Camellia saponin natural dishwashing liquid

A technology of camellia saponin and detergent, which is applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., to achieve the effects of excellent emulsification, good ability to complex metal ions, and good thickening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

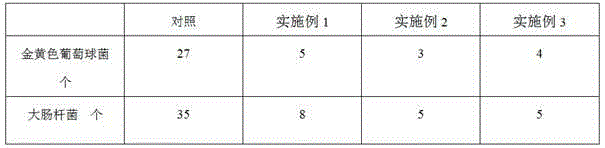

Examples

Embodiment 1

[0013] 1. Take 6 parts of Camellia oleifera saponins, 2 parts of Platycodon grandiflora total saponins, 2 parts of adzuki bean saponins, 2 parts of saponins, 10 parts of ethanol, 0.3 parts of citric acid, 0.5 parts of sodium citrate, 0.5 parts of sodium chloride, 45 parts of deionized water share.

[0014] Heat deionized water to 60°C and add different saponins. During the process, control the temperature at 60°C, stir for 30 minutes, then drop the temperature to 40°C, add ethanol and sodium citrate, adjust the pH to 7.5 with citric acid, and finally add sodium chloride Then adjust the viscosity.

Embodiment 2

[0016] 2. According to the following weight fraction ratio, 10 parts of camellia oleifera saponins, 1 part of platycodon grandiflora total saponins, 1 part of adzuki bean saponins, 1 part of saponins, 5 parts of ethanol, 0.1 parts of citric acid, 0.1 parts of sodium citrate, and 0.1 parts of sodium chloride parts, 40 parts of deionized water.

[0017] Heat deionized water to 60°C and add different saponins. During the process, the temperature is controlled at 65°C. Stir for 30 minutes until the temperature drops to 40°C. Add ethanol and sodium citrate, adjust the pH with citric acid, and finally add sodium chloride to adjust viscosity.

Embodiment 3

[0019] 3. Prepare according to the following weight fractions, 8 parts of camellia saponins, 2 parts of platycodon total saponins, 1 part of adzuki bean saponins, 1 part of saponins, 7 parts of ethanol, 0.3 parts of citric acid, 0.3 parts of sodium citrate, sodium chloride 0.3 parts, 45 parts of deionized water. Heat deionized water to 60°C and add different saponins. During the process, the temperature is controlled at 63°C. Stir for 30 minutes until the temperature drops to 40°C. Add ethanol and sodium citrate, adjust the pH with citric acid, and finally add sodium chloride to adjust viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com