Ultrasonic cleaning process for copper surface

An ultrasonic and copper surface technology, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of excessive foam, low conductivity, and inapplicability of ultrasonic cleaning, etc., and achieve strong decontamination ability , good anti-rust performance, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

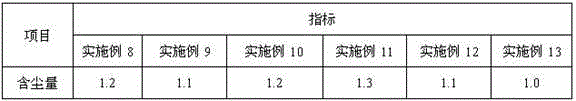

Examples

Embodiment 1

[0041] An ultrasonic cleaning process suitable for copper surfaces, the process steps are as follows:

[0042] 1) Pre-cleaning

[0043] Use hot dipping or spraying to soften, separate and dissolve the pollutants on the workpiece;

[0044] 2) rough washing

[0045] Under the action of water-based cleaning agent, ultrasonic cleaning will peel off the dirt on the surface of the workpiece;

[0046] 3) fine washing

[0047] Ultrasonic rinsing is used to wash off the residual cleaning medium on the surface of the workpiece with pure water;

[0048] 4) High pressure shower

[0049] High-pressure pure water spraying from top to bottom in all directions to wash the polluted medium in small blind holes and crevices, and dry with hot air;

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, on this basis:

[0052] The composition ratio of described water-based cleaning agent is as follows:

[0053] Surfactant KE-1 0.8g / l

[0054] Surfactant AES 2.0g / l

[0055] Surfactant NP-10 2.2 g / l

[0056] Sodium tripolyphosphate 0.5 g / l

[0057] Composite corrosion inhibitor 0.8 g / l

[0058] The solvent is water.

Embodiment 3

[0060] This embodiment is basically the same as Embodiment 1, on this basis:

[0061] The composition ratio of described water-based cleaning agent is as follows:

[0062] Surfactant KE-1 1.2 g / l

[0063] Surfactant AES 2.5 g / l

[0064] Surfactant NP-10 2.6 g / l

[0065] Zeolite 4A 0.6 g / l

[0066] Polyethylene and imidazoline 1 g / l

[0067] The solvent is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com