Preparation method for printing independent carbon nano tube thin film transistor in large area

A carbon nanotube thin film, thin film transistor technology, applied in nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., to achieve the effects of environmental friendliness, superior electrical performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

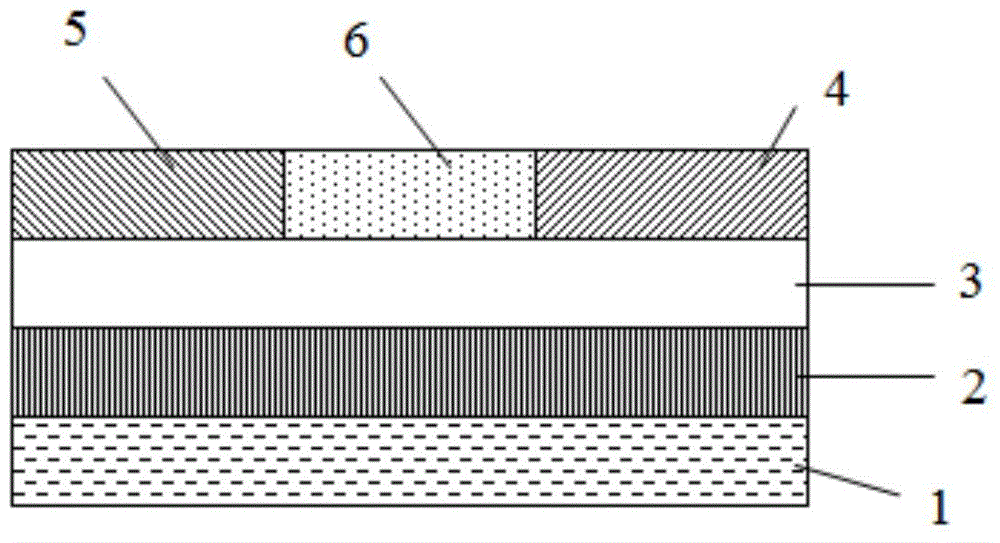

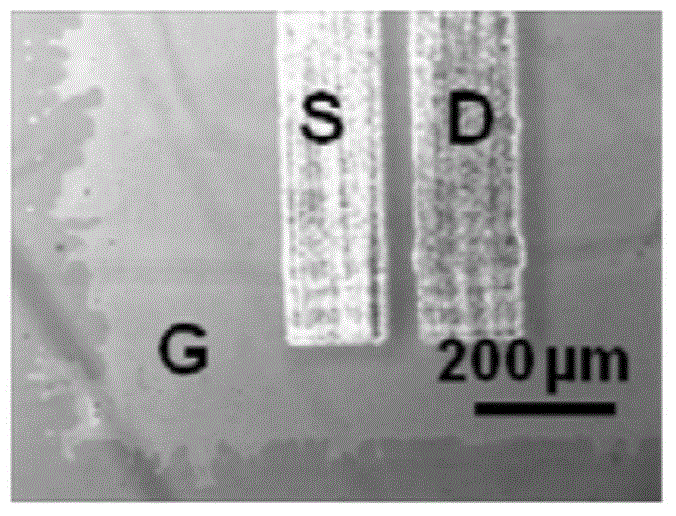

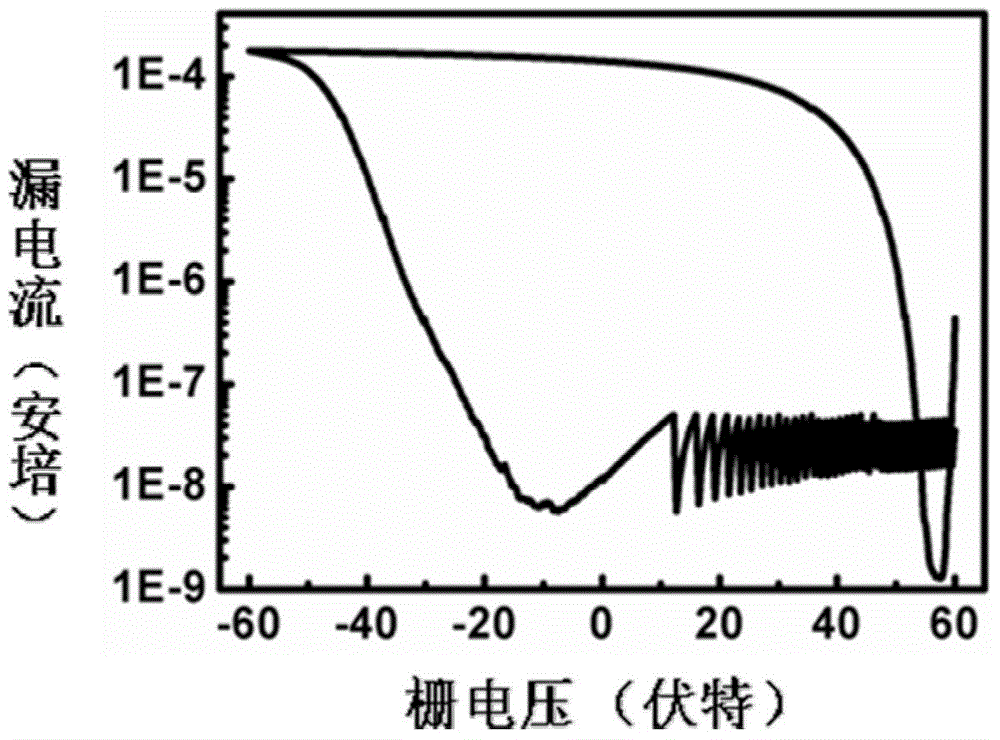

[0029] After the glass substrate is cleaned, it is blown dry with nitrogen or air. First, a large-area ITO electrode array is printed on the glass substrate by aerosol inkjet printing. After drying, in order to make the ITO electrode conductive, the printed ITO electrode is placed on the Anneal in the air at 500°C for 30 minutes; then deposit a layer of aluminum oxide dielectric layer on the surface of the ITO electrode by atomic layer deposition, and then print a pair of ITO source and drain on the top of the ITO electrode by aerosol inkjet printing A 200-micron-wide channel is formed between the source electrode and the drain electrode, and the ITO source and drain electrodes are placed in the air and annealed at 500 ° C for 30 minutes, and then ultrasonicated in ethanol, acetone and pure water respectively. Dry it for 5 minutes; finally soak the whole glass substrate in the toluene solution of P3DDT-P2 for 6 to 12 hours, take out the electrodes, rinse them twice with toluene...

Embodiment 2

[0032]Select a flexible polymer substrate such as a PI substrate (which can withstand high temperatures of 280 degrees), clean it and blow it dry with nitrogen or air. First, use aerosol inkjet printing to print a large-area silver electrode array on the PI substrate. After drying, in order to make The silver electrode conducts electricity, and the printed silver electrode is placed in the air and annealed at 200°C for 30 minutes; then a layer of hafnium oxide is deposited on the surface of the silver electrode by atomic layer deposition, and then printed on the silver electrode by aerosol inkjet printing. Print a pair of silver source and drain electrodes on the top of the electrode, and form a 150 micron wide channel between the source and drain electrodes, and place the silver source and drain electrodes in air and anneal at 200°C for 30 minutes; finally put The entire flexible PI substrate was soaked in the toluene solution of PFO-CG200 for 6-12 hours, then the electrodes w...

Embodiment 3

[0034] Select a flexible polymer substrate such as a PET substrate, clean it and blow it dry with nitrogen or air. First, use the transfer printing method aerosol inkjet printing to print a large-area silver electrode array on the PET substrate. After drying, in order to make the silver electrode conductive , place the printed silver electrode in air and anneal at 200°C for 30 minutes; then deposit a layer of aluminum oxide on the surface of the silver electrode by atomic layer deposition, and then print on the silver electrode by aerosol inkjet printing A pair of silver source and drain electrodes, a 100 micron wide channel is formed between the source electrode and the drain electrode, and the silver source and drain electrodes are placed in the air and annealed at 200°C for 30 minutes; finally the entire glass sheet Soak in the m-xylene solution of F8T2-P2 for 6 to 12 hours, take out the electrode, wash it twice with m-xylene, and measure the electrical properties. The mobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com