Epoxy resin compound for sealing semiconductor and semiconductor device

A technology of epoxy resin and composition, applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as doubts about reliability characteristics, and achieve excellent hot water extraction characteristics and high-temperature storage reliability. Excellent effect with excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] Examples and comparative examples of epoxy resin compositions are shown below to specifically illustrate the present invention, but the present invention is not limited by the following examples.

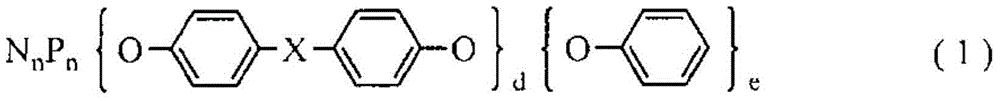

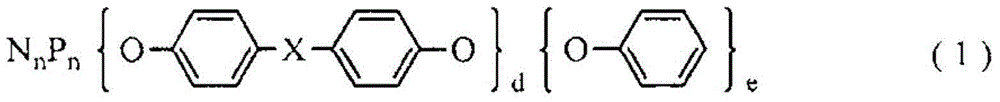

Synthetic example A

[0082] Under a nitrogen atmosphere, 4.8 g (119 mmol) of sodium hydroxide (NaOH) was suspended in 50 ml of tetrahydrofuran (THF) at 0°C, and 10.2 g (108 mmol) of phenol, 4,4'-sulfonyldiphenol 0.45g (1.8mmol) of THF50ml solution. After stirring for 30 minutes, a THF50 ml solution of 12.5 g (36.0 mmol) of hexachlorotriphosphazene was added dropwise, and the mixture was heated to reflux for 5 hours. Into this, 5.2 g (130 mmol) of sodium hydroxide (NaOH) was suspended in 50 ml of THF at 0°C, and a solution of 11.2 g (119 mmol) of phenol in 50 ml of THF was added dropwise thereto, followed by further heating and reflux for 19 hours. After the solvent was distilled off under reduced pressure, chlorobenzene was added, dissolved, and extracted with 200 ml x 2 of 5 mass % NaOH aqueous solution, 200 ml x 2 of 5 mass % sulfuric acid aqueous solution, 200 ml x 2 of 5 mass % sodium bicarbonate aqueous solution, and 200 ml x 2 of water . The solvent was distilled off under reduced pressure...

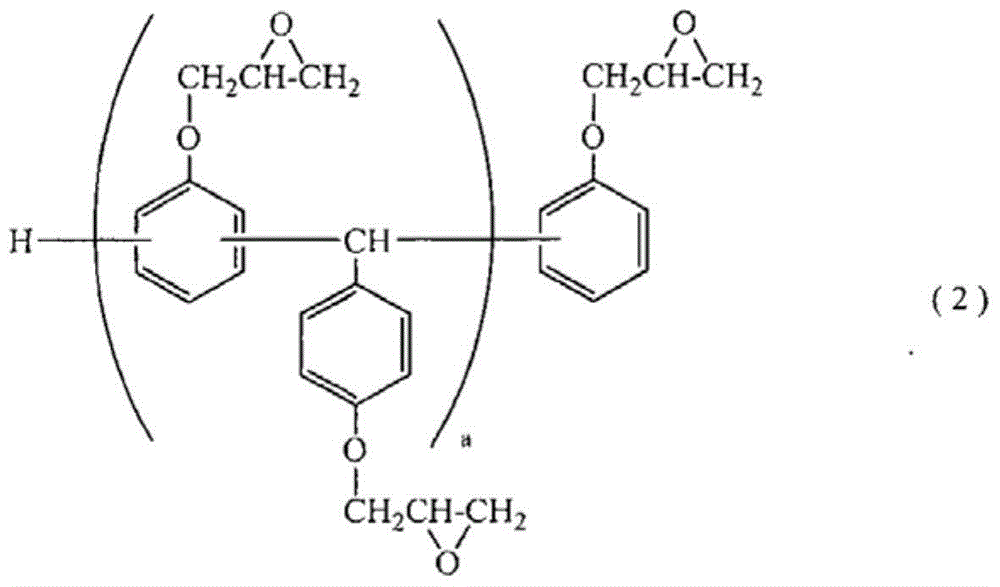

Embodiment 1~5、 comparative example 1~7

[0086] The components shown in Tables 1 and 2 were uniformly melt-mixed with hot twin rolls, cooled, and pulverized to obtain an epoxy resin composition for semiconductor sealing. Using these compositions, each characteristic of the following (i)-(iv) was measured, and the results are shown in Tables 1 and 2 together.

[0087] (i) Flame retardancy

[0088] Based on the UL-94 standard, the flame retardancy of a 1 / 16 inch thick board was examined. Furthermore, a 1 / 16-inch thick plate is passed at a temperature of 175°C and a forming pressure of 6.9N / mm 2 1. Molded under the condition of molding time of 120 seconds, and post-cured at 180°C for 4 hours.

[0089] (ii) Adhesion to Cu / Ag plated lead frame stored at high temperature

[0090] At a temperature of 175°C and a molding pressure of 6.9N / mm 21. Mold the epoxy resin composition on a 100pin-QFP frame (Cu alloy C7025, Ag plating on the die pad) under the condition of molding time of 120 seconds, and post-cure at 180° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com