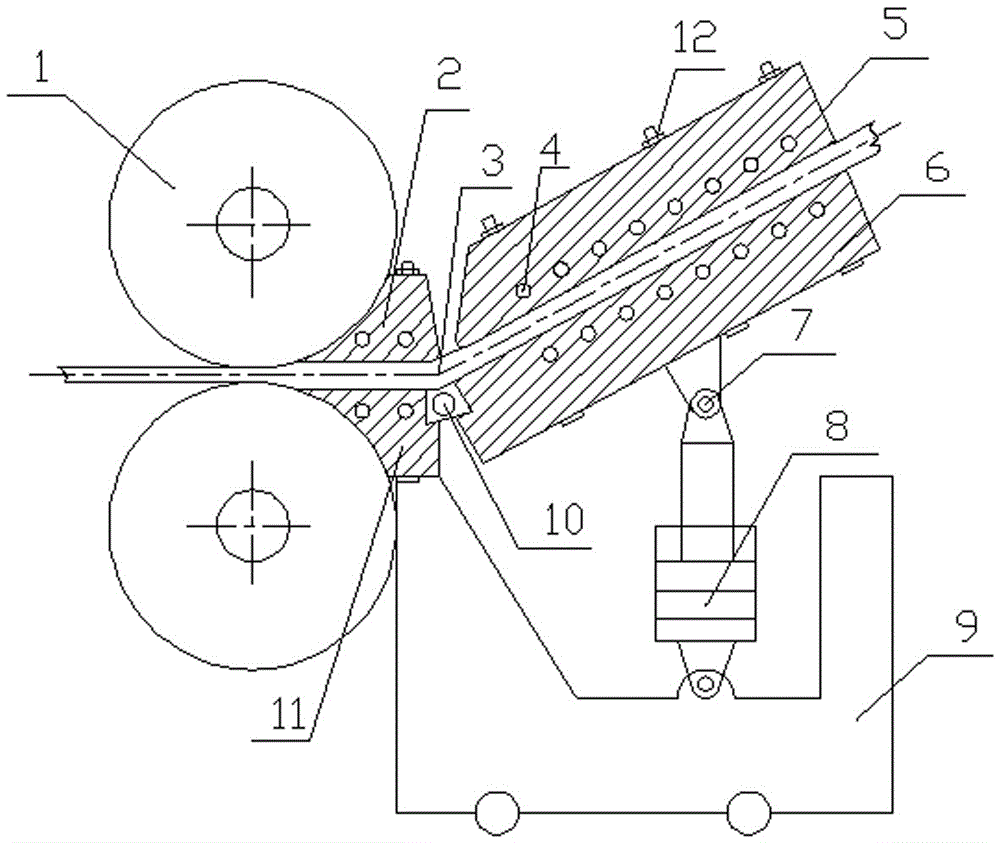

Method and device for strong shear rolling forming of metal sheet

A metal plate and strong shearing technology, which is applied in the direction of metal rolling, metal rolling, forging and pressing equipment, etc., can solve the problems of inconvenient angle of the equal diameter angle of the mold, inability to extrude the mold, high cost, etc., and achieve large-scale Effects of industrialized production, improvement of mechanical properties, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: AZ61 magnesium alloy plate rolling

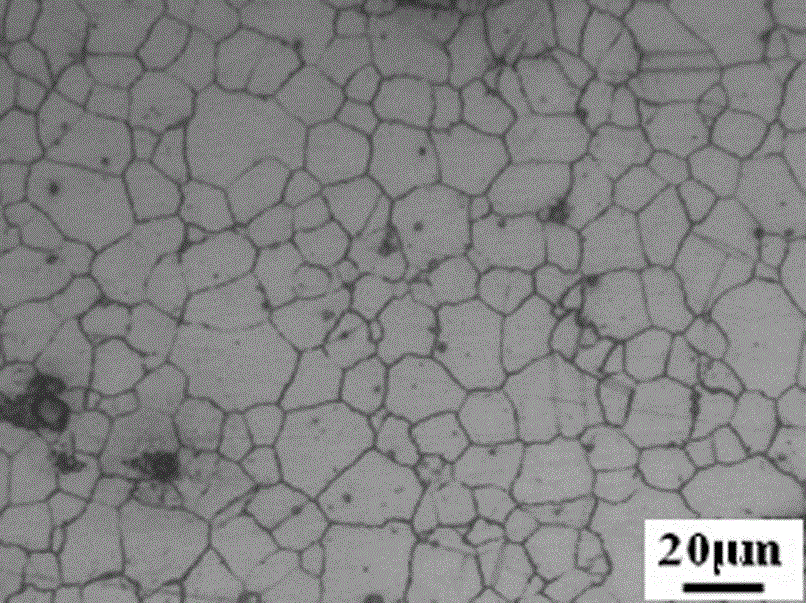

[0029] The blanks are two pieces of AZ61 magnesium alloy extruded plates (sample numbers are #1 and #2), the size before rolling is 500mm×100mm×5mm, the metallographic microstructure of the plate before rolling is as follows: figure 2 As shown, its average grain size is 21.5 μm. Adopt method and device designed by the present invention to carry out following experiment to sample 1:

[0030] (1) Unload the oil cylinder 8 so that the lower template 6 of the movable mold is placed flat on the machine base 9, and the AZ61 magnesium alloy plate 3 to be rolled is placed between the upper template 2 of the fixed mold and the lower template 11 of the fixed mold and the movable mold The metal plate passage between the upper formwork 5 and the lower formwork 6 of the movable mold, and the plate is stretched out from the outlet of the metal plate passage.

[0031] (2) Use a wrench to adjust the bolts between the upper template ...

Embodiment 2

[0041] Embodiment 2: 6016 aluminum alloy plate rolling

[0042] Two pieces of 26mm thick 6016 aluminum alloy ingots (sample numbers are respectively #3 and #4), adopt the method and device designed by the present invention to carry out following experiments: adopt the method similar to embodiment 1, put into billet #3 ( The mold is preheated to 450°C, and the billet is kept at 450°C for 2 hours), and the 6016 plate is rolled to a thickness of 2 mm through multiple passes, and then samples are taken for metallographic observation and mechanical property testing. As a comparison, the #4 sample was deformed by ordinary rolling, and the rolling temperature, pass deformation and total deformation were all consistent with #3.

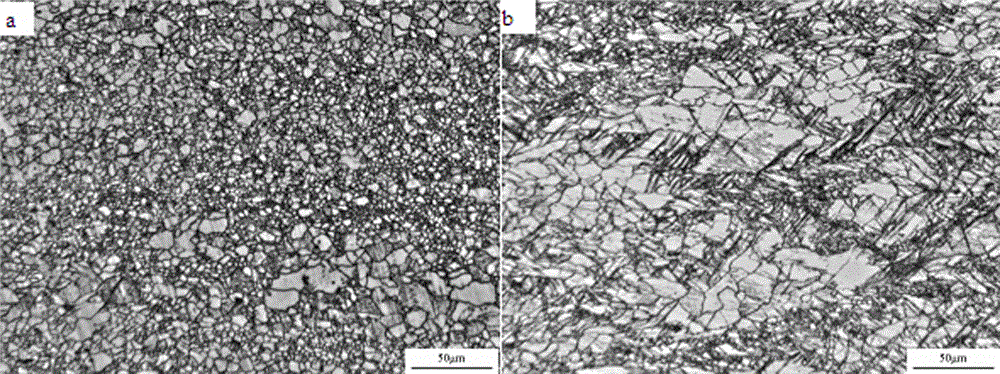

[0043] After rolling deformation, the pole figures of #3 and #4 plates are as follows Figure 4 (a) and (b) shown. It can be seen from the figure that after the strong shear deformation of the mold at an angle of 120 °C, the #3 plate formed an obvious shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com