A kind of photolysis oxidative fission VOC treatment device

A treatment device and photolysis technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of low removal efficiency, complex structure of the device, high maintenance cost, etc., and achieve improved treatment effect, sufficient light receiving, and maintenance low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like figure 1 As shown, the VOC waste gas treatment device includes a reaction box 1, an air inlet 2, a catalyst layer 3, an ultraviolet lamp 4, a VOC content detector 5, an air outlet 6, and the air inlet 2 is arranged on the lower left of the reaction box 1 side, the catalyst layer 3 is arranged above the air inlet 2, each ultraviolet lamp 4 is arranged above the corresponding catalyst layer 3, and the gas outlet 6 is arranged on the upper right of the reaction box 1, which is higher than the catalyst layer 3, and the gas outlet Set VOC content detector 5. In the experiment, 563mg / m of VOC gas was introduced 3 and heavy metal industrial waste gas, turn on the ultraviolet lamp 4 to irradiate for 10 minutes, after the treatment is completed, measure the remaining VOC content through the VOC content detector at the gas outlet 6, and the actual treatment air volume is 3700M 3 / H, dwell time 3 seconds.

[0034] Preparation of catalyst layer:

[0035] 1) TiO 2 Preparat...

Embodiment 2-10

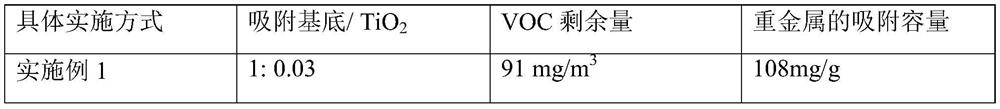

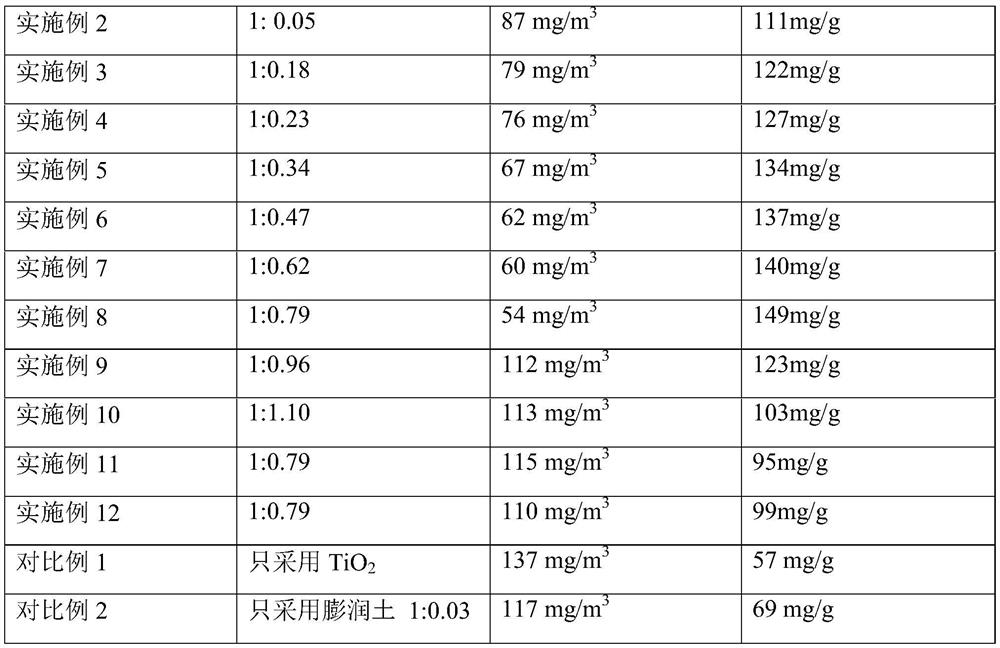

[0040] Adsorption substrate / TiO according to Table 1 2 The loading of catalyst is carried out, and treatment method and treatment air volume are all identical with embodiment 1, and the VOC remaining amount that obtains finally is as shown in table 1 below.

Embodiment 11

[0042] Other conditions are the same as in Example 8, except that the preparation of the adsorption substrate does not use temperature programming, but directly heats the mixture of bentonite and chitosan to 450 ° C for 2 hours to prepare a carbon / bentonite composite material as an adsorption base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com