Method for preparing flax fiber by combined process of mucor circinelloides DK1 strain and hydrogen peroxide

A technology of Mucor circinifolia and hydrogen peroxide, applied in the direction of producing bast fibers based on microorganisms, chemical methods, biochemical equipment and methods, etc., can solve the problem of not being able to meet the needs of high-grade and high-count fabrics, and the quality of degumming affects the appearance of fabrics. Long time degumming process and other problems, to achieve the effect of favorable environmental protection, strong anti-pollution ability, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

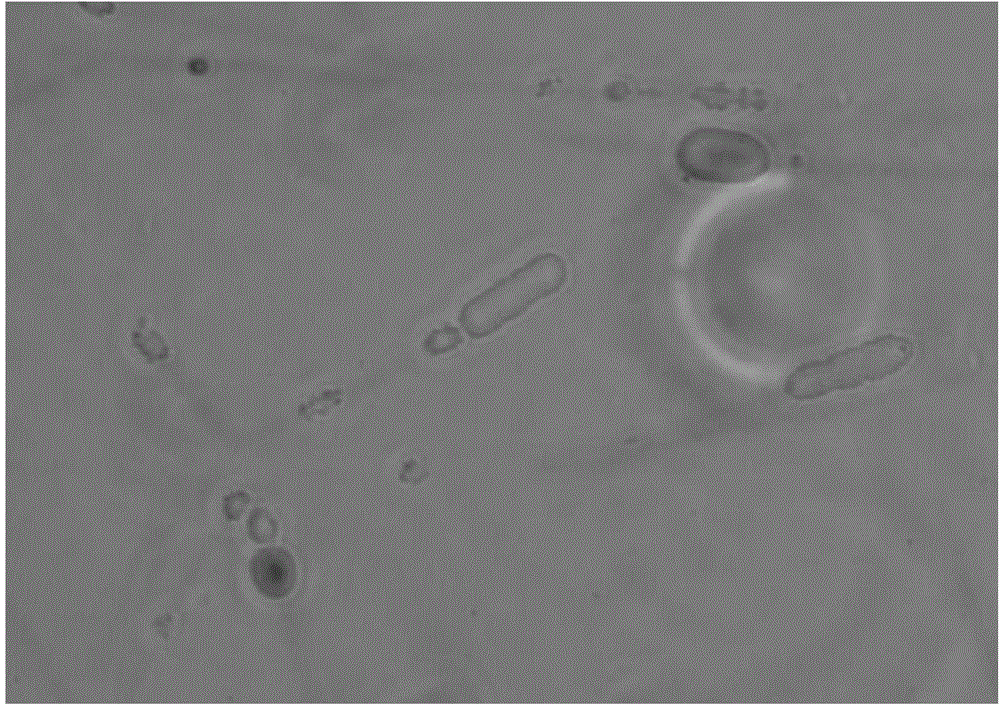

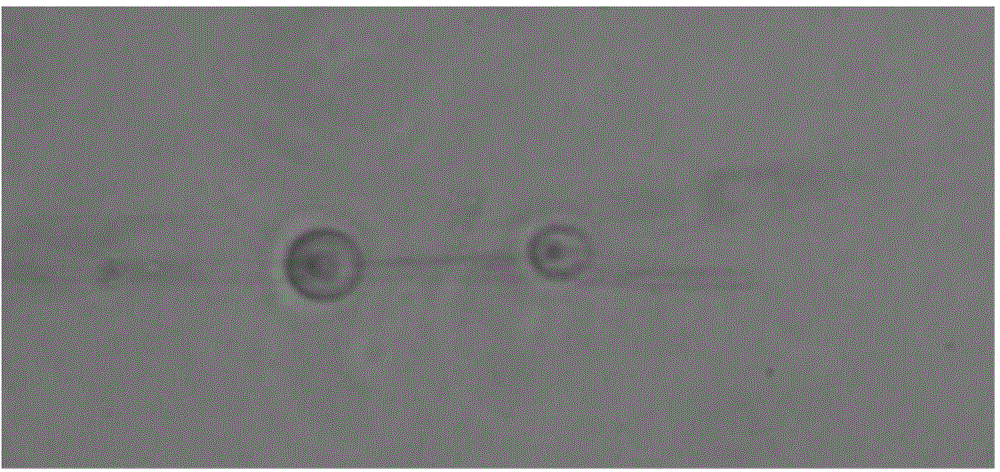

Image

Examples

Embodiment 1

[0027] This embodiment records the method for preparing the degumming enzyme liquid by Mucor circiniferatum DK1:

[0028] (1) Preserve Mucor circinatus DK1 strain in PDA medium, culture at 200 rpm at 30°C for 24 hours, add freezing buffer; Into a 300mL Erlenmeyer flask, insert the obtained bacteria loop, and culture in a shaker at 150rpm at 28°C for 3 days, then culture the 50ml shaker flask, inoculate the culture medium into 5L of flax fermentation medium, and inoculate at a speed of 200r / min , Shake flask culture at a temperature of 30°C for 24 hours to obtain a fermentation broth. The fermentation broth was filtered through sterile gauze, the mycelium was washed with sterile water and dispersed in a Waring high-speed crushing cup for 10 seconds, and collected in sterile water. (with the same volume as the fermentation broth) to make a suspension of mycelium, and store it at 40°C for future use.

[0029] The formula of freezing buffer per 100ml is: potassium dihydrogen phos...

Embodiment 2

[0035] The process of preparing laccase and hydrogen peroxide from the strain Mucor crimperida DK1 for the degumming of flax raw stems is as follows:

[0036] Put 5g of flax raw stems in a 250ml Erlenmeyer flask, and divide the mixture of flax stems, crude enzyme solution and hydrogen peroxide into the conical flask at a ratio of 1:20 (w / v), the liquid volume is 100ml, and the pH of the mixture is The value is 6.0, the mass ratio of the original flax stem to the hydrogen peroxide is 1:5, and the mass ratio to the crude enzyme solution is 1:15. Degumming at 40°C and 200rpm shaker for 1 day, 2 days and 4 days respectively, after the time reaches the set time, add 10% sodium hydroxide, set the temperature at 75°C, the heating rate is 1°C / min, and the time is 5 hours. When the degumming time is over, remove the degumming liquid, rinse several times with tap water, to remove bacteria and non-cellulose substances on the original flax stem, and complete degumming.

[0037] Through t...

Embodiment 3

[0039] The process of combining Mucor circinari DK1 and hydrogen peroxide for ramie yarn is as follows:

[0040] Put 5g of ramie sterilized yarn (ramie roving or ramie spun yarn) into a 250ml Erlenmeyer flask, and distribute the mixture of ramie yarn, crude enzyme solution and hydrogen peroxide at 1:20 (w / v) in the Erlenmeyer flask, The liquid volume is 100ml, the pH value of the mixed liquid is 7.0, the mass ratio of ramie yarn to hydrogen peroxide is 1:1, and the mass ratio to crude enzyme solution is 1:19. Degumming in 10°C, 10rpm shaker for 10min, add 0.5% sodium hydroxide after the set time, set temperature at 50°C, heating rate 10°C / min, time 10min, when the degumming time is up, remove the degumming solution , Rinse several times with tap water to remove bacteria and non-cellulose substances on the ramie yarn and complete degumming.

[0041] The observation of ramie yarn degumming found that after degumming, the softness and whiteness of ramie yarn increased, and the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com