Low-temperature lithium iron phosphate positive electrode material prepared by uniform coating using modified flash device and preparation method thereof

A flash evaporation device and a technology for lithium iron phosphate, which are applied in the field of low-temperature lithium iron phosphate positive electrode materials and their preparation, can solve the problems of cumbersome manufacturing processes, poor discharge performance, low electrical conductivity, etc., and achieve improved and consistent intrinsic electrical conductivity. High-quality, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

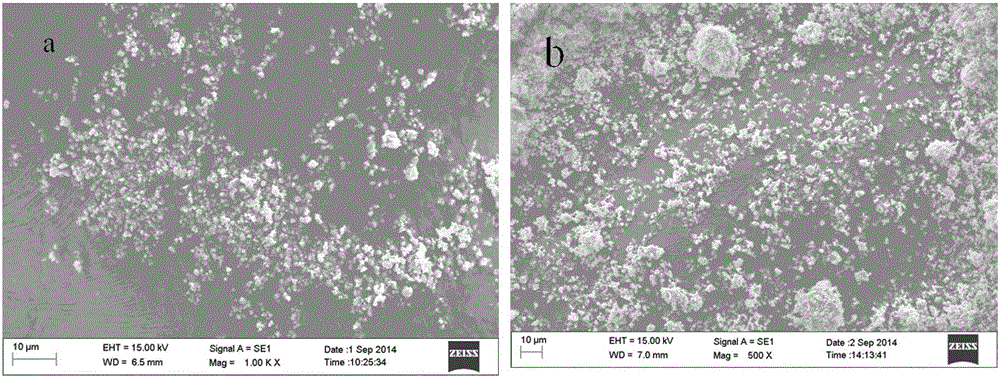

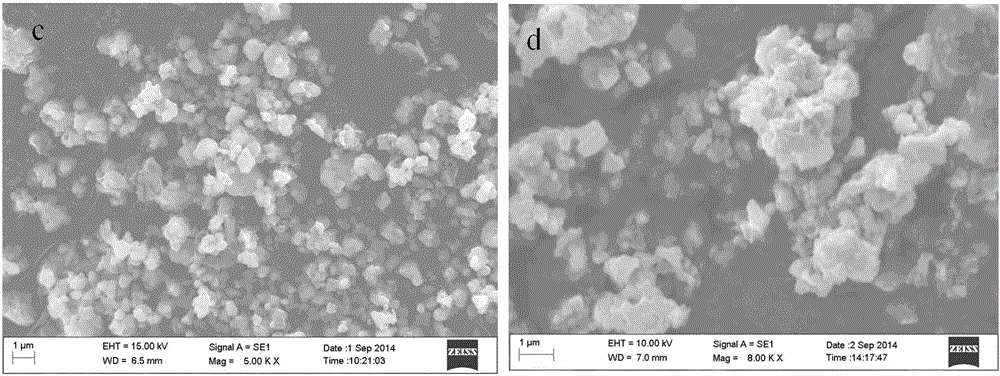

[0027] The invention as figure 1 , 2 As shown in , 3, a low-temperature lithium iron phosphate positive electrode material prepared by uniform coating using a modified flash device and its preparation method are characterized in that: the steps are as follows: (1) Preparation of iron manganese phosphate precursor: The phosphorus source, iron source, and manganese source are fully mixed according to the ratio of 1-1.02:0.8-0.9:0.2-0.1, and then pressed into tablets, then dewatered at 500-600°C and pre-calcined to obtain a manganese iron phosphate precursor; (2) Configure water or water-organic solvent mixed solution, dissolve the soluble raw materials corresponding to the elements to be coated in the above mixed solution in advance, and then weigh other reaction raw materials of lithium iron phosphate cathode material and manganese iron phosphate precursor in proportion, The reaction ratio of lithium source and manganese iron phosphate salt precursor is 1-1.05:1. After adding ...

Embodiment 1

[0030] A low-temperature lithium iron phosphate positive electrode material prepared by uniform coating using a modified flash device and its preparation method

[0031] Include the following steps:

[0032] (1) Preparation of iron manganese phosphate precursor:

[0033] Ammonium dihydrogen phosphate, ferrous oxalate, and manganese acetate are fully mixed at a ratio of 1.02:0.8:0.2, then pressed into tablets, and then dewatered at a high temperature of 500°C for 6 hours and pre-calcined to obtain a manganese iron phosphate precursor.

[0034] (2) Configure a water-ethanol mixed solution with a ratio of 1:0.2, and dissolve 0.125 times of glucose in the above mixed solution in advance; then weigh the lithium acetate and manganese iron phosphate precursors according to the ratio of 1.02:1, and add the above mixed solution Fully crush, stir and mix for 3 hours after neutralization to ensure complete and uniform mixing of materials.

[0035](3) Turn on the microwave source for 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com