Function protective material of extra-large round billet peritectic steel continuous casting crystallizer

A technology for continuous casting mold and protective material, applied in the field of metallurgical auxiliary materials, can solve the problems of reducing the heat transfer rate of the solidified shell to the mold, uneven temperature gradient distribution, uneven thermal stress distribution, etc., to promote the technical progress of the industry , Solve surface defects, improve the effect of product lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

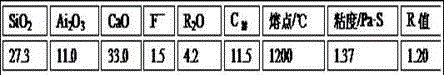

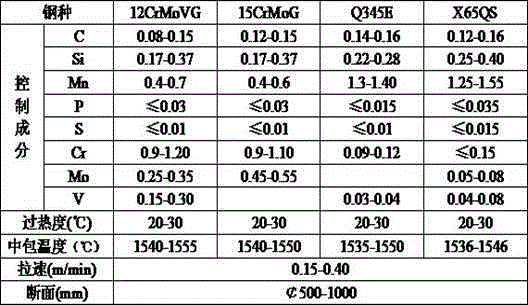

[0012] Example 1: A functional protection material for a peritectic steel continuous casting crystallizer of an extra large round billet, which is composed of the following components, each component and its component content are calculated by mass percentage: premelt: 55 parts, calcite: 3 parts, sodium carbonate: 2 parts, fluorite: 12 parts, high alumina: 2 parts, cryolite: 3 parts, lithium carbonate: 2 parts, carbon black: 1.8 parts, graphite carbon: 6 parts.

[0013] Further, the active ingredient percentage of the protective material is SiO 2 : 23.3%, CaO: 28.3%, Li 2 O: 1.0%, Al 2 o 3 : 10.5%, K 2 O+Na 2 O: 2.5%, F - : 0.93%, MgO: 0.65%, Fe 2 o 3 : 1.8%.

[0014] The premelt composition includes: SiO 2 : 34.0%, CaO: 34.0%, Al 2 o 3 : 2.0%, R 2 O: 10.0%, F - : 7.0% and other trace elements.

Embodiment 2

[0015] Example 2: A functional protection material for a peritectic steel continuous casting crystallizer of an extra large round billet, which is composed of the following components, each component and its component content are calculated by mass percentage: premelt: 60 parts, calcite: 7 parts, sodium carbonate: 4 parts, fluorite: 18 parts, high alumina: 4 parts, cryolite: 5 parts, lithium carbonate: 3 parts, carbon black: 2.5 parts, graphite carbon: 10 parts.

[0016] Further, the active ingredient percentage of the protective material is SiO 2 : 28.9%, CaO: 34.2%, Li 2 O: 1.9%, Al 2 o 3 : 13.0%, K 2 O+Na 2 O: 6.2%, F - : 3.4%, MgO: 1.23%, Fe 2 o 3 : 2.6%.

[0017] The premelt composition includes: SiO 2 : 38.0%, CaO: 44.0%, Al 2 o 3 : 4.0%, R 2 O: 13.0%, F - : 8.5% and other trace elements.

Embodiment 3

[0018] Example 3: A functional protection material for a peritectic steel continuous casting crystallizer of an extra large round billet, which is composed of the following components, each component and its component content are calculated by mass percentage: premelt: 56 parts, calcite: 3.5 parts, sodium carbonate: 2.5 parts, fluorite: 13 parts, high alumina: 2.8 parts, cryolite: 3.4 parts, lithium carbonate: 2.2 parts, carbon black: 2.0 parts, graphite carbon: 7 parts.

[0019] Further, the active ingredient percentage of the protective material is SiO 2 : 25.2%, CaO: 30.2%, Li 2 O: 1.2%, Al 2 o 3 : 11.5%, K 2 O+Na 2 O: 3.5%, F - : 1.2%, MgO: 0.95%, Fe 2 o 3 : 2.3%.

[0020] The premelt composition includes: SiO 2 : 36.0%, CaO: 38.0%, Al 2 o 3 : 3.0%, R 2 O: 11.0%, F - : 7.5% and other trace elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com