Preparation method and application of high-sulfur content carbon and sulfur lithium ion battery material

A technology of lithium-ion batteries and ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery cycle performance, poor conductivity of lithium sulfide, and internal resistance of corroded batteries, so as to improve specific capacity and cycle Performance, high specific capacity, full and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

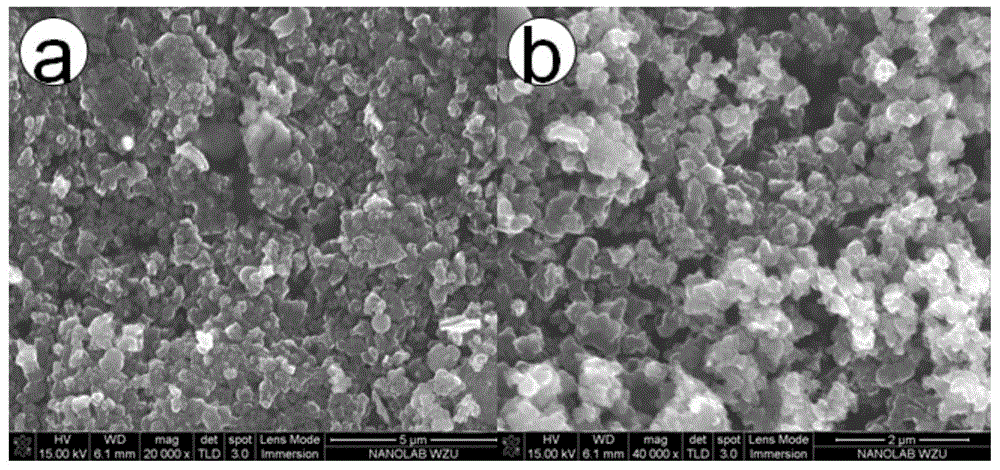

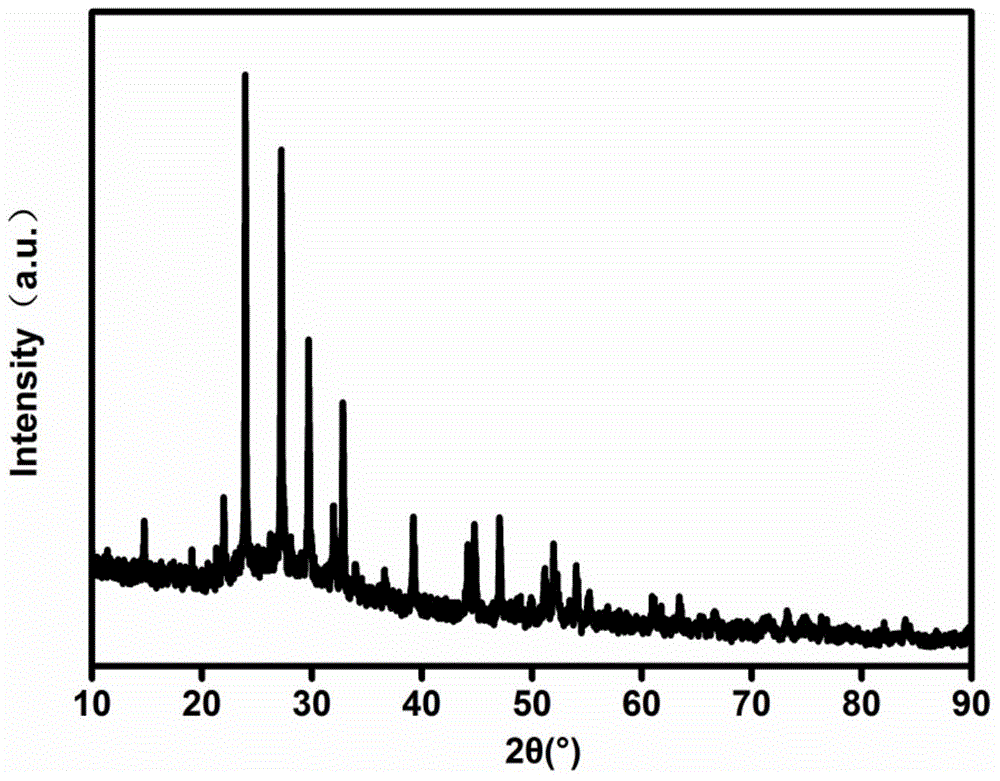

[0024] Embodiment 1. High sulfur content novel carbon-sulfur molecular material initial product

[0025] Accurately weigh 2g of elemental sulfur, add it to a 100ml stainless steel autoclave, measure 12ml of hexachlorobutadiene (20g) with a graduated cylinder, slowly add it to the stainless steel autoclave containing elemental sulfur, and cover the lid of the autoclave , After making sure that it is tightened, pour in 1MPa protective gas argon, and use an oven to raise the temperature to 100°C for 1 hour. After the reaction, cool down to room temperature naturally, open the reaction kettle, collect the black product in the kettle into a 50ml centrifuge tube with a straw, centrifuge at 8000r / min for 15 minutes, absorb the upper yellow liquid, and add absolute ethanol to the centrifuge tube Centrifuge, repeat 3 times, discard the supernatant and then add ethanol aqueous solution with a volume concentration of 50% to centrifuge, repeat 3 times, finally discard the supernatant and ...

Embodiment 2

[0026] Embodiment 2. High sulfur content novel carbon-sulfur molecular material initial product

[0027] Accurately weigh 2g of elemental sulfur, add it to a 100ml stainless steel autoclave, measure 24ml of hexachlorobutadiene (40g) with a graduated cylinder, slowly add it to the stainless steel autoclave containing elemental sulfur, and cover the lid of the autoclave , After making sure that it is tightened, pour in 5MPa protective gas argon, and use an oven to heat up to 150°C for 20h. After the reaction, cool down to room temperature naturally, open the reaction kettle, collect the black product in the kettle into a 50ml centrifuge tube with a straw, centrifuge at 8000r / min for 15 minutes, absorb the upper yellow liquid, and add absolute ethanol to the centrifuge tube Centrifuge, repeat 3 times, discard the supernatant and then add ethanol aqueous solution with a volume concentration of 50% to centrifuge, repeat 3 times, finally discard the supernatant and add absolute etha...

Embodiment 3

[0028] Embodiment 3. High sulfur content novel carbon-sulfur molecular material primary product

[0029] Accurately weigh 2g of elemental sulfur, add it to a 100ml stainless steel autoclave, measure 36ml of hexachlorobutadiene (60g) with a graduated cylinder, slowly add it to the stainless steel autoclave containing elemental sulfur, and cover the lid of the autoclave , After making sure that it is tightened, pour in 10MPa protective gas argon, and use an oven to heat up to 200°C for 20h. After the reaction, cool down to room temperature naturally, open the reaction kettle, collect the black product in the kettle into a 50ml centrifuge tube with a straw, centrifuge at 8000r / min for 15 minutes, absorb the upper yellow liquid, and add absolute ethanol to the centrifuge tube Centrifuge, repeat 3 times, discard the supernatant and then add ethanol aqueous solution with a volume concentration of 50% to centrifuge, repeat 3 times, finally discard the supernatant and add absolute eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com