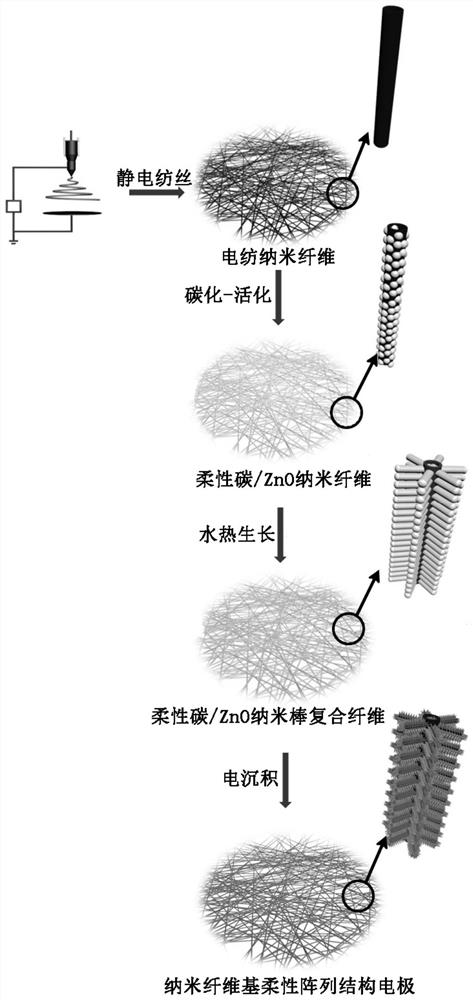

A nanofiber-based flexible array electrode and its preparation method

A nanofiber, array structure technology, applied in the field of electrochemical materials, can solve the problems of poor fastness, cumbersome and time-consuming growth process, uneven loading of ZnO seed crystals, etc., and achieves the effect of simple process, improved overall capacitance performance, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a nanofiber-based flexible array structure electrode, including the following steps:

[0028] Step a, uniformly disperse polyacrylonitrile, purified terephthalic acid and acidified carbon nanotubes in 5mL of N,N-dimethylformamide, stir magnetically at a constant temperature at 60°C until the dispersion is uniform, and use it as the inner layer spinning solution, The concentration of polyacrylonitrile in the inner layer spinning solution is 6.0wt%, the concentration of purified terephthalic acid is 5.0wt%, and the concentration of acidified carbon nanotubes is 2.0wt%; Polyvinylpyrrolidone, zinc acetate and purified terephthalic acid Diformic acid is dispersed in 5mL of N, N-dimethylformamide, magnetically stirred at a constant temperature of 60°C until the dispersion is uniform, and used as the outer layer spinning solution. The concentration of polyvinylpyrrolidone in the outer layer spinning solution is 12wt%, zinc acetate...

Embodiment 2

[0034] This embodiment provides a method for preparing a nanofiber-based flexible array structure electrode, including the following steps:

[0035] Step a, uniformly disperse polyacrylonitrile, purified terephthalic acid and acidified carbon nanotubes in 8mL of N,N-dimethylformamide, stir magnetically at a constant temperature at 60°C until the dispersion is uniform, and use it as the inner layer spinning solution, The concentration of polyacrylonitrile in the inner layer spinning solution is 5.0wt%, the concentration of purified terephthalic acid is 5.0wt%, and the concentration of acidified carbon nanotubes is 0.5wt%; Polyvinylpyrrolidone, zinc acetate and purified terephthalic acid Diformic acid was dispersed in 10mL of N,N-dimethylformamide, stirred with a constant temperature magnetic force at 60°C until the dispersion was uniform, and used as the outer layer spinning solution. The concentration of polyvinylpyrrolidone in the outer layer spinning solution was 20.0wt%, ace...

Embodiment 3

[0041] This embodiment provides a method for preparing a nanofiber-based flexible array structure electrode, including the following steps:

[0042] Step a, uniformly disperse polyacrylonitrile, purified terephthalic acid and acidified carbon nanotubes in 6mL of N,N-dimethylformamide, stir magnetically at a constant temperature at 60°C until the dispersion is uniform, and use it as an inner layer spinning solution, The concentration of polyacrylonitrile in the inner layer spinning solution is 4.0wt%, the concentration of purified terephthalic acid is 3.0wt%, and the concentration of acidified carbon nanotubes is 1.5wt%; Polyvinylpyrrolidone, zinc acetate and purified terephthalic acid Diformic acid was dispersed in 5mL of N,N-dimethylformamide, stirred with a constant temperature magnetic force at 60°C until the dispersion was uniform, and used as the outer layer spinning solution. The concentration of polyvinylpyrrolidone in the outer layer spinning solution was 10.0wt%, aceti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com