Fresh frozen shrimp antifreeze agent

An antifreeze, shrimp technology, applied in the field of aquatic product quality safety and control, can solve the problems of high sweetness and calorie, non-conformity, low calorie, etc., achieve low sweetness and calorie, safe and efficient use, and reduce color change. dark effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

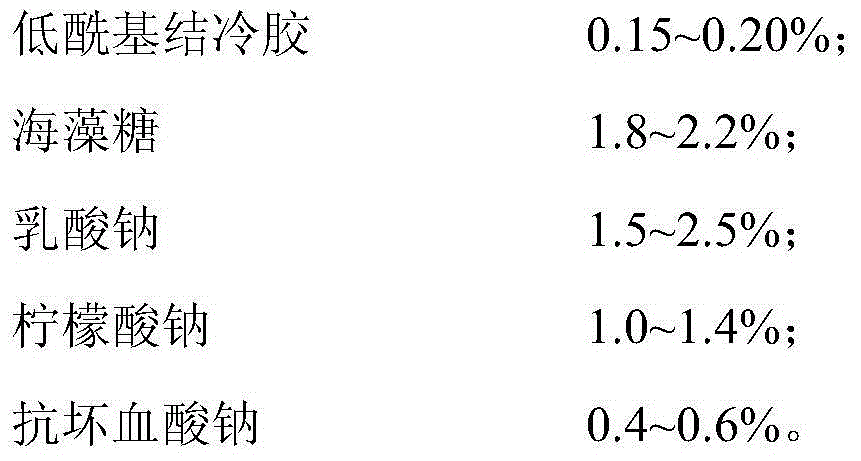

[0014] The aqueous solution system of the frozen shrimp antifreeze of the present embodiment includes the following mass concentration components: low acyl gellan gum 0.18%; trehalose 2.0%; sodium lactate 2.0%; sodium citrate 1.2%; sodium ascorbate 0.5%, wherein The molecular weight of low acyl gellan gum is 0.8×10 5 Da.

[0015] When preparing, just weigh the above components and dissolve them in deionized water. Use the configuration solution to soak the shrimps for 8-12 hours, then perform quick-freezing to prepare frozen shrimps, and observe the color of the shrimps after deep-frozen storage at -23~-12°C for 6 months No change, the loss of shrimp juice does not increase when thawing and heating, and maintains the original flavor and taste.

[0016] Table 1 Effect of adding antifreeze agent on thawing loss rate of frozen shrimp

[0017]

Embodiment 2

[0019] The aqueous solution system of the frozen shrimp antifreeze agent of the present embodiment includes the components of the following mass concentrations: 0.15% low acyl gellan gum; 2.2% trehalose; 1.5% sodium lactate; 1.4% sodium citrate; 0.4% sodium ascorbate, wherein The molecular weight of low acyl gellan gum is 1.0×10 5 Da.

[0020] When preparing, weigh the above components and dissolve them in deionized water. Use the configuration solution to soak the shrimps for 8-12 hours, then perform quick freezing to prepare frozen shrimps, and observe the color of the shrimps after deep-frozen storage at -23~-12°C for one year. The loss of shrimp juice did not increase significantly during thawing and heating, and the original flavor and taste were maintained.

[0021] Table 2 Effect of adding antifreeze agent on thawing loss rate of frozen shrimp

[0022]

Embodiment 3

[0024] The aqueous solution system of the frozen shrimp antifreeze of the present embodiment includes the following mass concentration components: low acyl gellan gum 0.25%; trehalose 1.8%; sodium lactate 2.5%; sodium citrate 1.0%; sodium ascorbate 0.6%, wherein The molecular weight of low acyl gellan gum is 0.5×10 5 Da.

[0025] When preparing, just weigh the above components and dissolve them in deionized water. Use the configuration solution to soak the shrimps for 8 to 12 hours, then perform quick freezing to prepare frozen shrimps, and observe the color of the shrimps after deep freezing at -23 to -12°C for two years. No change, the loss of shrimp juice did not increase significantly when thawing and heating, and the original flavor and taste were maintained.

[0026] Table 3 Effect of adding antifreeze agent on thawing loss rate of frozen shrimp

[0027]

[0028]

[0029] Each component of the antifreeze agent of the present invention is described in detail below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com