Preparation method of nitrogen doped loaded Bi203/Si02 light catalyst

A photocatalyst and supported technology, which is applied in the field of preparation of nitrogen-doped supported Bi2O3/SiO2 photocatalysts, which can solve the problems of easy agglomeration, inability to fully demonstrate the catalytic ability, and reduce the visible light catalytic activity of the catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

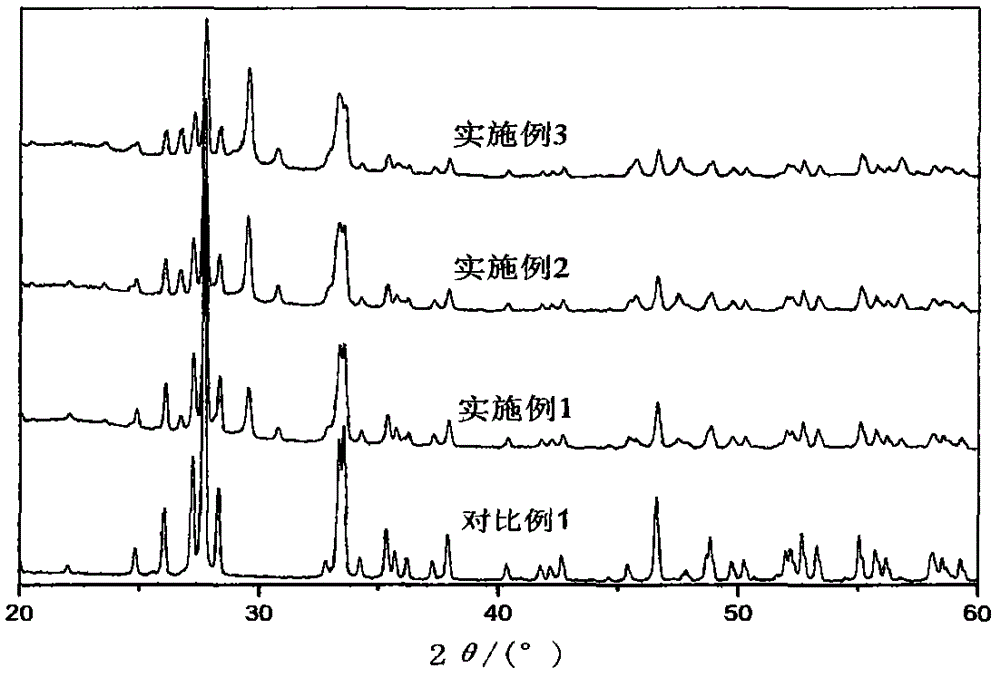

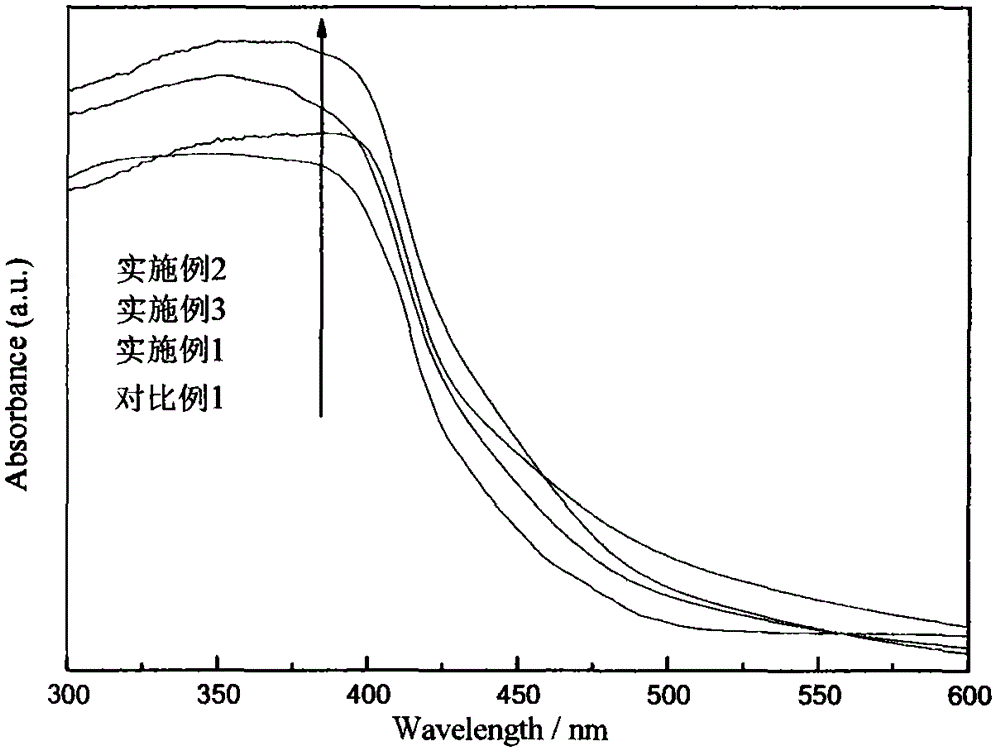

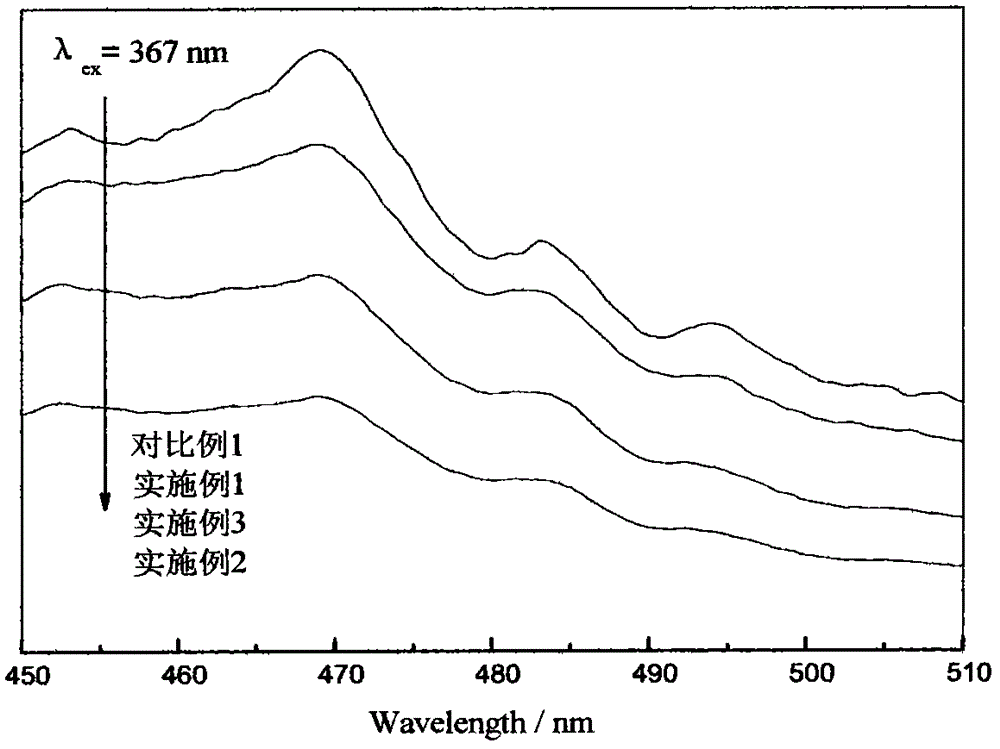

[0029] The embodiment of the invention discloses a nitrogen-doped load type Bi 2 O 3 / SiO 2 The preparation method of the photocatalyst includes the following steps: step a) the macroporous SiO 2 Put it in bismuth nitrate solution, keep it warm at 70~90℃ after soaking, then airtight NH at 55~60℃ 3 ·H 2 React in O atmosphere, soak in dilute ammonia water after being placed to obtain intermediate product, namely Bi(OH) 3 / SiO 2 Visible light catalyst; step b) CO(NH 2 ) 2 Placed in bismuth nitrate solution to obtain a mixed solution, the mixed solution is added dropwise to the intermediate product, the NH sealed at 55-60 ℃ 3 ·H 2 React in O atmosphere, soak in dilute ammonia water, wash, dry and calcinate at high temperature to obtain nitrogen-doped supported Bi 2 O 3 / SiO 2 catalyst of light.

[0030] As a preferred solution, the macroporous SiO 2 Prepare according to the following method: mix epoxy resin, polyethylene glycol 1000 and polyethylene glycol 2000, and then add the curing ...

Embodiment 1

[0050] Add 20g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 25g ethylene glycol to prepare a high-concentration solution, 25g acetonitrile diluent was added, and the prepared macroporous SiO 2 The carrier is placed in the solution and taken out after being fully immersed to obtain the reaction product and the first mixed solution respectively; the reaction product is kept at 80°C for 2h, and then placed in a closed NH 3 ·H 2 React at 60°C for 2h in O atmosphere. Take out the sample and place it at room temperature for 1 hour, and then soak it in 1M dilute ammonia water for 1.5 hours to fully carry out the hydrolysis and obtain the intermediate product;

[0051] Then take 2.48g of urea and dissolve it in the first mixed solution, control the molar ratio of N to Bi to 1.0 to obtain a second mixed solution, and add the second mixed solution dropwise to the intermediate product with a rubber tip dropper. Until the absorption is sufficient, then in the airtight NH 3 ·H 2 React at 55°C for 1.5h...

Embodiment 2

[0053] 25g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 30g ethylene glycol to prepare a high-concentration solution, 25g acetonitrile diluent was added, and the prepared macroporous SiO 2 The carrier is placed in the solution and taken out after being fully immersed to obtain the reaction product and the first mixed solution respectively; the reaction product is kept at 80°C for 2h, and then placed in a closed NH 3 ·H 2 React at 60°C for 2h in O atmosphere. Take out the sample and place it at room temperature for 1 hour, and then soak it in 1 mol / L dilute ammonia water for 1.5 hours to fully carry out the hydrolysis and obtain the intermediate product;

[0054] Then take 6.19g of urea and dissolve it in the first mixed solution, control the molar ratio of N to Bi to 2.0, add the mixed solution dropwise to the above intermediate product with a rubber tip dropper until the absorption is sufficient, and then seal it NH 3 ·H 2 React at 55°C for 2h in O atmosphere. Take out the sample and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com