A method for preparing ion-exchange fibers by ultraviolet light grafting

An ion exchange fiber and ultraviolet light technology, which is applied in the field of ultraviolet light grafting to prepare ion exchange fibers, can solve the problems of no application value, large reaction space, low maximum adsorption capacity, etc., achieve the characteristics of efficient adsorption of heavy metal ions, overcome the dark light District, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

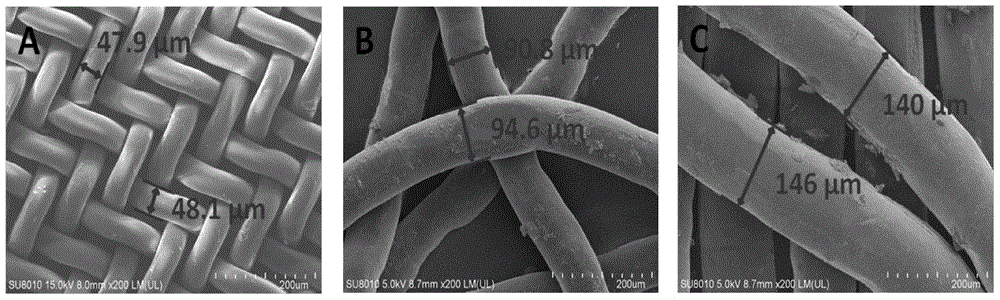

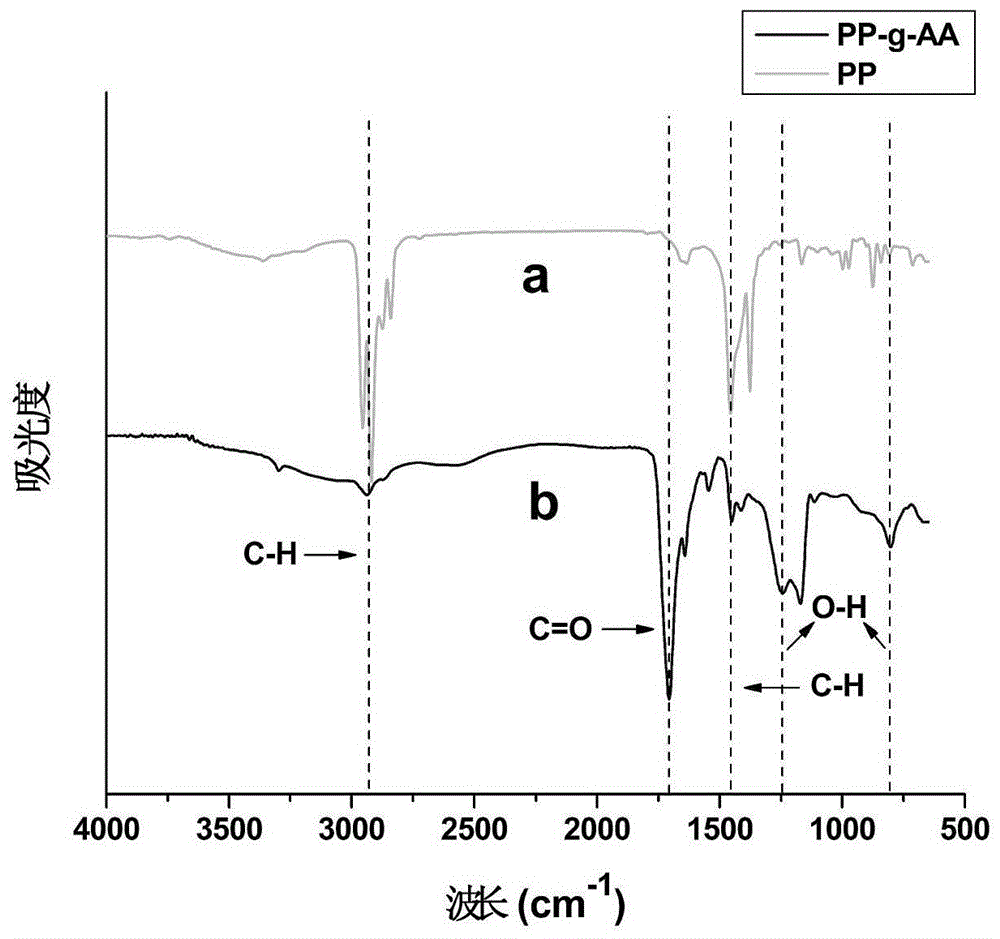

[0033] Cut a piece of polypropylene mesh with an appropriate size, soak it in a 10% benzophenone-acetone solution, take it out after 30 minutes, and let it dry naturally in the dark; then, add 25mL of 0.1mol / L benzophenone to the quartz tube Sulfuric acid solution, then measure 5mL of acrylic acid monomer (accounting for 16.67% by volume) into the above-mentioned quartz tube and mix evenly, then add a certain amount of polymerization inhibitor (its mass concentration is 5.0g / L), dissolve After completion, put the dried polypropylene mesh vertically into the quartz tube, and pass nitrogen gas for 15 minutes; after that, fix the quartz tube with the mechanical rotor, control the speed at 80-100r / min, and turn on the high-pressure mercury lamp at the same time Carry out light reaction; after reacting for 60 minutes, take out the reaction product, wash it with hot water, and finally extract it with acetone for 12 hours and dry it to obtain an ion exchange fiber grafted with carboxy...

Embodiment 2

[0036] Cut a piece of polypropylene mesh with an appropriate size, soak it in a solution of 25% benzophenone-acetone, take it out after 15 minutes, and let it dry naturally in the dark; then, add 26 mL of 0.2 mol / L benzophenone to the quartz tube Sulfuric acid solution, then measure 4mL of acrylic acid monomer (accounting for 13.33% by volume) into the above-mentioned quartz tube and mix evenly, then add a certain amount of polymerization inhibitor (its mass concentration is 3g / L), and dissolve completely Finally, put the dried polypropylene mesh vertically into the quartz tube, and pass nitrogen gas for 15 minutes; after that, fix the quartz tube with the mechanical rotor, control the speed at 80-100r / min, and at the same time, turn on the high-pressure mercury lamp for Light reaction; after 120 minutes of reaction, the reaction product was taken out, washed with hot water, and finally extracted with acetone for 12 hours and dried to obtain ion exchange fibers grafted with car...

Embodiment 3

[0041] Cut a piece of polypropylene mesh with an appropriate size, soak it in a 30% benzophenone ethanol solution, take it out after 10 minutes, and let it dry naturally in the dark; then, add 28 mL of benzophenone with a concentration of 0.4 mol / L to the quartz tube hydrochloric acid solution, and then measure 2mL of acrylic acid monomer (accounting for 5% by volume) into the above-mentioned quartz tube and mix evenly, then add a certain amount of polymerization inhibitor (its mass concentration is 1.5g / L), dissolve After completion, put the dried polypropylene mesh vertically into the quartz tube, and pass nitrogen gas for 15 minutes; after that, fix the quartz tube with the mechanical rotor, control the speed at 80-100r / min, and turn on the high-pressure mercury lamp at the same time Carry out light reaction; after reacting for 30 minutes, take out the reaction product, wash it with hot water, and finally extract it with acetone for 12 hours and dry it to obtain an ion excha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com