Method for treating fluosilicate waste residues

A treatment method, fluorosilicate technology, applied in the direction of alkali metal fluoride, etc., can solve the problems of reducing the progress of the reaction, premature precipitation of sodium fluoride, and high content of impurities in crystals, so as to increase the reaction temperature and dissolution amount increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

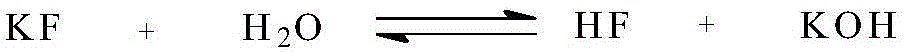

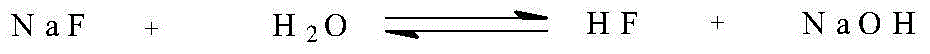

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Analysis of waste residue containing SiF 6 2- The total content is 57%, take 1 ton of waste residue, mix the waste residue and water in a ratio of 1:30, stir and heat up to 90°C, add 0.578 tons of sodium hydroxide (the excess coefficient ratio is 0.90, and make about 4 tons of aqueous solution ), stirring and reacting until the reaction is complete (pH is 7.1), a small amount of the reaction solution is dropped on the filter paper, it is colorless, and a 1% potassium permanganate aqueous solution is added until the reaction solution is just purple-red. Then in the reaction solution, add oxalic acid with a concentration of 10% to MnO 4 - The fuchsia has just faded. Keep the temperature at 90-100°C and perform hot filtration for the first time. Evaporate and concentrate the filtrate of the first hot filtration by 20 times, cool and crystallize at room temperature, and filter for the second time. The filter cake filtered for the second time was washed with saturated a...

Embodiment 2

[0057] Analysis of waste residue containing SiF 6 2- The total content is 62%, take 1 ton of waste residue, mix the waste residue and water in a ratio of 1:35, stir and heat up to 95°C, add 0.761 tons of sodium hydroxide (the excess coefficient ratio is 1.09, and make about 4 tons of aqueous solution ), stirring the reaction, until the reaction is complete (pH is 9.8), take a small amount of reaction solution and drop it on the filter paper, purple red, in the reaction solution, adding concentration is 10% oxalic acid to MnO 4 - The fuchsia has just faded. Keep the temperature at 90-100°C and perform hot filtration for the first time. Evaporate and concentrate the filtrate of the first hot filtration by 25 times, cool and crystallize at room temperature, and filter for the second time. The filter cake filtered for the second time was washed with saturated aqueous sodium fluoride solution and dried to obtain 0.932 tons of sodium fluoride product. The filtrate filtered for ...

Embodiment 3

[0059] Analysis of waste residue containing SiF 6 2- The total content is 66%, take 1 ton of waste residue, mix the waste residue and water in a ratio of 1:40, stir and heat up to 100°C, add 0.803 tons of sodium hydroxide (the excess coefficient ratio is 1.08, and make about 4 tons of aqueous solution ), stirring the reaction, until the reaction is complete (pH is 8.5), take a small amount of reaction solution and drop it on the filter paper, purple red, in the reaction solution, adding concentration is 10% oxalic acid to MnO 4 - The fuchsia has just faded. Keep the temperature at 90-100°C and perform hot filtration for the first time. Evaporate and concentrate the filtrate of the first hot filtration by 30 times, cool and crystallize at room temperature, and filter for the second time. The filter cake filtered for the second time was washed with saturated aqueous sodium fluoride solution and dried to obtain 0.975 tons of sodium fluoride product. The filtrate filtered for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com