Processing method of landfill leachate film concentrated solution

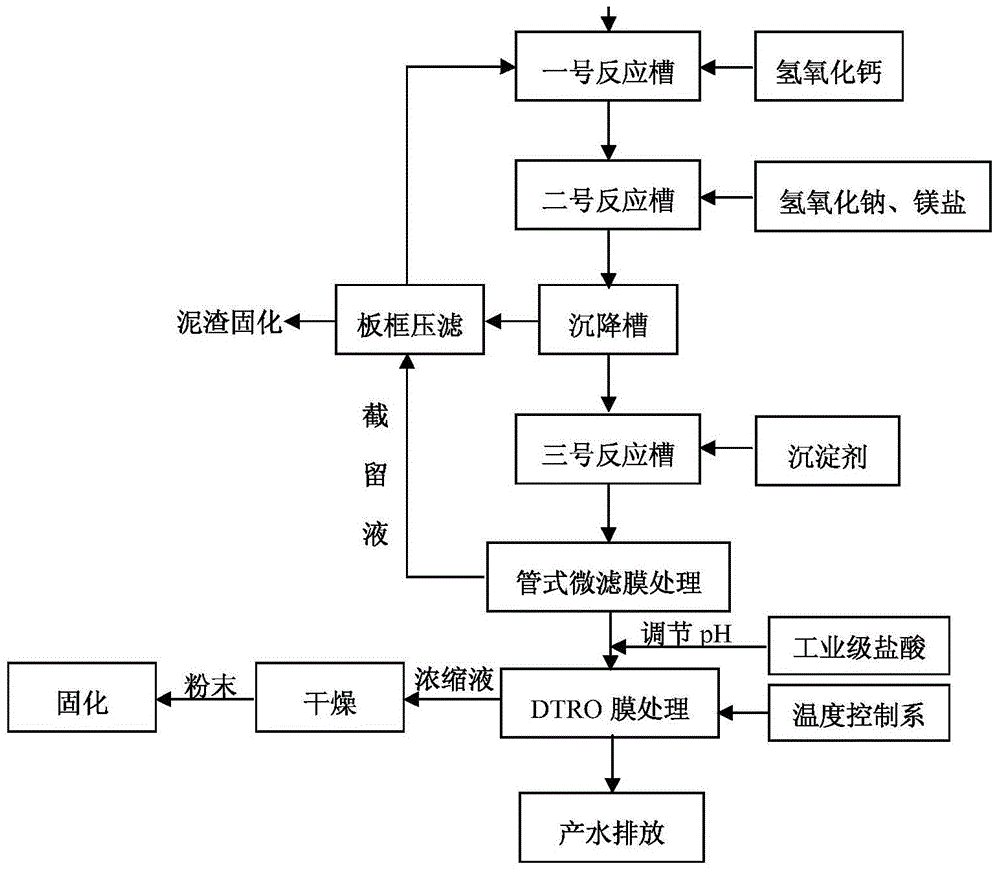

A technology of landfill leachate and treatment method, which is applied in the field of treatment of landfill leachate membrane concentrate, can solve the problems that the recovery efficiency cannot be further improved, the concentrate is not softened thoroughly, and scaling is easy to occur, so as to achieve strong practicability and reduce The probability of clogging and the effect of improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The combined process disclosed by the invention is used to treat the leachate membrane treatment concentrate of a waste incineration plant.

[0033] The CODcr concentration of the concentrated liquid after membrane treatment in the incineration plant is 1600mg / L, the total hardness content is 2000mg / L, the conductivity is 30000μs / cm, and the pH is 7.0.

[0034] (1) Get 5 tons of membrane treatment concentrated solution, add technical grade calcium hydroxide to the membrane treatment concentrated solution, adjust pH to be 10.5, obtain mixed solution;

[0035] (2) Sodium hydroxide is passed into the mixed solution of step (1), and the pH is controlled to be 11.5, and magnesium sulfate is added to obtain a mixed solution containing precipitation;

[0036](3) The mixed solution containing precipitation in step (2) is passed into the settling tank for precipitation to obtain 450L of high sedimentation liquid and supernatant with mud content, and then add soda ash in the supe...

Embodiment 2

[0043] The combined process disclosed by the invention is used to treat the leachate membrane treatment concentrate of a landfill site.

[0044] The CODcr concentration of the concentrated liquid after membrane treatment in the landfill is 1100mg / L, the total hardness content is 3200mg / L, the conductivity is 28900μs / cm, and the pH is 7.0.

[0045] (1) Get 5 tons of membrane treatment concentrated solution, add technical grade calcium hydroxide to the membrane treatment concentrated solution, adjust pH to be 10.5, obtain mixed solution;

[0046] (2) Sodium hydroxide is passed into the mixed solution of step (1), and the pH is controlled to be 11.5, and magnesium sulfate is added to obtain a mixed solution containing precipitation;

[0047] (3) The mixed solution containing precipitation in step (2) is passed into the settling tank for precipitation to obtain 450L of high sedimentation liquid and supernatant with mud content, and then add soda ash in the supernatant to make the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com