Solvothermal preparation method of silicon-surface vertically-assembled CeO2 nanorod film

A technology of vertical assembly and nanorods, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of silicon wafer erosion, preparation of nano-CeO thin films, etc., and achieve simple equipment, high transparency of visible light, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

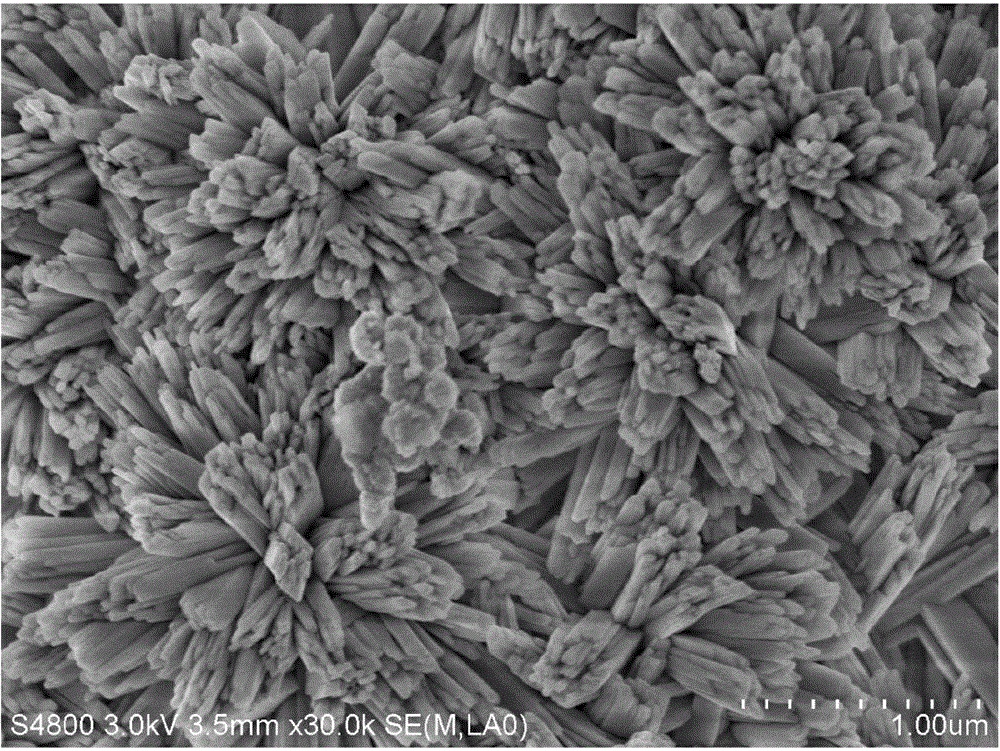

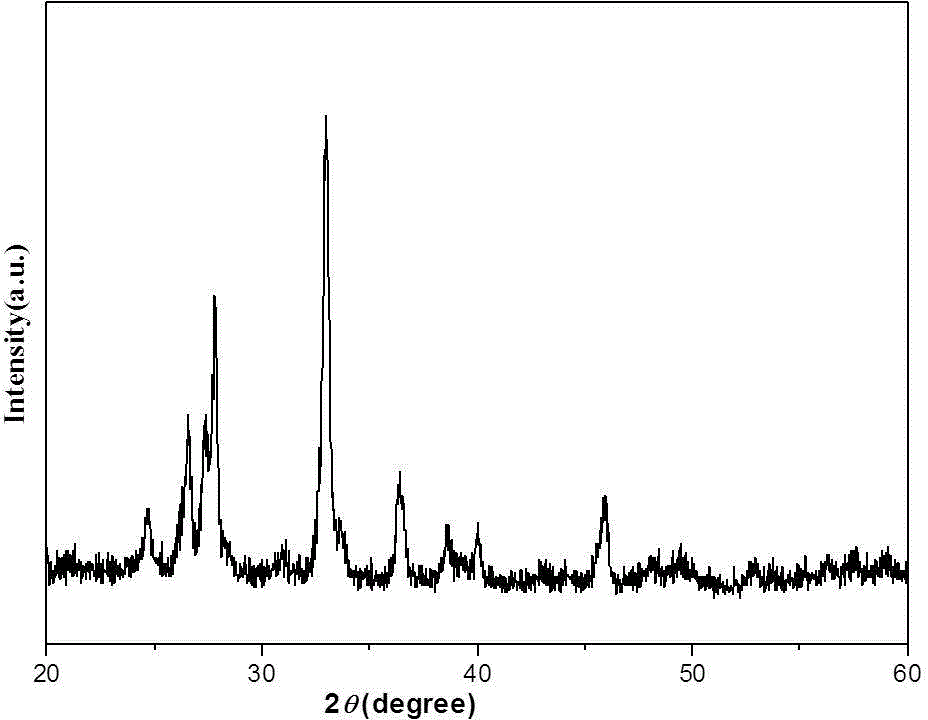

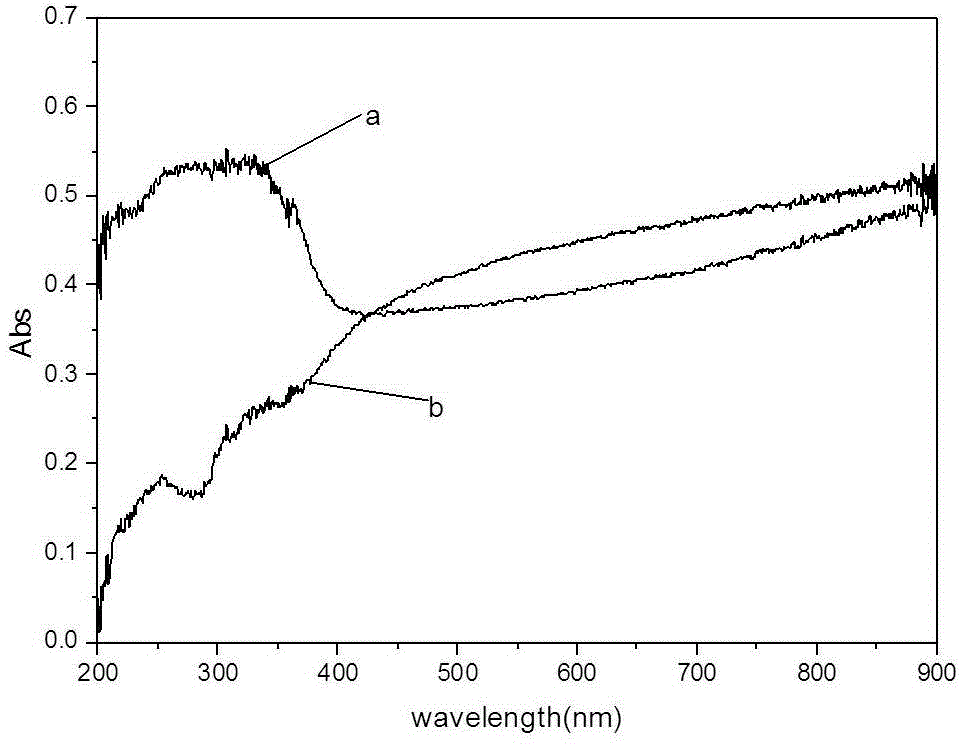

[0022] The invention provides a kind of silicon surface vertical assembly CeO 2 The solvothermal preparation method of nanorod film has simple equipment, low film production cost, no need for high temperature treatment of silicon substrate and film, and CeO with strong ultraviolet absorption ability and strong luminescence 2 Nanorods are assembled on a silicon wafer, and the resulting film is made of CeO 2 (The XRD spectrum of the film is as figure 2 shown) nanorods assembled vertically (SEM photo of the film is shown in figure 1 shown), uniform, high transparency of visible light, good adhesion, strong UV resistance (UV spectrum as shown image 3 shown), and has a strong emission peak at 380-390nm (the emission spectrum is shown in Figure 4 Shown), it is widely used in the anti-ultraviolet performance of crystalline silicon solar cells. CeO assembled vertically on silicon wafer surface 2 The nanorod film has a diameter of 30-50nm, a film thickness of about 170 nm, a go...

Embodiment 1

[0030] Feed CeCl 3 ·7H 2 O is dissolved in absolute ethanol to obtain 0.01mol / L CeCl 3 solution in absolute ethanol, add 0.02mol / L CO(NH 2 ) 2 , urea and CeCl 3 The molar ratio of the mixture is 2:1, and the mixture is evenly stirred to obtain a precursor solution. Put the clean silicon wafer into a polytetrafluoroethylene-lined reactor, add the precursor solution (filling degree is 70%), seal it, place it in an oven, and react at 200°C for 3 hours. After the reaction is finished, the silicon chip is taken out after naturally cooling down to room temperature, washed with ethanol and water respectively, and dried to obtain the product.

Embodiment 2

[0032] Feed CeCl 3 ·7H 2 O is dissolved in absolute ethanol to obtain 0.015mol / LCeCl 3 solution in absolute ethanol, add 0.03mol / L CO(NH 2 ) 2 , urea and CeCl 3 The molar ratio of the mixture is 2:1, and the mixture is evenly stirred to obtain a precursor solution. Put the clean silicon wafer into a polytetrafluoroethylene-lined reactor, add the precursor solution (filling degree is 70%), seal it, place it in an oven, and react at 180°C for 4 hours. After the reaction is finished, the silicon chip is taken out after naturally cooling down to room temperature, washed with ethanol and water respectively, and dried to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com