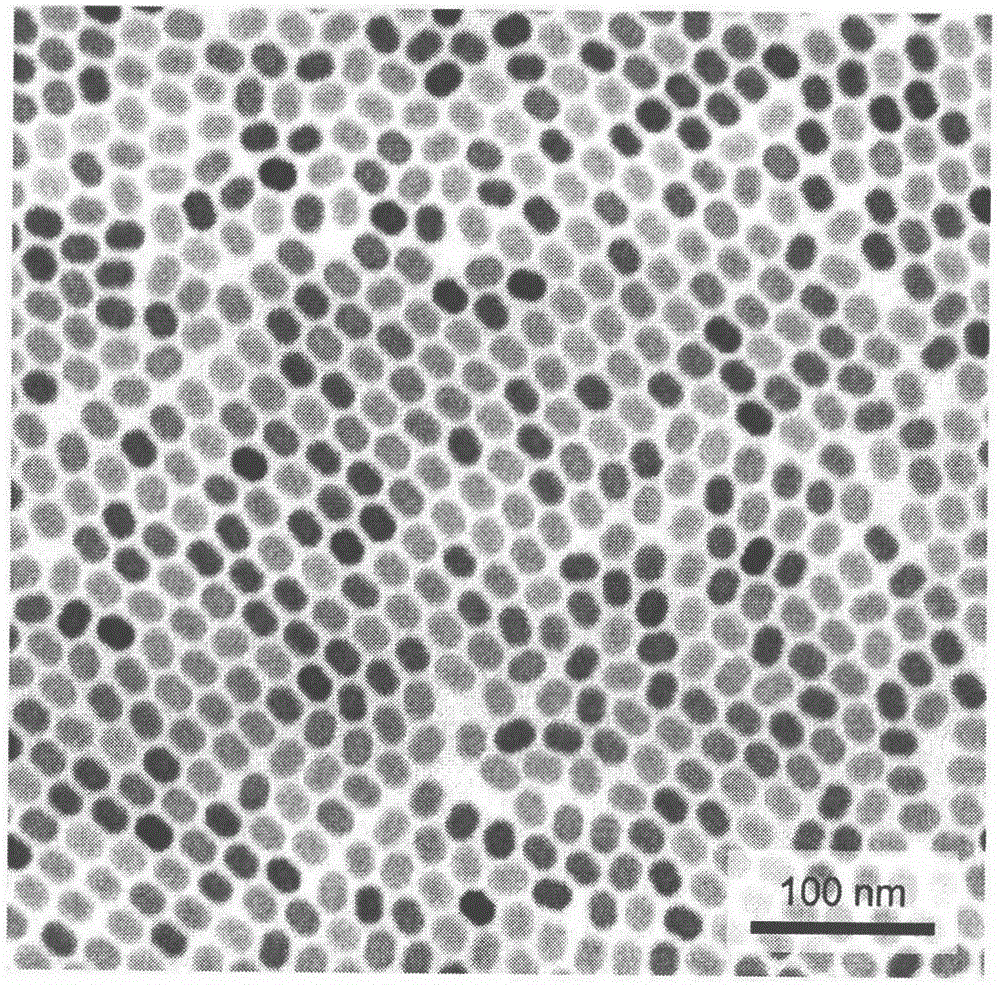

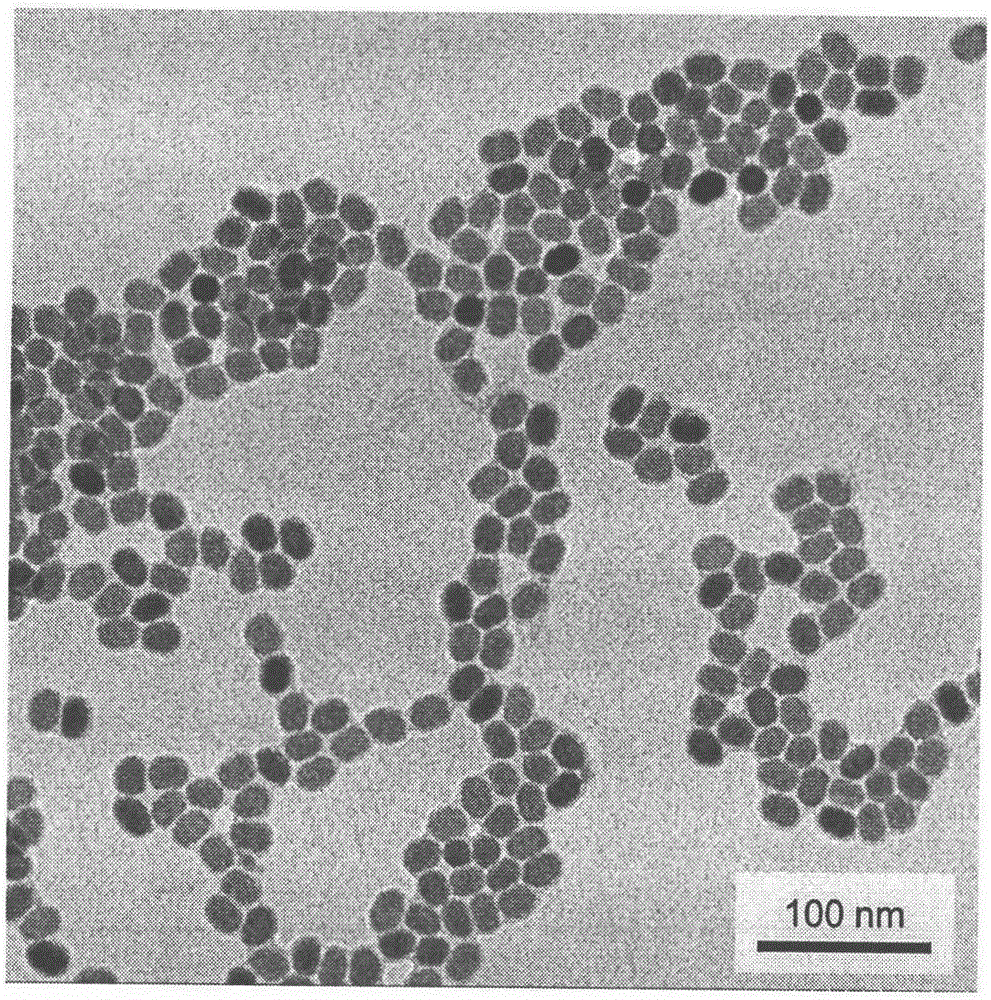

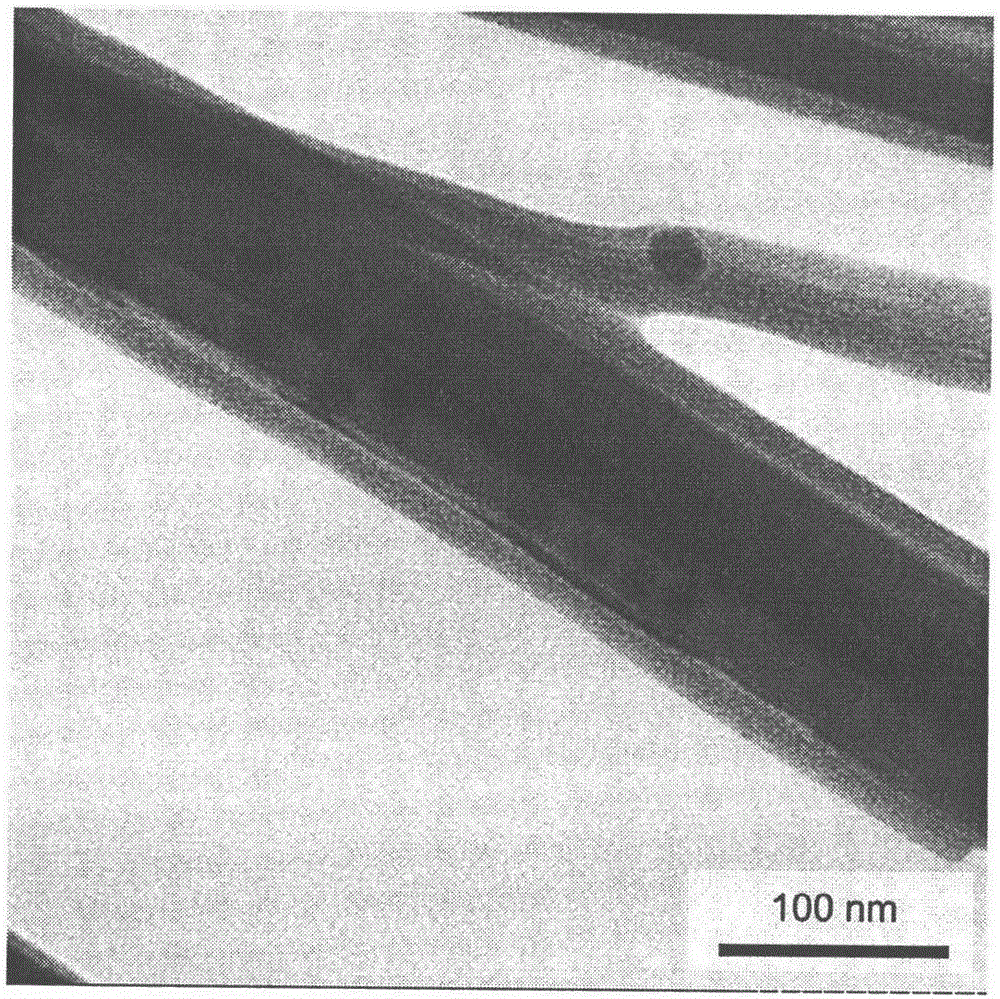

[0016] Accurately weigh 50mg polyethylene glycol and dissolve it in 15mL chloroform, then add 30mL chloroform solution dispersed with 5mg of 23nm nanoparticles in this solution, stir at room temperature for 24h; add cyclohexane and centrifuge to obtain the surface of polyethylene glycol For modified nanoparticles, disperse the nanoparticles in 20 mL of deionized water with 12 mg (0.1 mmol) of cysteine molecules dissolved, and then add 1 mL of 0.1 M lead acetate trihydrate deionized water solution to this solution. The reaction system Produce a large number of nano-particles embedded in organic / inorganic hybrid perovskite precursor nanowires, centrifuge to obtain a white solid, and then disperse the product in 10 mL of isopropanol solution. Finally, take 1 mL of isopropanol dispersion of precursor nanowires, and quickly add 30 mL of isopropanol solution with 0.5 g of iodomethylamine and 50 uL of hydroiodic acid under vigorous stirring, react at room temperature for 2 hours, and...

Embodiment 2

[0018] Accurately weigh 50mg of polyvinylpyrrolidone and dissolve it in 15mL of chloroform, then add 30mL of chloroform solution dispersed with 5mg of 2 nanometer nanoparticles in this solution, stir at room temperature for 24h; add cyclohexane and centrifuge to obtain polyvinylpyrrolidone surface-modified Nanoparticles, disperse the nanoparticles in 20mL of deionized water with 6mg (0.05mmol) of cysteine molecules dissolved, and then add 10mL of 0.1M lead chloride deionized water solution to this solution, the reaction system produces a lot of The organic / inorganic hybrid perovskite precursor nanowires embedded with nanoparticles were centrifuged to obtain a white solid, and then the product was dispersed in 10 mL of isopropanol solution. Finally, take 1 mL of isopropanol dispersion of precursor nanowires, and quickly add 30 mL of isopropanol solution with 0.5 g of iodomethylamine and 50 uL of hydrobromic acid under vigorous stirring, react at room temperature for 2 hours, an...

Embodiment 3

[0020] Accurately weigh 50mg of polyethyleneimine and dissolve it in 15mL of chloroform, then add 30mL of chloroform solution dispersed with 5mg of 23nm nanoparticles in this solution, stir at room temperature for 24h; add cyclohexane and centrifuge to obtain the surface of polyethyleneimine The modified nanoparticles were dispersed in 20 mL of deionized water with 12 mg (0.1 mmol) of cysteine molecules dissolved, and then 1 mL of 0.1 M lead nitrate deionized water solution was added to the solution, and the reaction system produced The organic / inorganic hybrid perovskite precursor nanowire embedded with a large number of nanoparticles was centrifuged to obtain a white solid, and then the product was dispersed in 10 mL of isopropanol solution. Finally, take 1 mL of isopropanol dispersion of precursor nanowires, and quickly add 30 mL of isopropanol solution with 0.5 g of iodomethylamine and 50 uL of hydroiodic acid under vigorous stirring, react at room temperature for 2 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com