Bola type polyether-modified organosilicon surfactant and preparation method thereof

A surfactant and polyether modification technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve problems such as expensive, unreported, cumbersome synthesis methods, etc., to ensure environmental safety, Excellent surface activity, rich variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Bisaminopropyl-terminated Polysiloxane

[0038] Add hexamethylcyclotrisiloxane 55.6Kg (250mol), 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane 12.4Kg ( 50mol), tetramethylammonium hydroxide 0.45Kg (5mol), heating and dissolving, the temperature is controlled at 20 ° C, after 50 hours of reaction, the temperature is raised to 140 ° C to deactivate the catalyst, and the excess raw materials are removed by vacuum distillation to obtain bisaminopropyl end-blocked polysiloxane.

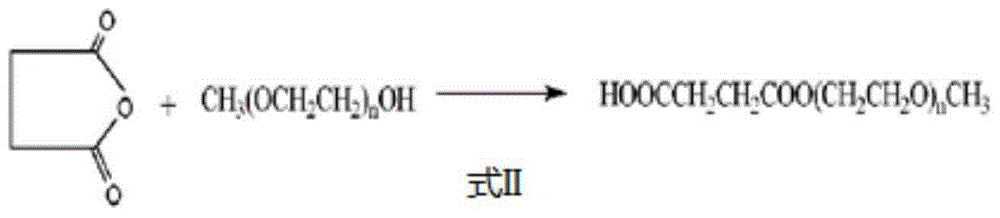

[0039] Preparation of Polyethylene Glycol Monomethyl Ether Succinate

[0040] Add polyethylene glycol monomethyl ether 1200 (MPEG-1200) 600.0Kg (500mol) into the reaction kettle, heat up to 60°C, after the MPEG is dissolved, add 50.0Kg (500mol) of succinic anhydride, and add p-toluenesulfonic acid The amount is 130Kg (accounting for 20% of the total mass of polyethylene glycol monomethyl ether and succinic anhydride). After the materials are fully dissolved, keep warm for 30 hou...

Embodiment 2

[0044] Preparation of Bisaminopropyl-terminated Polysiloxane

[0045] Add octamethylcyclotetrasiloxane 222.5Kg (750mol), 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane 12.4Kg ( 50mol), tetramethylsiliconol ammonium 0.18Kg (0.5mol), heating to dissolve, the temperature is controlled at 60 ° C, after 25 hours of reaction, the temperature is raised to 140 ° C to deactivate the catalyst, and the excess raw materials are removed by vacuum distillation to obtain diaminopropyl Group-terminated polysiloxane.

[0046] The preparation of monopolyethylene glycol monomethyl ether succinate is the same as in Example 1.

[0047] Preparation of Bola-type Polyether Modified Silicone Surfactant

[0048] In the reactor, add 469.7Kg (100mol) of bisaminopropyl-terminated polysiloxane, 1560Kg (1200mol) of monopolyethylene glycol monomethyl ether succinate, and use ethanol as a solvent, and react at reflux temperature for 20h, Cool, filter to remove unreacted raw materials, evaporate the s...

Embodiment 3

[0050] Preparation of Bisaminopropyl-terminated Polysiloxane

[0051] Add decamethylcyclopentasiloxane 556.2Kg (1500mol), 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane 12.4Kg ( 50mol), sodium hydroxide 0.1Kg (2.5mol), heat to dissolve, the temperature is controlled at 120 ° C, after 5 hours of reaction, add acid to neutralize, deactivate the catalyst, and rectify under reduced pressure to remove excess raw materials to obtain diaminopropyl capping polysiloxane.

[0052] The preparation of monopolyethylene glycol monomethyl ether succinate is the same as in Example 1.

[0053] Preparation of Bola-type Polyether Modified Silicone Surfactant

[0054] Add 1137Kg (100mol) of bisaminopropyl-terminated polysiloxane, 2600Kg (2000mol) of monopolyethylene glycol monomethyl ether succinate in the reaction kettle, use propanol as solvent, and react at reflux temperature for 30 hours , cooled, filtered to remove unreacted raw materials, evaporated to remove the solvent, and vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com