Gear hobbing tool as well as an insert holder, a chip removal unit, and an insert kit therefor

A technology of inserts and tools, applied to components with teeth, gear cutting tools, gear teeth manufacturing tools, etc., can solve the problems of time-consuming measurement and adjustment, loss of tolerance chain, etc., and achieve the effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

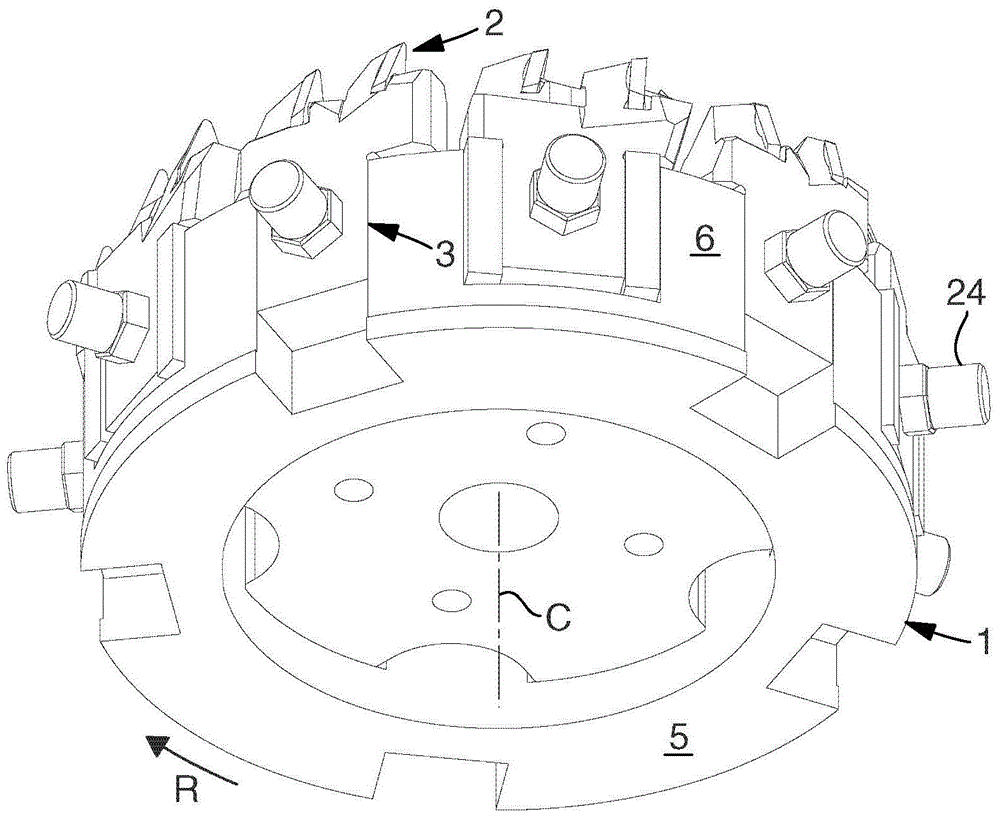

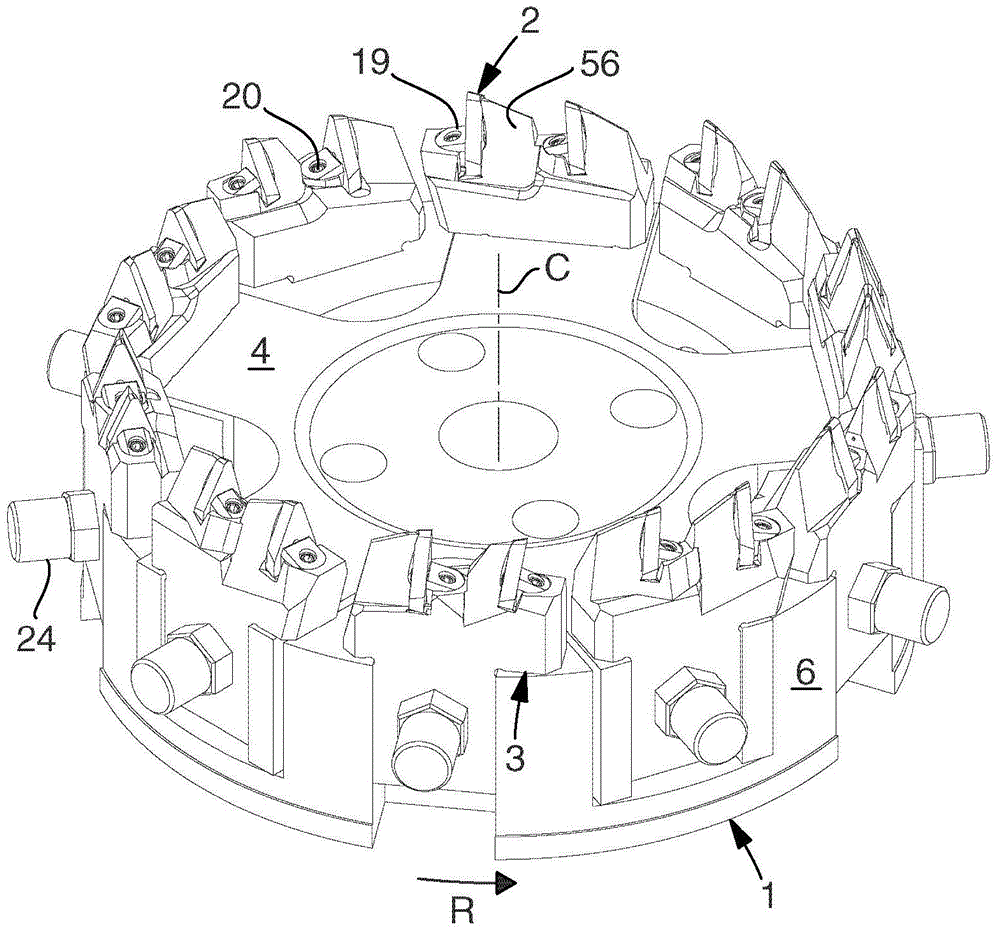

[0043] exist Figure 1-5 In , the construction of a tool according to the invention is shown, the basic parts of which are a milling cutter head (also referred to as “base body”) generally designated 1 and a plurality of replaceable milling inserts generally designated 2 . Each such milling insert is removably mounted in a chip removal unit, generally designated 3 , which in turn is removably mounted in the head 1 . The head 1 is rotatable in the direction R about a central axis denoted C, and the head 1 is obtained by, on the one hand, comprising a pair of generally flat front sides 4 and rear sides 5 parallel to each other and, on the other hand, having a cylindrical Or the outer peripheral surface 6 of a rotationally symmetrical shape, but has a basic shape of a disc or a pulley. In practice, the peripheral surface 6 takes the form of a plurality of partial surfaces which are collectively tangent to an imaginary circle. exist Figure 5 In , RP designates a reference plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com