High-thermal-resistance expandable polystyrene (EPS) composition particles and preparation method thereof

A technology of expandable polystyrene and polystyrene, which is applied in the field of flame-retardant expandable polystyrene composition particles, can solve the problems of reducing cell quality, easy shrinkage deformation, and lack of elasticity, etc. Good mechanical properties, saving process cost, raw material handling and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

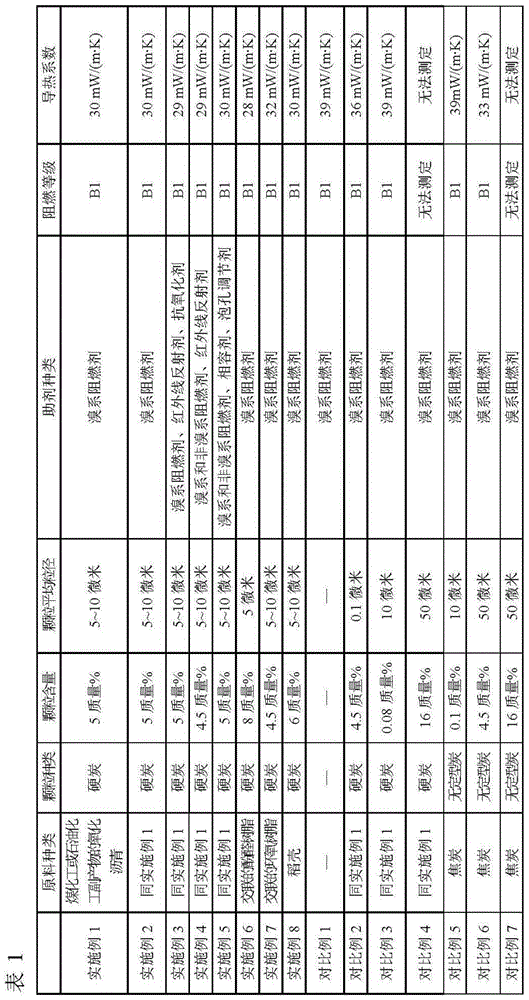

Examples

Embodiment 1

[0055] Put the oxidized asphalt, which is a by-product of coal chemical industry or petrochemical industry, into a tube furnace after pulverization, heat up to 250-350°C in an air atmosphere, and solidify it, then put the cured asphalt powder into a carbonization furnace, Under the atmosphere, the temperature is raised to 700-1300° C. for carbonization treatment to obtain pitch hard carbon particles. The pitch hard carbon particles are screened and decomposed, and the hard carbon particles of 5-10 microns are selected as infrared absorbers.

[0056] The general-purpose polystyrene GPPS (Mw=220000g / mol), the pentane blowing agent of 6 mass % content, the hexabromocyclododecane of 1.5 mass % content, the average particle diameter obtained by the above-mentioned sintering of 5 mass % is about 5~ 10 micron bituminous hard carbon particles.

[0057] At 200°C, continue to mix evenly in an extruder or static mixer, and the mixing time is controlled at 10 minutes;

[0058] Cool to 18...

Embodiment 2

[0064] As in Example 1, pitch hard carbon particles were prepared, and particles with an average particle size of 5-10 microns were selected as infrared absorbers.

[0065] General-purpose polystyrene GPPS (Mw=180000g / mol), the pentane blowing agent of 5 mass % content, the brominated styrene-butadiene-styrene block copolymer of 2.5 mass % content, 5 mass % above-mentioned 5-10 micron pitch hard carbon particles obtained by sintering. In an extruder at a temperature of 200°C, fully mix evenly, cool to 180-205°C, and then granulate into expandable black polystyrene composition particles with an average particle diameter of 1.0mm. The pre-foaming and molding boards were carried out as in Example 1, and the flame retardancy and thermal conductivity were tested.

[0066] The black expandable polystyrene composition particles containing pitch hard carbon particles have a flame retardant grade of B1 after foaming and a thermal conductivity of 30 mW / (m·K). The foamed sheet has fine...

Embodiment 3

[0068] As in Example 1, pitch hard carbon particles with an average particle size of 5-10 microns were prepared.

[0069] General-purpose polystyrene GPPS (Mw=280000g / mol), the pentane blowing agent of 6 mass % content, the brominated styrene-butadiene-styrene block copolymer of 1.5 mass % content, 5 mass % above-mentioned The bituminous hard carbon particle that sintering obtains, the hollow glass microsphere of the average particle diameter of 0.5 mass % content 30 microns, the polyphenylene ether (PPO) of 15 mass % content, 0.1 mass % commercially available antioxidant B225 (hindered phenol 1010 and phosphite 168 mixture). In a static mixer at a temperature of 220°C, fully mix evenly, cool to 180-215°C, and then granulate into black expandable polystyrene composition particles with an average particle diameter of 1.0 mm.

[0070] The expandable polystyrene composition particles are used in conventional pre-foaming and molding machine-made boards. Compared with traditional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com