A Controllable Patterned Ultrafast Laser Composite Fabrication Method of Metal Oxide Nanowires

An ultrafast laser, oxide technology, applied in the preparation of oxide/hydroxide, oxygen/ozone/oxide/hydroxide, chemical instruments and methods, etc., can solve the problems of complex process and high cost, Achieve the effect of accelerating the growth process, improving support strength and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

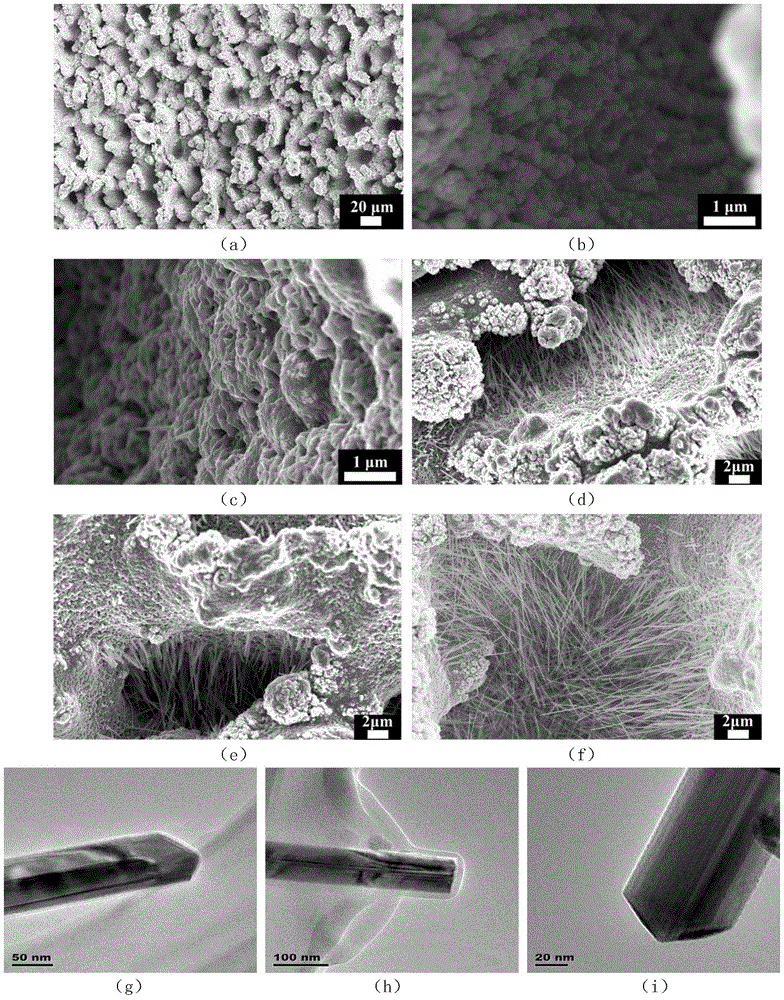

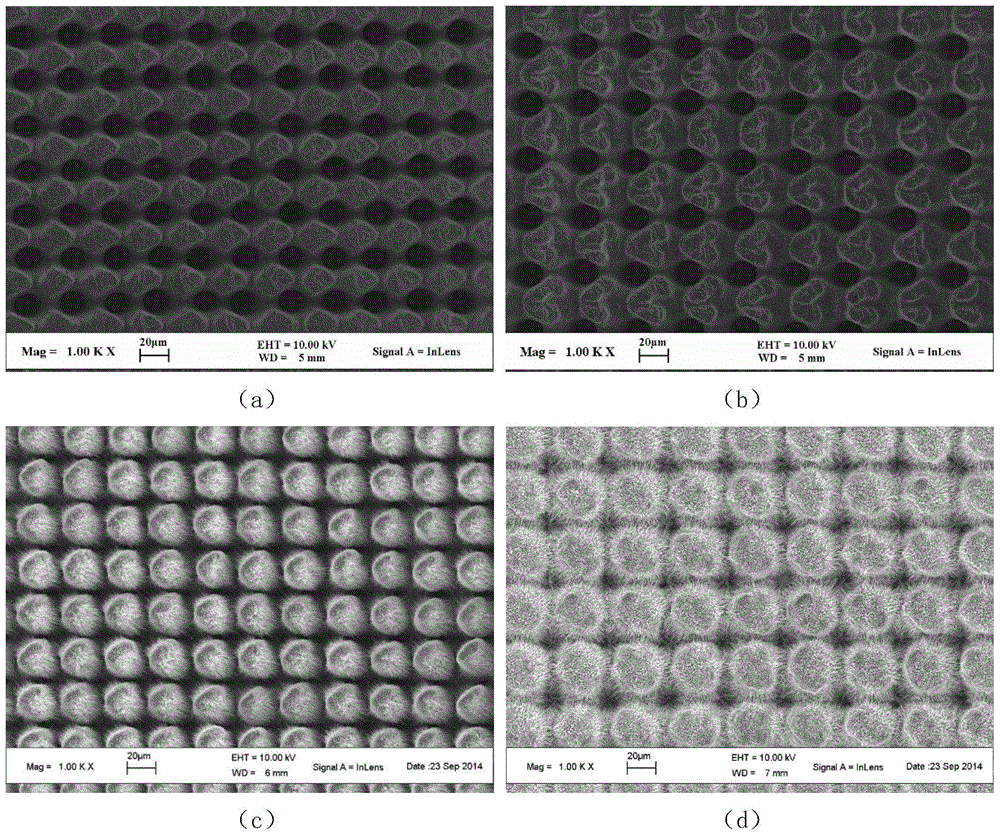

[0062] Example 1. Picosecond pulsed laser preparation of micro-nano precursor structure on Cu surface to realize patterned growth of CuO nanowires

[0063] The controllable patterning preparation of CuO nanowires in this embodiment includes the following steps:

[0064] (1) Remove the oxide layer on the surface of the bulk Cu by mechanical grinding, and make the surface reach a certain degree of smoothness, then clean the Cu surface with alcohol, and blow or dry the surface of the Cu block after cleaning.

[0065] (2) Use picosecond pulse laser with a center wavelength of 1064nm and a pulse width of 10 picoseconds. The laser beam is deflected by a galvanometer, and then focused on a rectangular block copper surface through a scene with a focal length of 100mm. The diameter of the focal spot is 30μm. The bulk copper has an area of 25mm×25mm and a thickness of 3mm.

[0066] The laser parameters are: the average power is 18W, the pulse frequency is 100kHz, the laser deflection...

Embodiment 2

[0070] Example 2. Picosecond pulsed laser preparation of micro-nano precursor structure on Cu surface to realize patterned growth of CuO nanowires

[0071] The controllable patterning preparation of CuO nanowires in this embodiment includes the following steps:

[0072] (1) Remove the oxide layer on the surface of the bulk Cu by mechanical grinding, and make the surface reach a certain degree of smoothness, then clean the Cu surface with alcohol, and blow or dry the surface of the Cu block after cleaning.

[0073] (2) Use picosecond pulse laser with a center wavelength of 1064nm and a pulse width of 10 picoseconds. The laser beam is deflected by a galvanometer, and then focused on a rectangular block copper surface through a scene with a focal length of 100mm. The diameter of the focal spot is 30μm. The bulk copper has an area of 25mm×25mm and a thickness of 3mm.

[0074] The laser parameters are: the average power is 18W, the pulse frequency is 100kHz, the laser deflection...

Embodiment 3

[0078] Example 3. Femtosecond pulsed laser preparation of micro-nano precursor structure on Cu surface to realize patterned growth of CuO nanowires

[0079] The controllable patterning preparation of CuO nanowires in this embodiment includes the following steps:

[0080] (1) Remove the oxide layer on the surface of bulk Cu by grinding, and make the surface reach a certain degree of smoothness, and then clean the Cu surface with alcohol.

[0081] (2) Femtosecond pulsed laser is selected, with a central wavelength of 1064nm and a pulse width of 800 femtoseconds. The laser beam is deflected by a galvanometer, and then focused on a rectangular block copper surface through a scene with a focal length of 100mm, and the focal spot diameter is 30μm. The bulk copper has an area of 30mm×30mm and a thickness of 1mm.

[0082] The laser parameters are: the average power is 15W, the pulse frequency is 200kHz, the laser deflection track is parallel lines, the line spacing is 50μm, the sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com