A Mechanochemical Vulcanization Treatment Method for Waste CRT Cone Glass

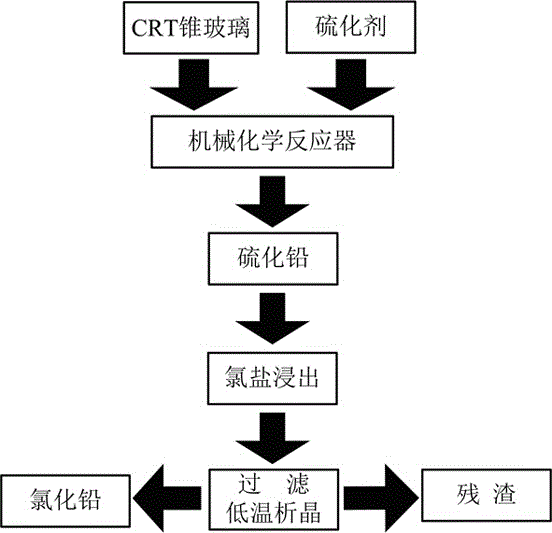

A mechanochemical and vulcanization treatment technology, which is applied in the direction of grain treatment, lead halide, process efficiency improvement, etc., can solve the problems of difficult to realize industrialization and inapplicability, and achieve the effect of high vulcanization efficiency, wide application and mature process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 4 grams of waste cathode ray tube cone glass and sodium sulfide compound (according to the molar ratio of lead in the cone glass to sulfur in the vulcanizing agent 1:1.2) into the planetary ball mill ball mill jar, and then add stainless steel balls to the ball mill jar (where 24 pieces of Φ 9.6mm, 100 pieces of Φ5.6mm stainless steel grinding balls), the mass ratio of material to grinding balls is 1:80, and then filled with nitrogen or helium to maintain an inert environment and seal. Set the rotational speed of the ball mill to 250 rpm, the ball milling time to 1 hour, the ball milling mode to run for 15 minutes, stop for 15 minutes, and cycle in turn. After the mechanochemical ball milling reaction, samples were taken to analyze and test the vulcanization rate of lead in the cone glass.

[0021] After analysis, the sulfuration rate of metal lead in the CRT cone glass is 62%.

Embodiment 2

[0023] Add 4 grams of waste cathode ray tube cone glass and sodium sulfide mixture (according to the molar ratio of lead in the cone glass to sulfur in the vulcanizing agent 1:1.2) into the ball mill jar of the planetary ball mill, and then add stainless steel balls (24 of them) to the ball mill jar Φ9.6mm, 100 Φ5.6mm stainless steel grinding balls), the mass ratio of material to grinding balls is 1:80, and then filled with nitrogen or helium to maintain an inert environment and seal. Set the rotating speed of the ball mill to 550 rpm, the ball milling time to 2 hours, the ball milling mode to run for 15 minutes, stop for 15 minutes, and then cycle in turn. After the mechanochemical ball milling reaction, samples were taken to analyze and test the vulcanization rate of lead in the cone glass.

[0024] After analysis, the sulfuration rate of metal lead in the CRT cone glass is 73%.

Embodiment 3

[0026] Add 4 grams of waste cathode ray tube cone glass and vulcanizing agent mixture (according to the molar ratio of lead in the cone glass to sulfur in the vulcanizing agent 1:2.0) into the ball milling tank of the planetary ball mill, and then add stainless steel balls (of which 24 Φ9.6mm, 100 Φ5.6mm stainless steel grinding balls), the mass ratio of material to grinding balls is 1:80, and then filled with nitrogen or helium to maintain an inert environment and seal. Set the rotational speed of the ball mill to 550 rpm, the milling time to 1 hour, the ball milling mode to run for 15 minutes, stop for 15 minutes, and then cycle in turn. After the mechanochemical ball milling reaction, samples were taken to analyze and test the vulcanization rate of lead in the cone glass.

[0027] After analysis, the sulfuration rate of metal lead in the CRT cone glass is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com