A kind of preparation method of silicon hydrogen compound

A technology for silicon hydride compounds and chlorosilanes, applied in the direction of silicon organic compounds, etc., can solve problems such as hindering the use of such compounds, high price of silicon hydride compounds, harsh preparation methods, etc., which is beneficial to laboratory preparation and industrial production. High temperature and high pressure reaction, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of silicon hydrogen compound, comprises steps as follows:

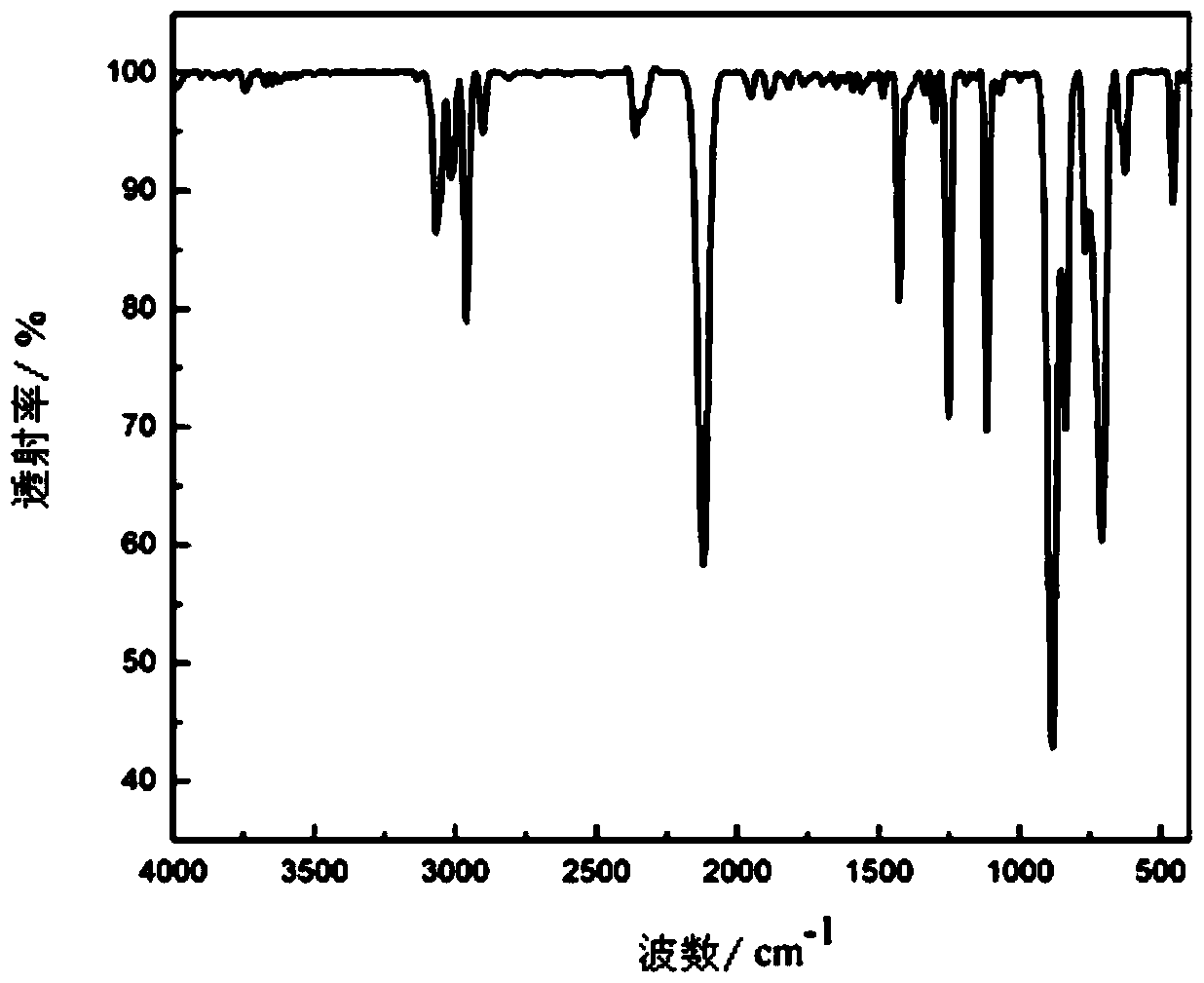

[0028] (1) In a four-necked round-bottomed flask equipped with a spherical condenser, a thermometer, a constant pressure dropping funnel and a T-type three-way piston, put 1.33g of magnesium chips, and mix 7.85g of phenyldimethylsilyl chloride and 6.63 The mixed solution of g tetrahydrofuran (THF) was slowly added dropwise to magnesium chips, heated to 80°C under the protection of Ar gas atmosphere, and reacted at 80°C with a stirring speed of 10r / min for 24 hours. Cool naturally to room temperature under the protection of atmosphere to obtain an intermediate reaction product;

[0029] (2) At a stirring speed of 10r / min, slowly add H to the intermediate reaction product at a rate of 3 drops per second. 3 o + solution, dropwise added H 3 o + H in solution 3 o + The molar amount of phenyldimethylsilane is equal to that of phenyldimethylsilane, filtered, the filtrate is extracted...

Embodiment 2

[0031] A kind of preparation method of silicon hydrogen compound, comprises steps as follows:

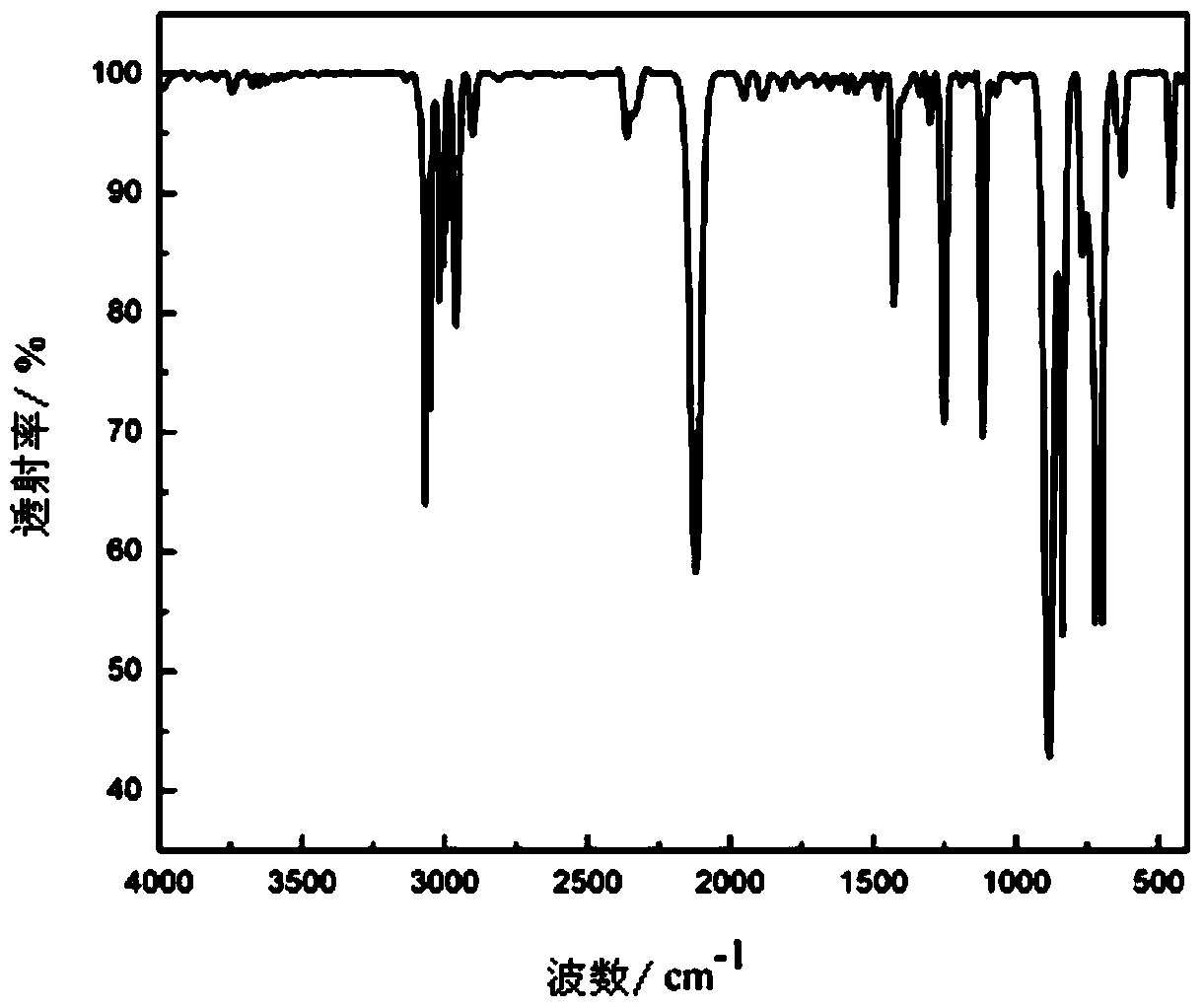

[0032] (1) In a four-neck round bottom flask equipped with a spherical condenser, a thermometer, a constant pressure dropping funnel and a T-shaped three-way piston, put 1.18g of magnesium chips, and mix 9.52g of diphenylmethylchlorosilane and 14.66 The mixed solution of g hexamethylphosphoric triamide (HMPA) was slowly added dropwise to magnesium chips, heated to 90°C under the protection of Ar gas atmosphere, and reacted at 90°C with a stirring speed of 15r / min for 20 hours. After completion, naturally cool to room temperature under the protection of Ar gas atmosphere to obtain an intermediate reaction product;

[0033] (2) At a stirring speed of 15r / min, slowly add H to the intermediate reaction product at a rate of 4 drops per second. 3 o + solution, dropwise added H 3 o + H in solution 3 o + The molar amount of diphenylmethylsilane is equal to that of diphenylmethylchloro...

Embodiment 3

[0035] A kind of preparation method of silicon hydrogen compound, comprises steps as follows:

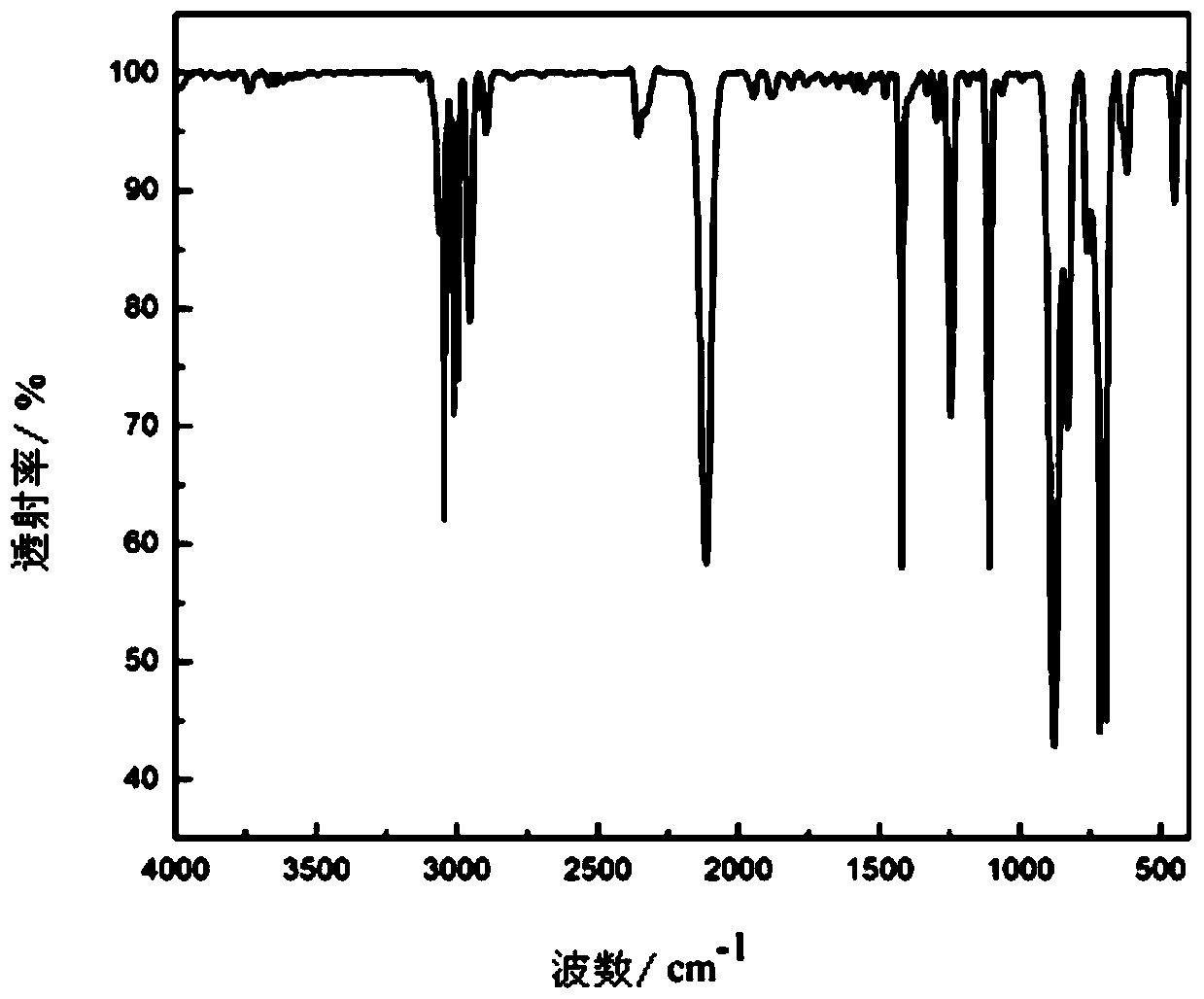

[0036] (1) In a four-neck round-bottom flask equipped with a spherical condenser, a thermometer, a constant pressure dropping funnel and a T-shaped three-way piston, put 0.45g of magnesium powder, add 4.60g of triphenylchlorosilane to 4.05g of tetrahydrofuran (THF) and hexamethylphosphoric triamide (HMPA) in the mixed solution, obtain mixture, the mass ratio of tetrahydrofuran (THF) and hexamethylphosphoric triamide (HMPA) in the mixed solution is: 2.5:1, will The mixture was slowly added dropwise to the heated magnesium powder, heated to 90°C under the protection of Ar gas atmosphere, and reacted at 90°C with a stirring speed of 16r / min for 20 hours. Cool to room temperature to obtain an intermediate reaction product;

[0037] (2) At a stirring speed of 16r / min, slowly add H to the intermediate reaction product at a rate of 5 drops per second. 3 o + solution, dropwise added H 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com