Manufacturing method of tunable quantum well laser epitaxial chips of large lattice mismatch

A technology of lattice mismatch and fabrication method, applied in lasers, phonon exciters, laser parts and other directions, can solve the problems of low height, carriers are easy to escape from potential wells, lasers cannot work stably, etc. Tuning to achieve a wide range of wavelengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

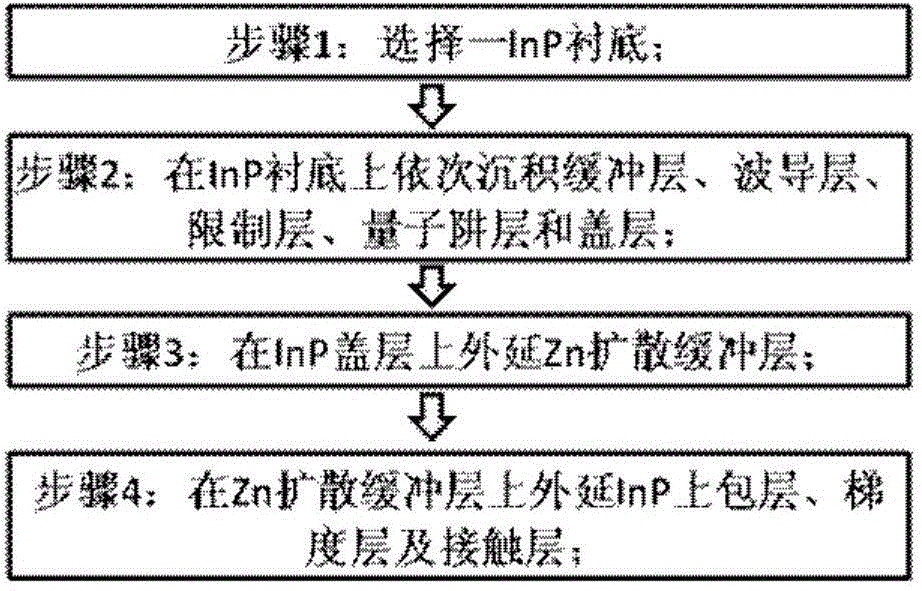

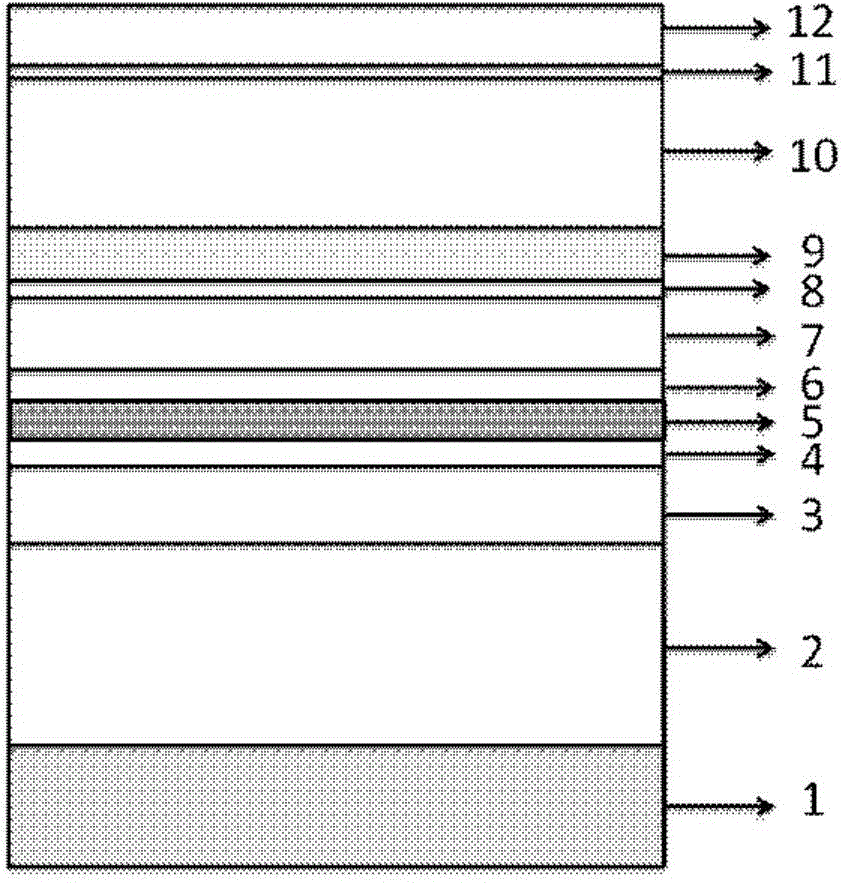

[0015] see figure 1 , figure 2 As shown, a method for manufacturing a large lattice mismatch tunable quantum well laser epitaxial chip of the present invention comprises the following steps:

[0016] Step 1: Select an InP substrate 1, wherein the InP substrate 1 is an InP single wafer, the crystal orientation is (001), the off angle is within ±0.5°, the thickness is 325-375 μm, and the doping concentration is (2-6) ×10 18 cm -3 ;

[0017] Step 2: On the substrate 1, deposit an InP buffer layer 2, a lower waveguide layer 3, a lower confinement layer 4, a quantum well layer 5, an upper confinement layer 6, an upper waveguide layer 7, and an InP capping layer 8; the InP buffer layer 2 The thickness is 500nm, the growth temperature is between 600 and 660°C, and the doping concentration is between 1×10 17 to 2×10 18 cm -3 Between, the growth rate is about 0.4-0.6nm / s, too fast growth rate is not conducive to the formation of high-quality buffer layer; wherein the material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com