Method and device for continuous carbonization and distillation to produce beta-naphthol with solvent method

A solvent method and solvent technology, applied in the field of continuous carbonization and rectification production of β-naphthol by solvent method, can solve the problems of large amount of high-salt organic wastewater, unstable product quality, corrosion of equipment and pipelines, etc., and achieve equipment volume and quantity reduction, eradication of high-salt organic wastewater, and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

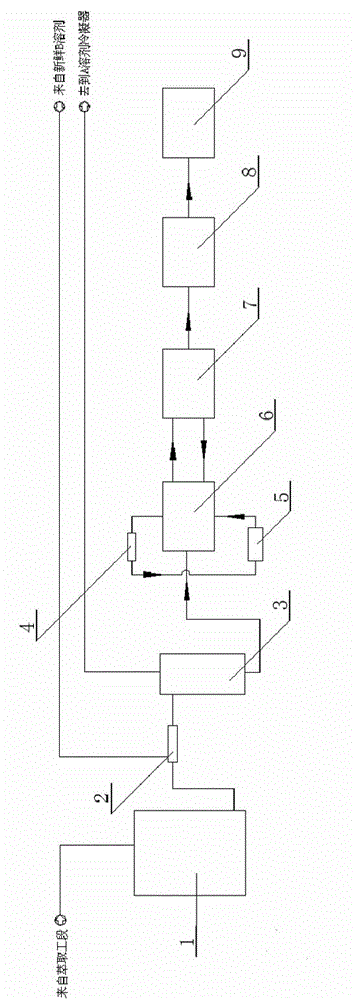

Image

Examples

Embodiment 1

[0039] Add hydrogenated terphenyl and β-naphthol sodium into the ethanol extraction concentrate from the extraction section in a mass ratio of 1.5:1 for mixing; after mixing evenly, enter the de-A rectification tower to remove ethanol solvent; remove ethanol The solvent material enters the carbonization reactor with CO 2 Reaction, the reacted material enters the β-naphthol crude product distillation tower to remove the β-naphthol crude product, and then enters the carbonization reactor and CO 2 Reaction: The content of 2,3-acid disodium salt in the tower bottom material after the pressure is 0.7MPa and continuous carbonization for 8 hours is 82.8%. The content of β-naphthol is 0.52% based on the β-naphthol sodium participating in the reaction.

Embodiment 2

[0041] Add hydrogenated terphenyl and β-naphthol sodium into the ethylene glycol extraction concentrate from the extraction section at a mass ratio of 1.5:1 for mixing; after mixing evenly, enter the de-A rectification tower to remove the ethylene glycol solvent ; The material after removing the ethylene glycol solvent enters the carbonization reactor and CO 2 Reaction, the reacted material enters the β-naphthol crude product distillation tower to remove the β-naphthol crude product, and then enters the carbonization reactor and CO 2Reaction: The content of 2,3-acid disodium salt in the tower bottom material after continuous carbonization for 10 hours at a pressure of 0.7MPa is 87.1%. The content of β-naphthol is 0.61% based on the β-naphthol sodium participating in the reaction.

Embodiment 3

[0043] Mix 70% of 1-methyl-3-phenylindane with 20% of 12-alkylbenzene and add β-naphthol sodium in a mass ratio of 1.5:1 to the methanol extraction concentrate from the extraction section. mixed in the liquid; after mixing evenly, it enters the de-A rectification tower to remove the methanol solvent; the material de-methanol solvent enters the carbonization reactor and CO 2 Reaction, the reacted material enters the β-naphthol crude product distillation tower to remove the β-naphthol crude product, and then enters the carbonization reactor and CO 2 Reaction: The content of 2,3-acid disodium salt in the tower bottom material after continuous carbonization at 0.7 MPa for 8 hours is 84.3%, and the content of β-naphthol is 0.43% based on the β-naphthol sodium participating in the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com