Butyronitrile glove preventing static and production method thereof

A technology of nitrile gloves and a production method, applied in protective clothing, coatings and other directions, can solve problems such as anti-static problems of nitrile gloves, and achieve the effects of improving production efficiency and quality, protecting skin and enhancing anti-static performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

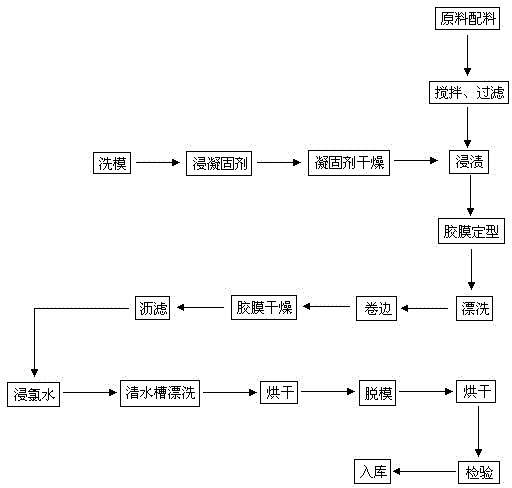

Image

Examples

Embodiment 1

[0021] An antistatic nitrile glove, comprising: 100 parts of nitrile rubber, 1.0 part of potassium hydroxide, 0.2 part of zinc di-n-butyldithiocarbamate, 0.15 part of defoamer, 0.3 part of antistatic liquid and 2.75 parts Auxiliary materials; wherein, the auxiliary materials include 0.5 parts of vulcanization accelerator, 1.25 parts of zinc oxide and 1.0 part of sulfur.

Embodiment 2

[0023] A kind of production method of antistatic nitrile gloves, comprises the steps:

[0024] a. Mix 100 parts of nitrile rubber, 1.0 part of potassium hydroxide, 0.2 part of zinc di-n-butyl dithiocarbamate, 0.15 part of defoamer and 2.75 parts of auxiliary materials, stir and filter dust impurities;

[0025] b. Dissolve 0.3 parts of antistatic liquid, add ammonia water and adjust the pH value to above 9.0, pass the pH meter test, put it into the nitrile mixture a, and mix to form an antistatic nitrile emulsion;

[0026] c. Carry out pickling of the hand model in turn: pH value 2, water washing, alkali washing: pH value 11 and drying operation;

[0027] d. Immerse the hand mold in the coagulant and dry it through the coagulant. The treatment temperature is controlled at 120°C;

[0028] e. Immerse the hand model in the rubber compound prepared in step b, and carry out the shaping, rinsing and curling process of the film;

[0029] f. Control the temperature at 120°C and dry t...

Embodiment 3

[0033] A kind of production method of antistatic nitrile gloves, comprises the steps:

[0034] a. Mix 100 parts of nitrile rubber, 1.0 part of potassium hydroxide, 0.2 part of zinc di-n-butyl dithiocarbamate, 0.15 part of defoamer and 2.75 parts of auxiliary materials, stir and filter dust impurities;

[0035] b. Dissolve 0.3 parts of antistatic liquid, add ammonia water and adjust the pH value to above 9.0, pass the pH meter test, put it into the nitrile mixture a, and mix to form an antistatic nitrile emulsion;

[0036] c. Carry out pickling of the hand model in turn: pH value 3, water washing, alkali washing: pH value 14 and drying operation;

[0037] d. Immerse the hand mold in the coagulant and dry it through the coagulant. The treatment temperature is controlled at 150°C;

[0038] e. Immerse the hand model in the rubber compound prepared in step b, and carry out the shaping, rinsing and curling process of the film;

[0039] f. Control the temperature at 150°C and dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com