Condensate oil deodorization method

A technology for condensate and deodorization, applied in the petroleum industry, refining hydrocarbon oil, refining with halogen compounds, etc., can solve the problems affecting the processing of condensate, loss of extraction solvent, difficulty in lye separation, etc., and reduce desulfurization sewage. , long-lasting deodorization effect, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

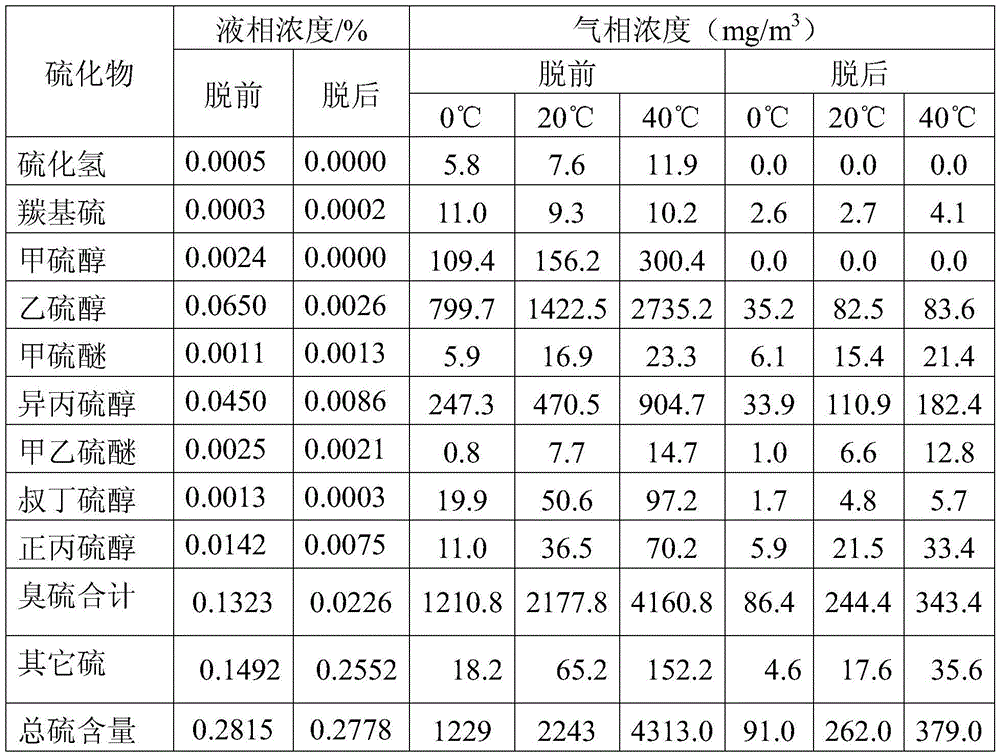

[0047] The reactor was filled with activated carbon-supported sulfonated cobalt phthalocyanine catalyst (sulfonated cobalt phthalocyanine accounted for 0.5% of the total mass of the catalyst), the filling volume was 20 mL, and the filling height-diameter ratio was 6:1; the activator was ammonia, methanol, and methylal. Aqueous solution, in which the mass ratio between ammonia, methanol, methylal, and water = 10:15:5:70, air is the oxidant; condensate A, activator, and air are mixed in a mixer, and the gas-liquid adopts a filter element Mixing method, liquid-liquid adopts pipeline mixing method, the flow rate of condensate oil is 200mL / h, the flow rate of activator is 8μL / h, and the air injection rate is 200mL / h; the condensate oil A, activator and air are mixed and then enter the reactor to contact with the catalyst , the bottom-in and top-out feeding mode, the pressure of the reactor is 0.105MPa, the top of the reactor is equipped with a vent valve to release excess gas, and t...

Embodiment 2

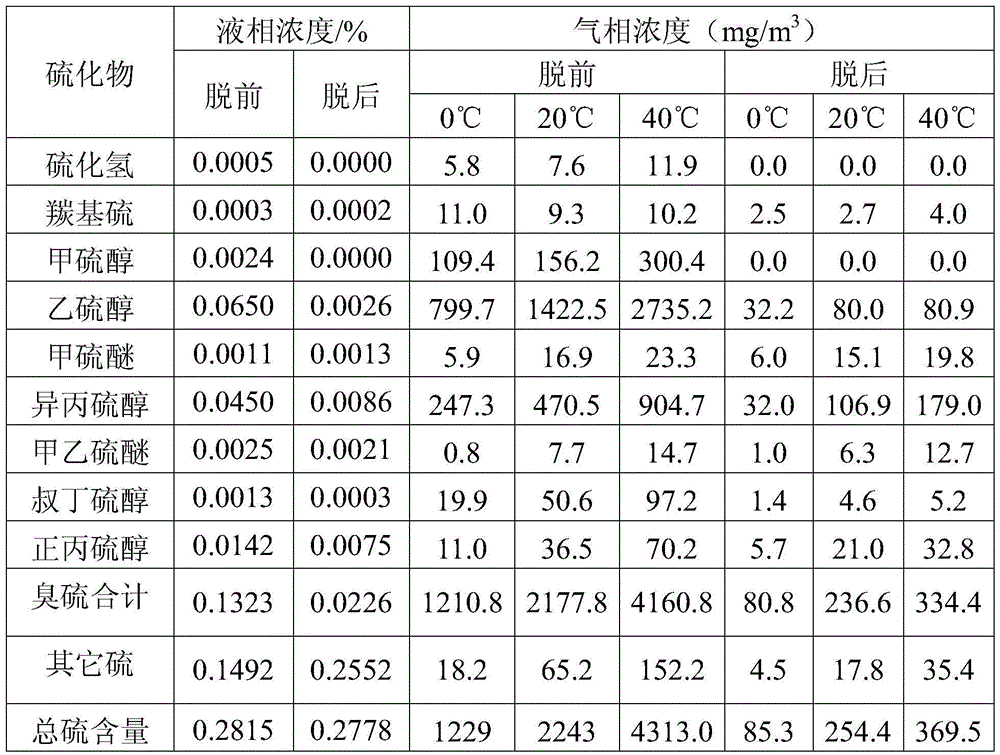

[0051] The reactor was filled with activated carbon-supported sulfonated cobalt phthalocyanine catalyst (sulfonated cobalt phthalocyanine accounted for 0.5% of the total catalyst mass), the filling volume was 20 mL, and the filling height-diameter ratio was 6:1; the activator was hexadecyl-trimethyl An aqueous solution of ammonium hydroxide, ethanol and diethylene glycol monomethyl ether, wherein the mass ratio between cetyl-trimethylammonium hydroxide, ethanol, diethylene glycol monomethyl ether and water=12:13: 5:70, air is the oxidant; the condensate A, the activator and the air are mixed in the mixer, the gas-liquid adopts the filter element mixing method, the liquid-liquid adopts the pipeline mixing method, the condensate oil flow rate is 200mL / h, and the activator flow rate 12μL / h, the air injection volume is 200mL / h; the condensate A, activator and air are mixed and then enter the reactor to contact the catalyst. The pressure valve was pressed to release excess gas, and...

Embodiment 3

[0055] The reactor was filled with activated carbon-supported sulfonated cobalt phthalocyanine catalyst (sulfonated cobalt phthalocyanine accounted for 0.3% of the total mass of the catalyst), with a filling volume of 20 mL and a filling height-diameter ratio of 6:1; the activator was N,N-dimethyl- An aqueous solution of cetylammonium, isopropanol, and methylal, wherein the mass ratio between N,N-dimethyl-hexadecylammonium, isopropanol, methylal, and water=7:15: 6:72, the oxidant is 30% hydrogen peroxide; the condensate A, the activator and the oxidant are mixed in a mixer, the flow rate of the condensate oil is 200mL / h, the flow rate of the activator is 16μL / h, and the flow rate of the oxidant is 1.2mL / h, The condensate A, the activator and the oxidant are mixed and then enter the reactor to contact with the catalyst. The feed mode is top-in and bottom-out, and the temperature of the reactor is 12°C. The above-mentioned process conditions were used to treat the condensate oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com