Preparing methods of porous graphene and porous graphene film

A technology of porous graphene and graphene, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high cost, less performance research, and low yield, and achieve the benefit of materials performance, enhanced diffusion and migration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention provides a method for preparing porous graphene, wherein the method comprises: mixing graphene and / or graphene oxide with an etchant to obtain a mixture; and performing a carbothermal reaction on the mixture under oxygen-free conditions , and perform acid treatment to remove unreacted and reacted etchants; the etchants are one or more of metal oxo salts, metal hydroxides and metal oxides.

[0021] According to the method of the present invention, as long as graphene and / or graphene oxide is mixed with an etchant, a carbothermal reaction is carried out under oxygen-free conditions and an acid treatment is carried out to remove unreacted and reacted etchant Porous graphene can be obtained, the present invention has no special requirements on the consumption of graphene and / or graphene oxide and etchant, preferably, the quality of the graphene and / or graphene oxide and etchant When the ratio is 0.1-10:1, more preferably 0.5-2:1, porous graphene with a...

Embodiment 1

[0058] Preliminary Example 1 Preparation of ultrapure aqueous solutions of graphene oxide

[0059] At 20 °C, 2.0 g of flake graphite with a fineness of 325 mesh and 1.5 g of sodium nitrate were added to 80 mL of concentrated sulfuric acid (98% by weight), the resulting mixture was placed in a 500 mL beaker and cooled with a 0 °C ice-water bath 30min to a temperature of 8°C to obtain a suspension.

[0060] At 5°C, at a stirring speed of 700 rpm (size of stirring bar: 6 cm), 9.0 g of potassium permanganate was added to the above suspension (1.5 g every 15 minutes), and then the The ice-water bath was removed and kept for 120 hours, 150 mL of ultrapure water was added (once every 5 minutes, 50 mL each time), and half an hour later, 250 mL of 3 mass% hydrogen peroxide was added to obtain a bright yellow solution. Centrifuge and wash with ultrapure water until there is no sulfate ion in the bright yellow solution, then centrifuge the solution (2560×g, 3000rpm) to obtain 6mg / mL g...

Embodiment 11

[0109] (1) Preparation of a mixture of graphene oxide and sodium molybdate

[0110] The graphene oxide ultrapure aqueous solution (4 mg / mL, 50 mL) obtained in Preliminary Example 1 was mixed with the sodium molybdate ultrapure aqueous solution (0.02 mol / L, 50 mL). Shake in a shaker for 12 hours at 100 rpm. After freezing the mixed solution in a liquid nitrogen bath for 15 minutes, it was dried using a freeze dryer (48 hours, the temperature was -50 °C, and the pressure was 7.5 Pa) to prepare a mixture of graphene oxide and sodium molybdate.

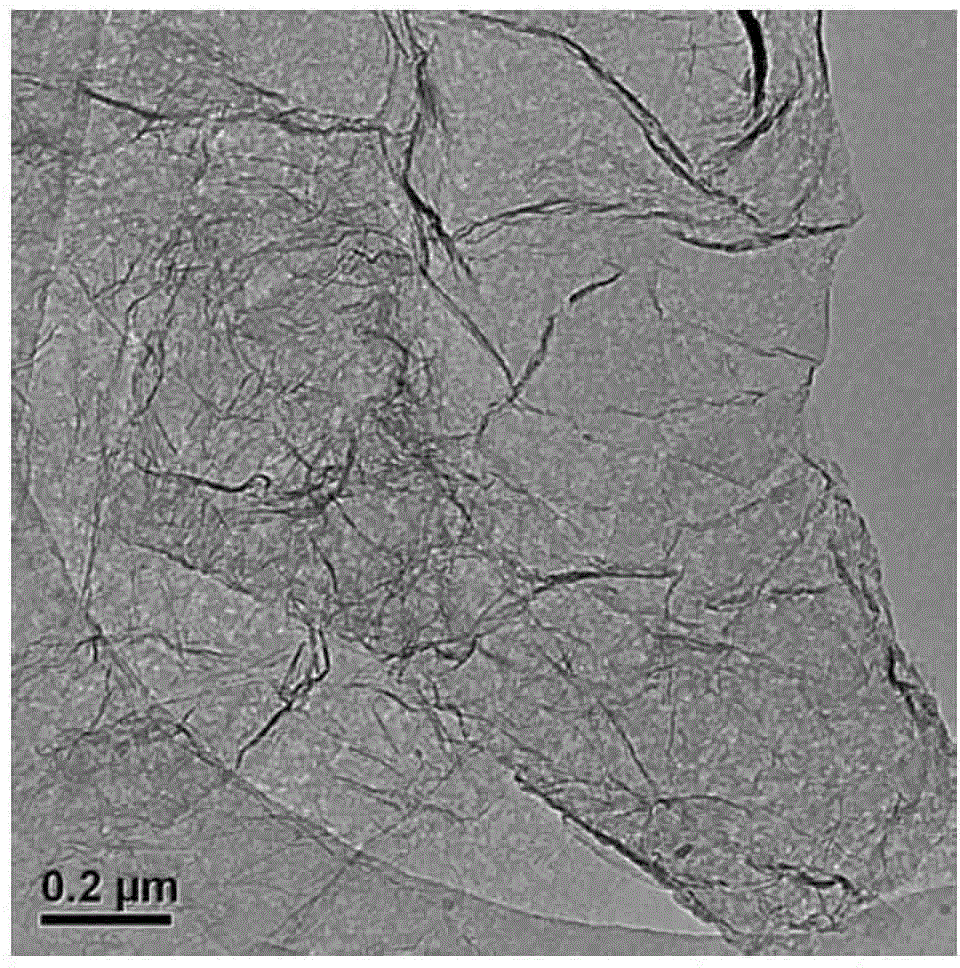

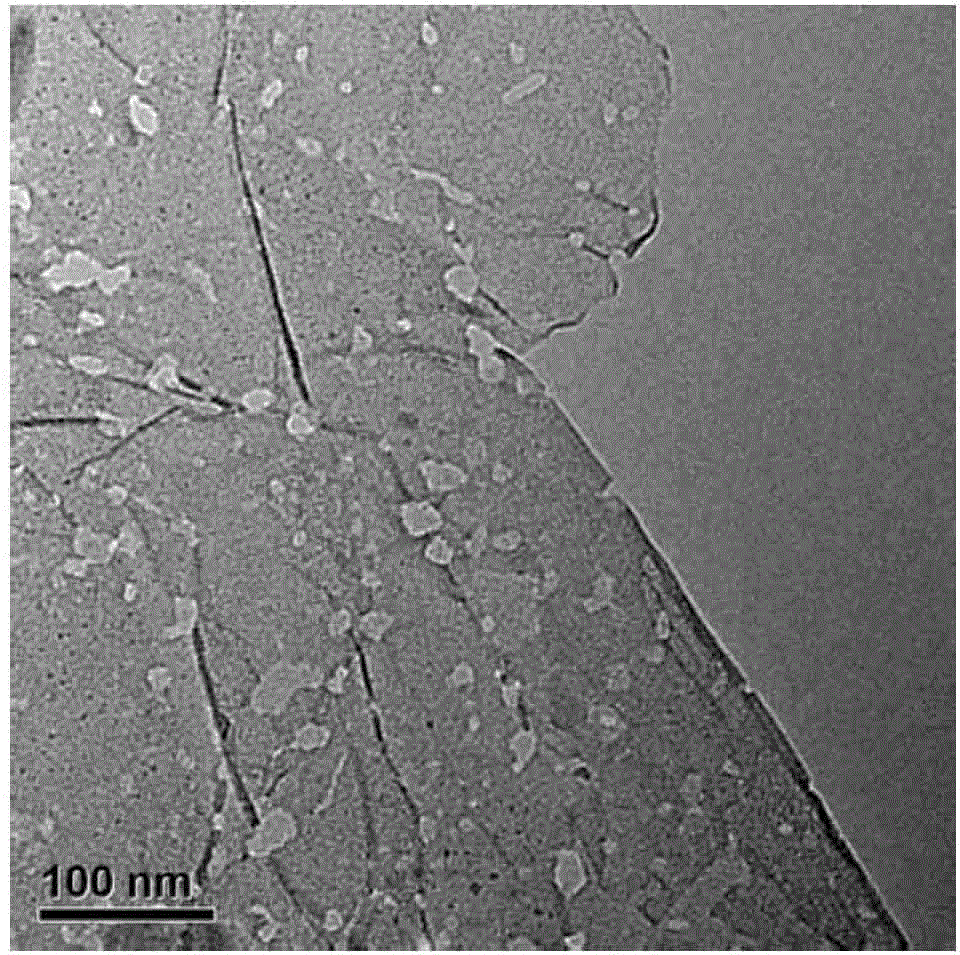

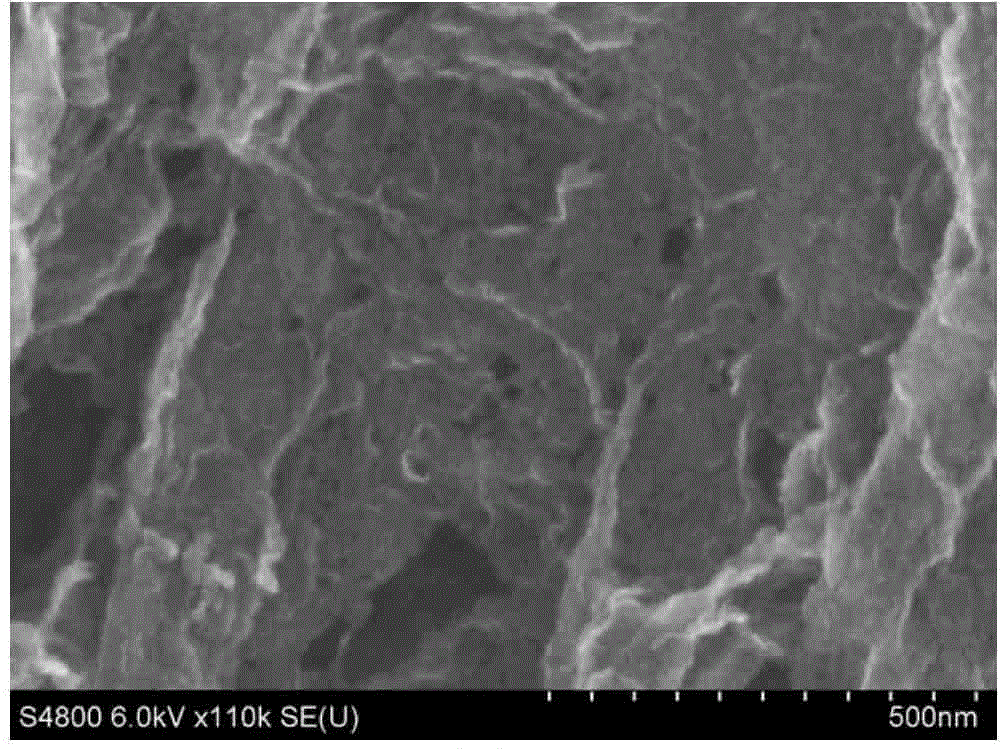

[0111] (2) Preparation of porous graphene

[0112]The mixture of graphene oxide and sodium molybdate obtained in step (1) was placed in a tube furnace as a precursor (200 mg), and under nitrogen protection, the temperature was raised to 650 ° C, and the heating rate was 10 ° C / min. Incubate for 120 minutes and naturally cool to room temperature. The obtained black solid was dispersed in dilute hydrochloric acid (0.5 mol / L, 50 mL), stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com