Preparation method of silicon dioxide aerogel composite material for low-temperature cold insulation

A technology of composite materials and silica, which is applied in the field of preparation of silica airgel composite materials for low-temperature insulation, can solve the problems of loss of cold insulation effect, inconvenient pipeline arrangement, poor cold insulation effect, etc., and achieve low water absorption, The effect of low maintenance cost and simple cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

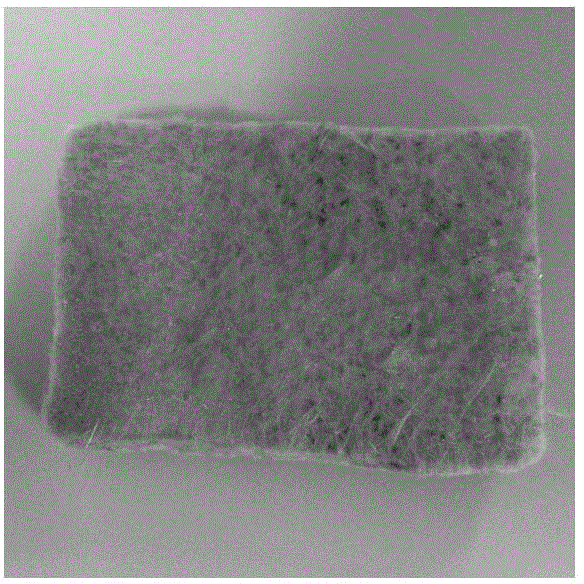

example 1

[0027] Example 1 Add tetraethyl orthosilicate and ethanol solution in a beaker, stir magnetically, heat to 50°C, keep the temperature constant, add water, and add a small amount of hydrochloric acid to adjust the pH to 4.5, continue stirring for 30 minutes, add MTES (methyl triethyl Oxysilane), continue to stir for 60min. A small amount of ammonia water was added to adjust the pH of the solution to 6.5, and the stirring was continued for 15 min. Wherein, the molar ratio of tetraethyl orthosilicate, ethanol, water, and modifier is 1:0.5:18:4. Slowly pour the sol into the mold with the basalt fiber felt. After the gel is complete, add ethanol solution into the stainless steel mold with wet gel, subject to the fact that the gel is not covered, cover the surface with a film and put it in an oven at 50°C for aging for 2 days; pour out the ethanol aging solution after 2 days, replace Fresh pure ethanol solution was aged again for 2 days. The obtained gel composite material was su...

example 2

[0029] Example 2 Add tetraethyl orthosilicate and ethanol solution in a beaker, stir magnetically, heat to 40°C, keep the temperature constant, add water, and add a small amount of sulfuric acid to adjust the pH to 5, continue stirring for 60min, add MTES (methyl triethyl Oxysilane), continue to stir for 75min. A small amount of ammonia water was added to adjust the pH of the solution to 7, and stirring was continued for 5 min. Wherein, the molar ratio of tetraethyl orthosilicate, ethanol, water, and modifier is 1:0.5:8:4. Slowly pour the sol into the mold with the basalt fiber felt. After the gel is complete, add ethanol solution into the stainless steel mold with wet gel, subject to the fact that the gel is not covered, cover the surface with a film and put it in an oven at 50°C for aging for 1 day; pour out the ethanol aging solution after 1 day, replace Fresh pure ethanol solution was aged again for 1 day. The obtained gel composite material was supercritically dried wi...

example 3

[0031] Example 3 Add tetraethyl orthosilicate and ethanol solution in a beaker, stir magnetically, heat to 60°C, keep the temperature constant, add water, and add a small amount of nitric acid to adjust the pH to 5, continue stirring for 45min, add PTES (phenyl triethyl Oxysilane), continue to stir for 90min. A small amount of ammonia water was added to adjust the pH of the solution to 7, and stirring was continued for 15 min. Among them, the molar ratio of tetraethyl orthosilicate, ethanol, water, and modifier is 1:0.1:12:2, and the sol is slowly poured into a mold with basalt fiber felt. After the gel is complete, add ethanol solution into the stainless steel mold with wet gel, as long as the gel is not covered, cover the surface with a film and put it in an oven at 70°C for aging for 2 days; pour out the ethanol aging solution after 2 days, replace Fresh pure ethanol solution was aged again for 2 days. Altogether, the ethanol aging solution was replaced 3 times, each agin...

PUM

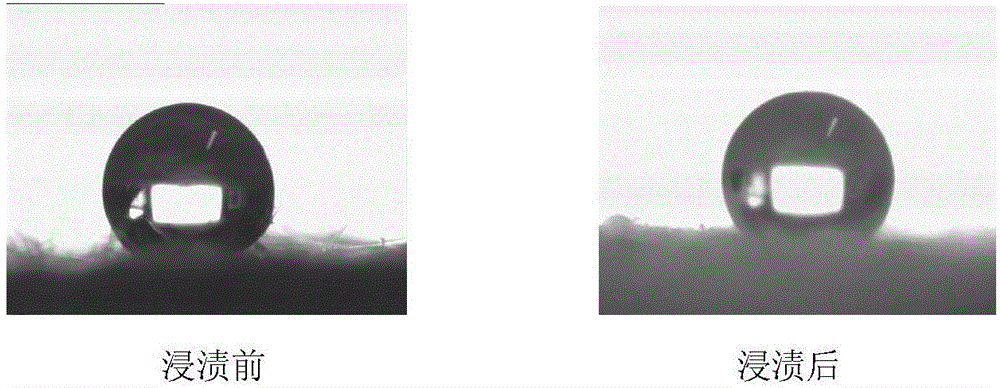

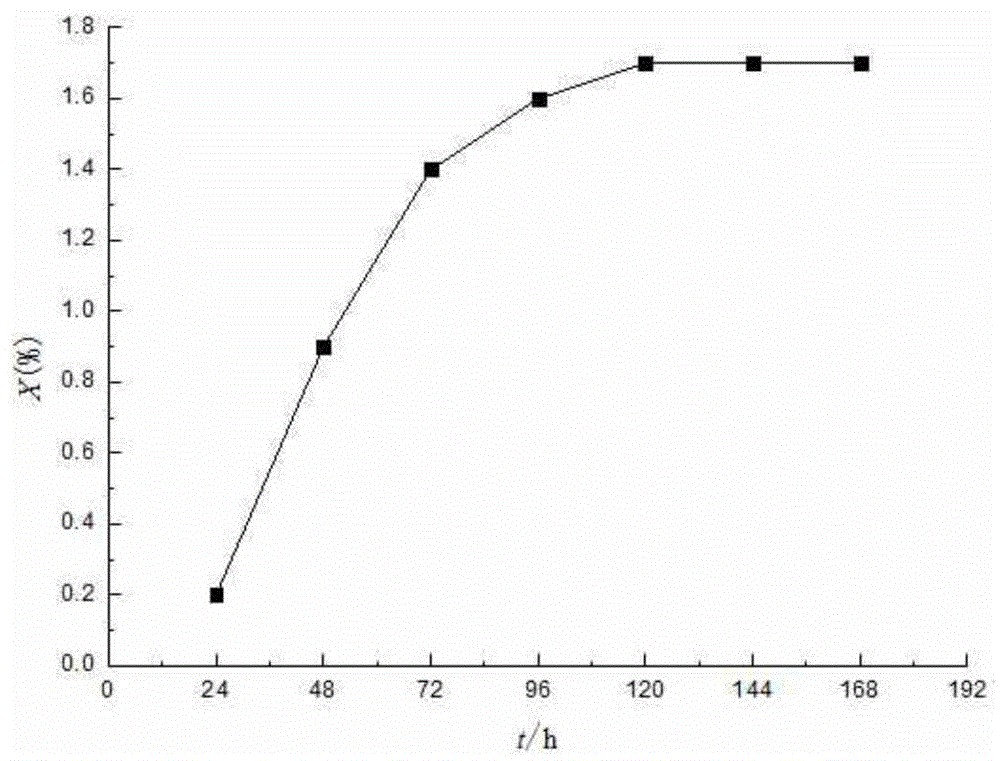

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com